38

MARCH-APRIL 2015

d

&

ri

SITE REPORT

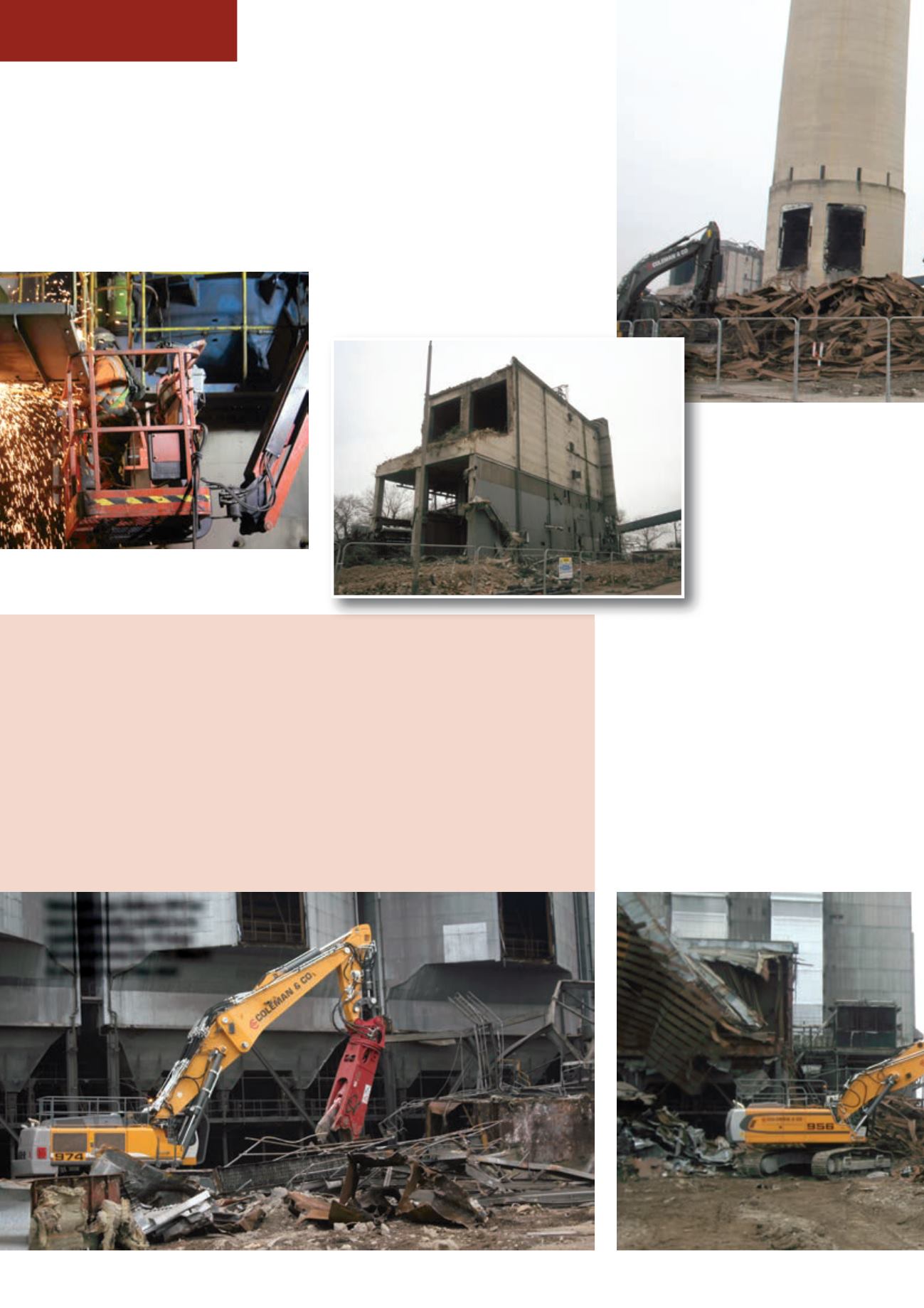

The only remaining structure from

the coal plant, with the rest being

the first to be removed

03.00 and05.00 am and the towerswere

eventuallydemolished at 05.01am.Despite

the earlyhour of the implosion, the event

proved amajor draw for the local population,

with several thousand turningup to view the

removal ofwhat hadbeenmajor features of

the local skyline.

Demolition thenbeganon the core

plant (coal plant, turbinehall, boilers and

precipitators) inDecember 2014, andby the

timeof

D&Ri’s

visit, the turbinehall had

been almost completely clearedof plant.

According to sitemanager JohnFoster, the

initialworkwas external to themainplant.

“With just threemachines, wedismantled all

the conveyor belts and removed the entire

coal plant from the owner’s land. In addition,

anything at height had tobe removedbefore

thenesting season started to ensure therewere

nodelays caused to thedemolition. The actual

demolition reallybegan inApril 2014.”

Johnwas relaxed about the challenge

Coleman faces in carryingout thework,

havingbeen involvedwithpwer stations all

of hisworking life– first in

their construction andnow

their demolition, but hewent

on: “One of the challengeswe

face is finding capable local

operatives. Currently there

are around120workers on

site, with55of thesebeing

our employees and the remainderworking

for our asbestos remediation sub-contractor

OCS. At peak, therewere 175personnel on

site, withmost of the additionalworkers also

working forOCS.We are currentlyoperating

13machines, including thenewLiebherrs,

although the job is such thatwe could just

use 11. The additional ones giveus cover in

the event ofmachinedowntime and should

Colemanget busier and themachines be

requiredonother sites, thenwewill transfer

them across,” said John.

