international

construction

november 2014

ROADBUILDING

28

Project pressures

Emissions and fuel savings

Atlas Copco’s large pavers have been fittedwith Stage IV engines

A

tlas Copco has updated its large paver rangewith new engines that complywith

Stage IV/Tier 4 Final emissions regulations in Europe, Japan and theUS. The

company says that annual fuel savings could add up to 4,200 litres per year, which

means an 11 tonne reduction inCO

2

aswell as a cut in the pollutants targeted by the

legislation.

Atlas Copco uses a diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR)

to achieve emissions compliance, and has alsomade new updates to other aspects of its

pavers.

The SD2550CS has a new dashboardwhich has been ergonomically positioned and

designedwith easy to understand analogue signs in a digital display. Toggle switchesmake

life easier for operatorswearing gloves.

The SD2550CS is suitable for highway paving up to 14m, with a

theoretical production capacity of 1,100 tonnes per hour. It comes

with a15 tonne capacity hopper, awidematerial tunnel and 500

mm diameter auger. Screed choices include the V5100/6000 TVE

(tamper vibration) screeds, V5100/6000TVH (high compaction)

screeds aswell as theR300TVE rigid screed.

Another interesting feature is the VarioSpeed option

which recognises the engine revs required for any

given task and adjust the speed

accordingly. Atlas Copco says

this could save up to 15% in

fuel costs aswell as reducing

unnecessarywear on the

machine.

first, which was no problem for the

versatile 3800CR.

Once this was out of the way, the task

of recycling to a depthof 100mmbegan,

with themilledmaterial beingmixed as it

was cut in a single pass with a pre-spread

layer of cement binder.

Water and bitumen emulsion – foamed

bitumen – were injected into the 3800

CR mixing chamber via injection bars

from a water and binding agent tanker

travelling in front of the machine.

Once mixed, the conveyor transferred

the material to the Vision 5200-2 paver

for laying and pre-compaction as a new

course.

Mark Stahl, vice president for operations at Dunn Company

said, “Cold in-place recycling (CIR) is a good complement to

traditional constructionmethods. By re-usingmaterials in-place

for the intermediate layer, we help the wearing courses perform

better while reducing the time, cost and environmental impact

of projects. That benefits agencies as well as the taxpaying

public”.

The jobwas successfully completed in time.Thiswas naturally

not only great news for Dunn‘s client, but the contractor also

profited from the prompt completion of the project, and the

next job is already lined up for the 3800CR – this time not in

cold recycling, but inmilling.

Recyclingwork

In a similar application, Brown Brown, a road building

contractor, in Santa Teresinha in the state of Bahia, Brazil has

completed rehabilitationwork on portions of highway BR-381

from Sao Paulo to Belo Horizonte. The company worked

with technical staff from equipment supplier

Roadtec to carry out the work with a cold in-

place recycling (CIR) process tailored for the

tropical climates and for roadways with heavy

traffic.

