43

d

&

ri

MARCH-APRIL 2015

EQUIPMENT

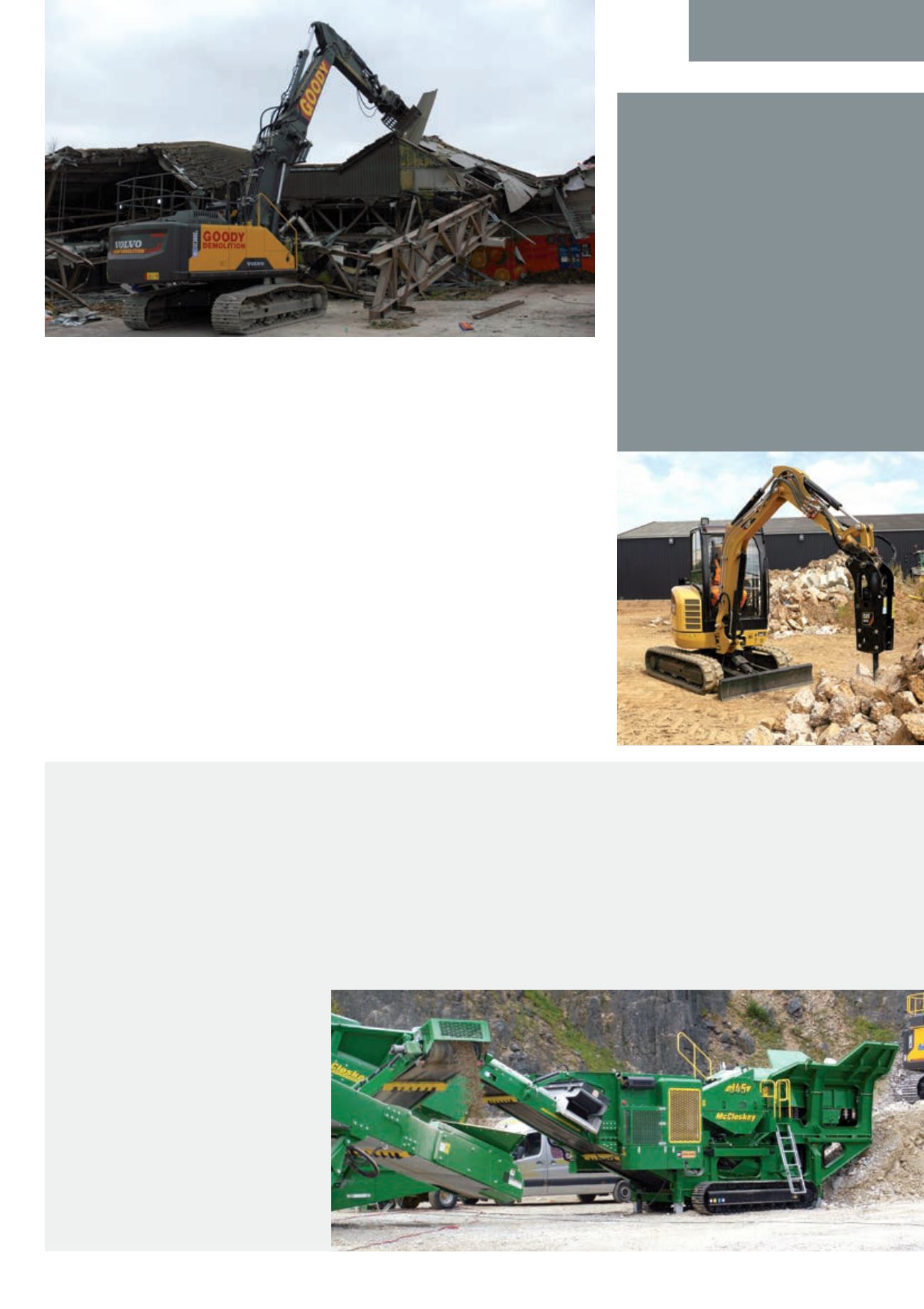

Goody opts

for Volvo duo

K

ent,UK, based contractorGoody

Demolitionhas takendeliveryof two

newVolvodemolition excavators that

bothmeet the latest Stage IV engine emission

regulations.

The firstmachine, a 25 tonne class

EC250E, has been specified for secondary

demolition applications andhas been

suppliedwith the standardbackhoeboom

configuration, while the larger 30 tonne

classEC300Ehas beenmodifiedbyKocurek

Excavators to feature amodular boom

joint and22m (72.2 ft) threepiecehigh

reachboom aswell as a straight boom.

It alsonow features a titling cabwith full

FOGSprotection and additional ‘cassette’

counterweight to ensure stabilitywhen

operating at full heightwith a 2.5 tonne tool.

Bothmachines havebeen suppliedwith

twin lockquickhitches, full guarding around

the superstructures and additional hydraulic

circuits to facilitate grab rotation for the

wide rangeof demolition attachments used

byGoodyDemolition that includes shears,

grapples andpulverisers. Power comes from

aVolvo eight litrediesel that delivers 159kW

(213hp) on theEC250E and179kW (240hp)

on theEC300E.