The scaleof thedemolition is impressive,

with a substantial tonnageofmetal to

beprocessed and recycled. All arisings

are cleaned and separated in the various

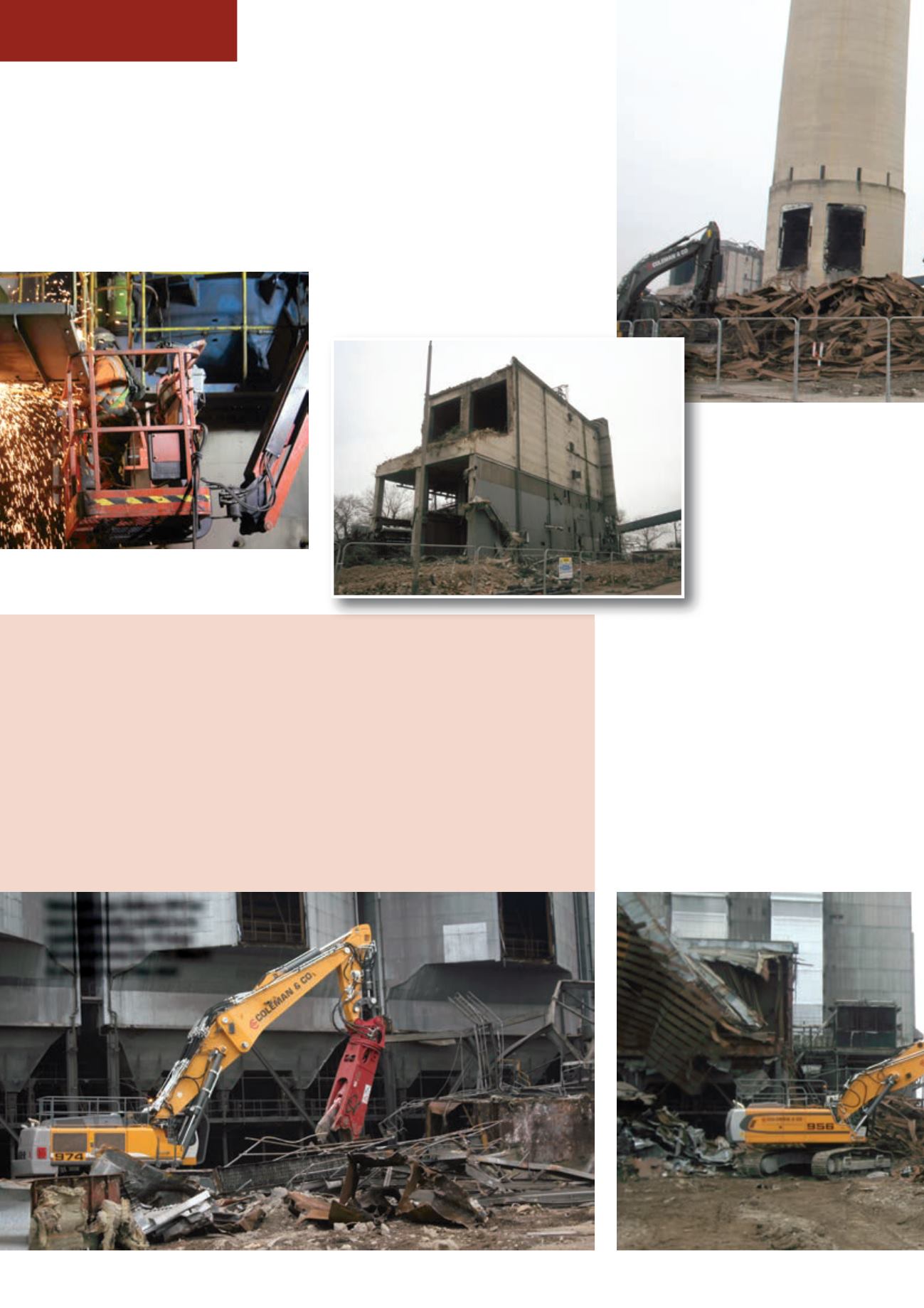

Heavy duty metal

The flagship of the six Liebherr excavators delivered to Coleman & Company as a result

of the company commencing work on the Didcot A power station demolition is this R974.

Themachine has beenmodified to carry a 14 tonne Stanley LaBounty MSD 7500R-SL

demolition shear. To achieve this, Liebherr added a 6m (19.7 ft) extension to themain

boom and a 2.9m (9.5 ft) stick fitted with a heavy duty super mass excavation cylinder.

In addition, themachine sports uprated hydraulics and a special by-pass valve has been

fitted on the shear to generate less back pressure and thereby improve fuel economy. The

machine carries the same counterweight as used on the 43m (141 ft) high reach version

of the 974, giving an overall machine weight of 130 tonnes. Liebherr has rated the

machine for full 360° operation, as is the case with all its demolition excavators. Similar

modifed 974s have been supplied to French contractors Cardem and Brunel. The new

machine now gives Coleman the capability to process heavy duty steel scrap fromDidcot

and other future industrial demolition projects.

Some 70,000 tonnes of boilers, flues, ducting and

other elementswill be removed by the time demolition

is completed

Coleman’s new Liebherr 974 has

been specificallymodified to be

capable of wielding a 14 tonne

Stanley LaBounty shear to allow it

to process heavy duty steel

One of Coleman’s high

reaches atwork removing

plant from themain power

station structure