The equipment train for this consisted of a water truck in

>

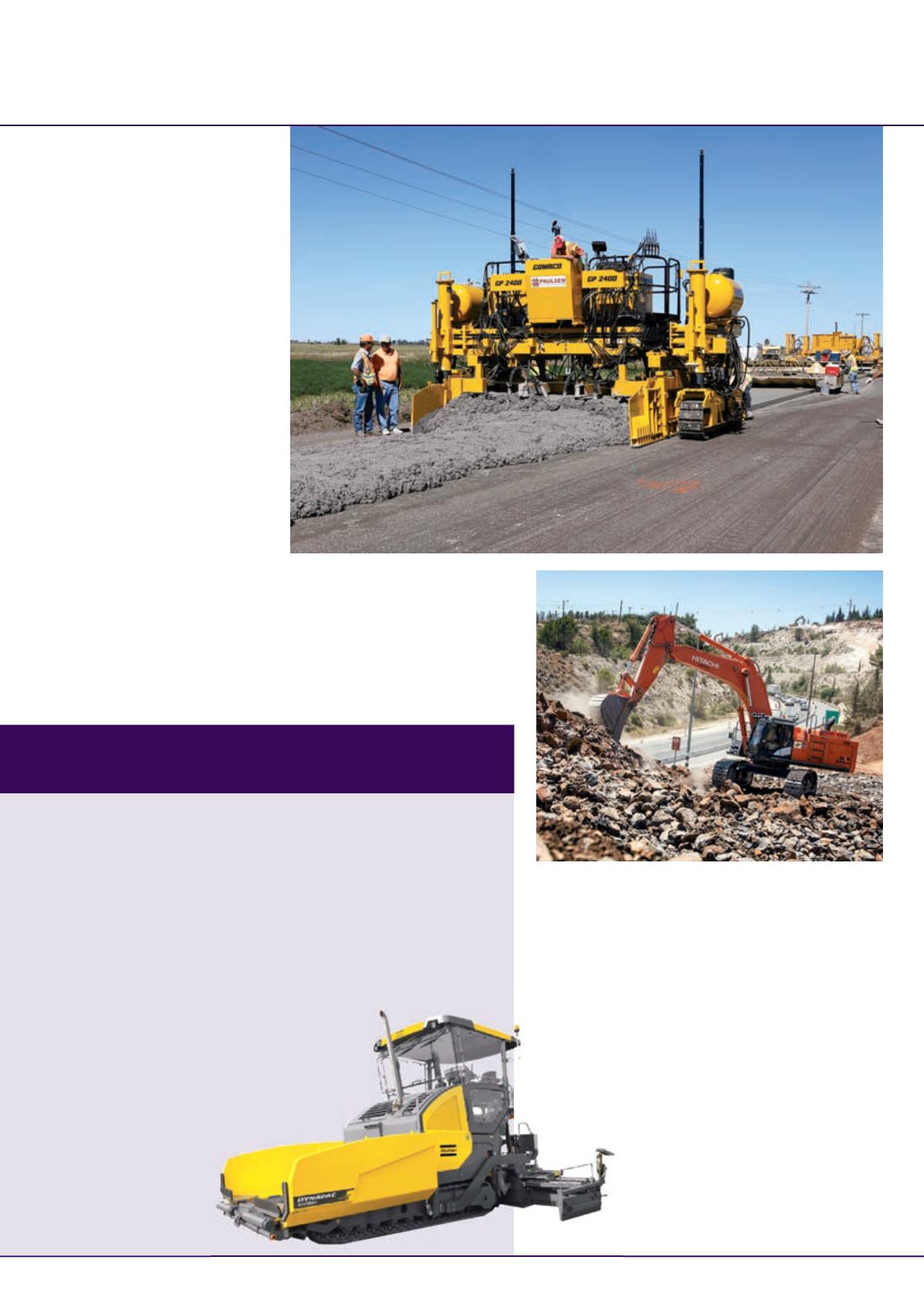

Nebraska-based contractor Paulsen

achieved advance rates of more

than 1.5 km per day on a local

resurfacing job using a GOMACO

two-track GP-2400 paver fittedwith

a Leica Geosystems 3D guidance

system.

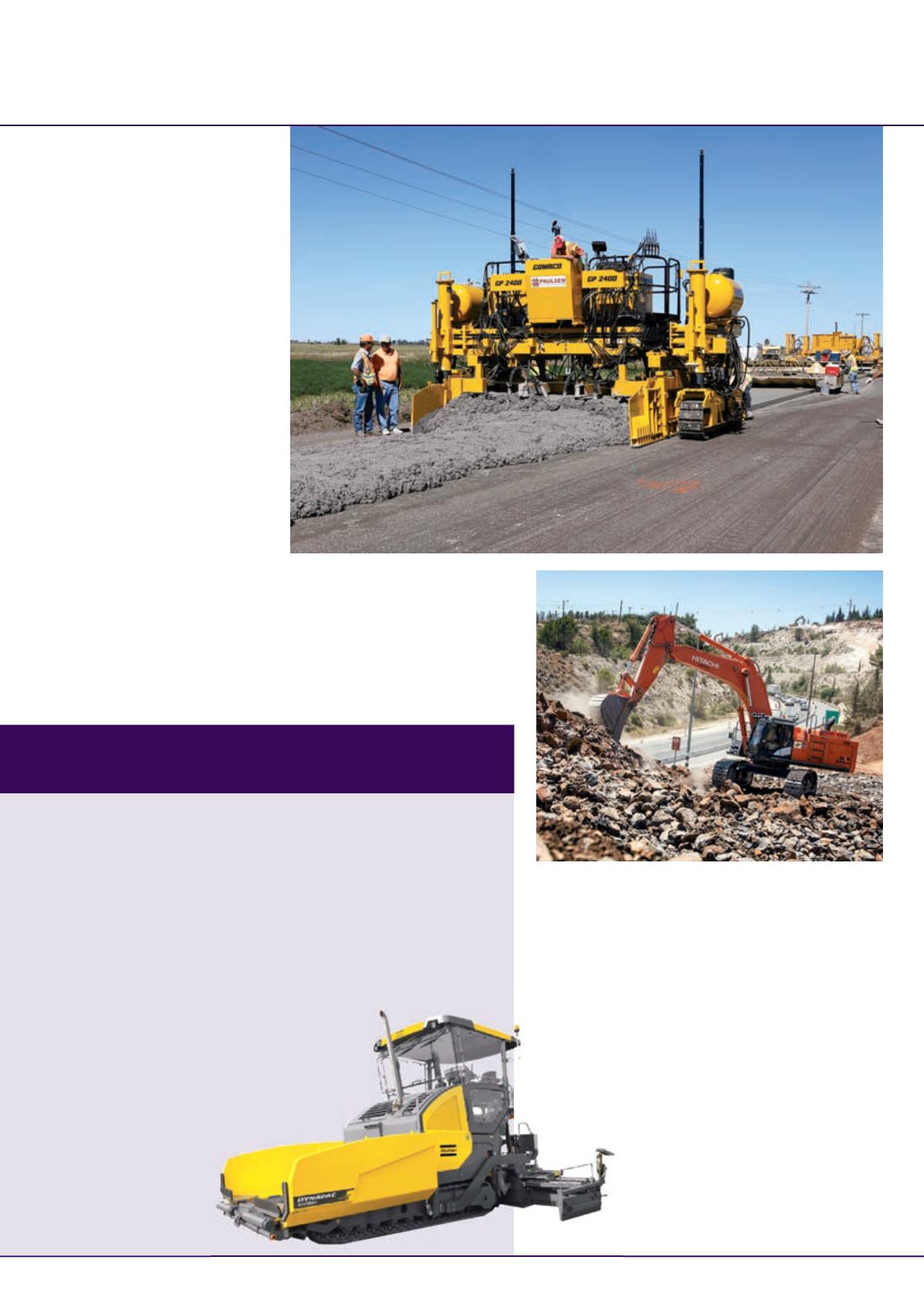

Hilkiyahu is using a 65 tonne class Hitachi ZX670LCH-5

to help excavate and load 1.5millionm

3

of materials on

the upgraded of a 13 km stretch of Israels’ Road 65.

The company has praised themachine’s productivity,

stability and operator visibility.