49

d

&

ri

MARCH-APRIL 2015

IN ACTION

U

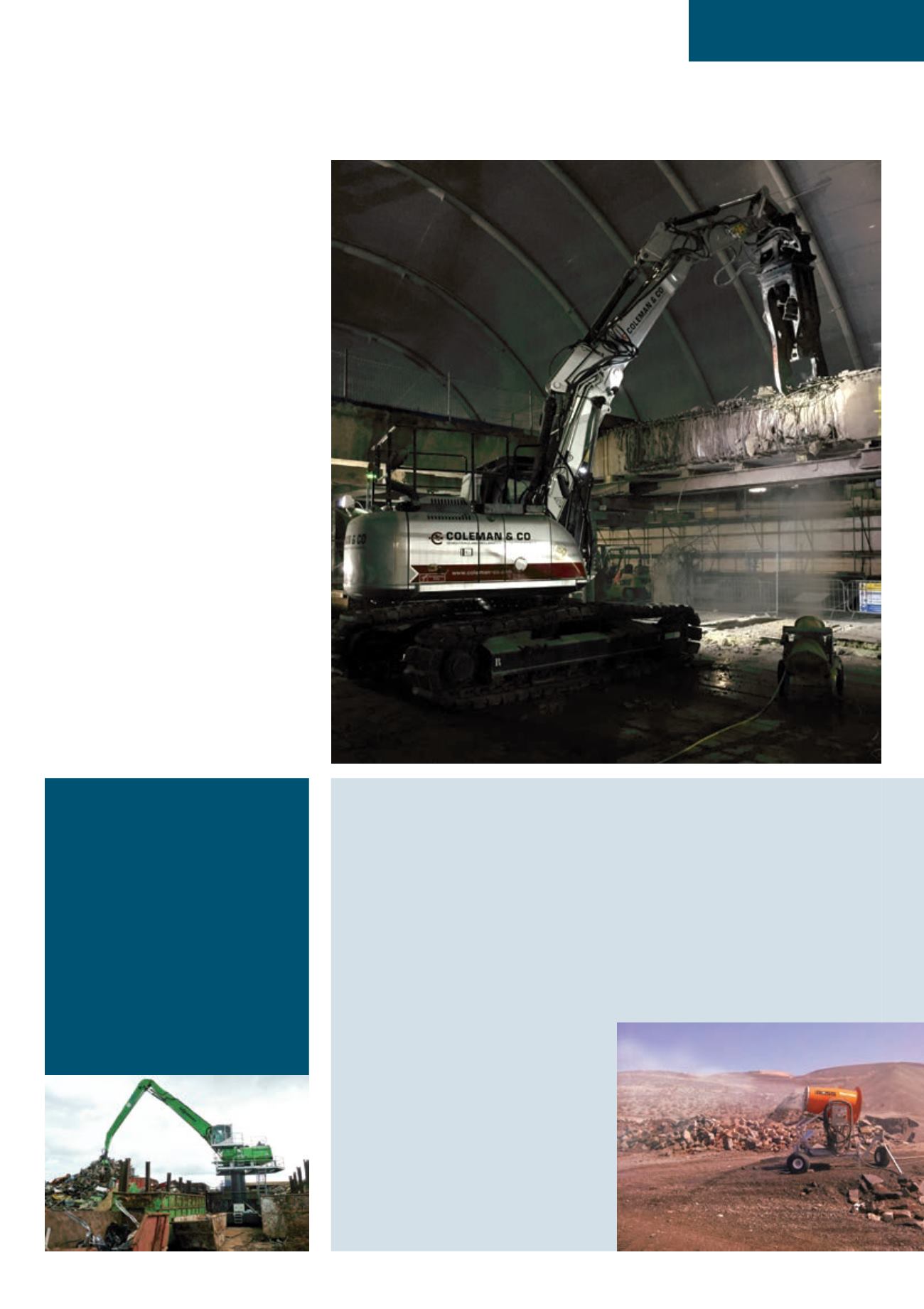

K contractorColeman&Company

is using a speciallydeveloped remote

control JCB excavator sporting a 4

tonnemultiprocessor to remove reinforced

concrete floors duringongoingdemolition

work at BirminghamNewStreet Station. The

machine is a 21 tonne excavator that combines

a JCB JS190upper structurewith a JS220LC

undercarriage and rubber trackpads that

allows it todeploy a 4 tonnemultiprocessor

without exceeding a grossmachineweight of

25 tonnes.

Coleman is now in its fifth year on site

and the current phase requires the removal

of 6,000 tonnes ofmass reinforced concrete

during2014 and2015. Somebeamsweigh as

much as 90 tonnes and are 2.5m (8.2 ft)wide

and1.5m (5 ft) deep. Thework is takingplace

directlybeneath thenewly constructed,multi

millionpound atrium steelwork structure that

must beprotected from any impact from the

demolitionwork. It is also takingplacewithin

a live construction sitewhile 140,000people

continue to travel through the stationdaily.

Coleman&Company technicalmanager

ChrisHolland said: “We asked JCB todesign a

bespokemachine that could carryout specific

tasks inhigh risk and technically challenging

environments. The stakes are veryhigh at

NewStreet givenwe’ll be operating above

12 live train lines carrying thousands of

passengers per day.”

Thenewmachine is expected towork

on theproject for thenext ninemonths.

Therafter, itwill provideColemanwith a

unique tool for use in any futurehighly

complexdemolition tasks.

■

Spray in control

A Californian recycler is using a DustBoss DB-45 atomised water mist generator to

control dust at its Chula Vista facility, which sees dozens of dump trucks deliver recovered

road surfacing and demolition waste every day. Reclaimed Aggregates Inc, formed in

2005 as a subsidiary of Pavement Recycling Systems, added the Chula Vista site to its

two other locations in Colton and Lancaster in 2009.