■

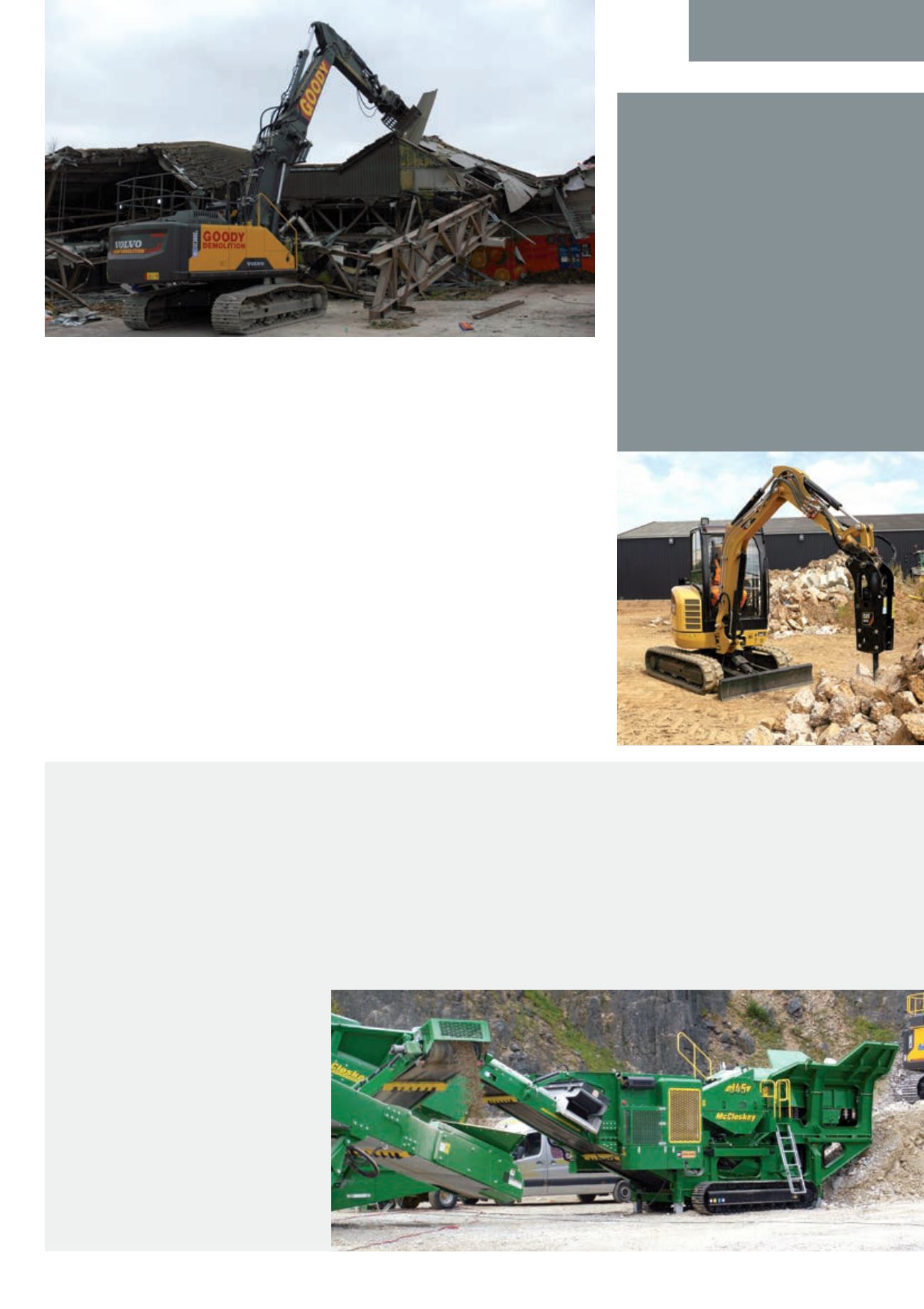

Cat has introduced four new hydraulic breakers

in the E Series to replace their D Series

predecessors. The 130 kg (286 lb) H35E, 250

kg (550 lb) H45E, 340 kg (748 lb) H55E and

380 kg (836 lb) H65E are available in two

mounting configurations for installation on both

Caterpillar and other carrier brands. All four are

also available as silenced versions (with the ‘s’

designation following themodel number) that use

a fully enclosed housing to suppress noise.

Theymatch auxiliary flows and pressures of

Cat machines. Flat-topmodels allow versatility

for installation on equipment made by other

manufacturers. Pin-onmodels are available for

the H55E and H65E in applications that require a

dedicated hammer-equipped Cat machine.

The suspension system on the silencedmodels

include buffers to absorb forces and isolate them

from themachine and a suspension jack dampens

vibration and sound. The result is quiet, reliable

operation and reduced operator fatigue.

Goody’s new Stage IV Volvo EC300E features a Kocurekmodular joint, a tilting cabwith full FOGS protection and

additional counterweight

McCloskey teams up with Volvo Penta

Mobile crushing and screening producerMcCloskey will nowmake use of Volvo Penta engines in its product ranges after a two year

development process. Volvo Penta’s D8, D11 and D13 engines will be fitted toMcCloskey’s impact and jaw crushers, with the D6 unit going

into its screens and trommels.

These engines comply with Tier 4 Final/Stage 4 regulations without the need for either DPF or DOC.

Over the last two years, regular meetings were held between the two companies with constant contact beingmaintained not only with

Volvo salesmanagers and engineers but also a business development manager.

“That, for us, was one of Volvo Penta’s key selling points,” said John O’Neill, vice president of sales andmarketing forMcCloskey.

“We work closely with our customers in the research and development stages of all our products, and Volvo Penta showed the same

commitment to listening to our requirements and delivering the right solution.”

Volvo Penta’s team of engineers also worked closely withMcCloskey’s engineering department to ensure that an engine package was

produced that fitsMcCloskey’s unique

needs, with engine assemblies, including

heavy-duty cooling packages, being

customised for a perfect fit.

To further demonstrate its versatility

and dedication, Volvo Pentamounted a skid

to the bottom of the engine and heavy-duty

cooling package so that the engine would

slip right into themachine.

“Being attuned to our needs is a key

requirement for our partners,” John went

on. “Volvo Pentamade sure the engines

were perfectly suited to working in some

of the harshest conditions worldwide, from

the Arctic Circle to the heat of the outback

in Australia.”