The former is now its largest location, where it processes concrete and asphalt.

Material is offloaded onto a 61m (220) square dry earth receiving area and immediately

moved by front loader to the crusher or into storage piles, creating a large volume of

dust as a result. RAI first tried a sprinkler system to control this dust, which was causing

issues for adjacent businesses, but this solution just saturated thematerial to createmud

but dust was still an issue.

RAI then tried the DustBoss DB-45 and

found its range well suited to the size of

the area requiring dust management. The

unit is able to throw its atomised plume

46m (150 ft) to deliver effective dust

control over a 1,115m

2

(12,000 ft

2

))

area. When equipped with optional 359°

oscillation, the design can cover asmuch

as 16,875m

2

(74,000 ft

2

) from a single

location.

ADustBoss DB-45 is providing effective dust control

at a concrete and asphalt recycling centre in

California, USA

Cologne, Germany, locatedMax Becker Trading

GmbH has recently taken delivery of a new

Sennebogen 850R Special Electro, which is being

used to charge scrapmetal shears aswell as

for general sorting. The 850R Special is fitted

with a 250 kW (336 hp) electricmotor that saves

50% in energy and operating costs compared to

the diesel-poweredmachine it has replaced. The

reach of over 20m (66 ft) covers an area of just

under 1,300m

2

(13,994 ft

2

). Thanks to the crawler

undercarriagewith a 4.9m (16 ft) trackwidth, the

machine is extremely safe but can also be easily

moved over the entire compound. The cab has been

raised by 5m (16.4 ft) through the use of a pylon

that, combinedwith the 1m rigid cabin elevation,

gives clear visibility over theworking envelope

during shear charging duties.

Remote in control

The remotely controlledmachine

developed by JCB for Coleman

& Company has a JS190 upper

mounted on a larger JS220LC

undercarriage to keep the

weight, including 4 tonne tool,

below 25 tonnes