55

LOW-LEVEL ACCESS

NOVEMBER-DECEMBER 2013

ACCESS, LIFT & HANDLERS

because of their weight, they typically can’t

access work on freshly poured concrete until it

has fully cured, which could take up to 30 days

and delay projects.

Since taller, over-19-foot lifts can weigh as

much as 3,300 pounds (Terex AWP's GS-1930

weighs 2,702; MEC Aerial Work Platform's

1932ES weighs 3,060 pounds; Snorkel's 1930E

is 3,160 pounds and Skyjack's SJIII 3219 comes

in at 2,580 pounds), contractors and operators

must know floor load limits. Low-level lifts can

weigh as little as 600 pounds and some feature

dual front wheels that help disperse the weight

and wheel-load concentration. Together, those

aspects allow operators to tackle projects on

freshly poured concrete sooner and access jobs

on delicate flooring with no damage.

To further prevent damage in finished spaces,

many units - both 19-foot and below - also

feature non-marking wheels that prevent scuffs

on hard surfaces.

Some low-level lifts also are equipped with

counter-rotating wheels; while one wheel

rotates down, the other rotates up. This

motion reduces the friction point so the lift can

maneuver over carpet without causing tears.

Heed the hydraulics

Heavier lifts aren’t the only thing that can

damage floors; hydraulic systems can be a

culprit, as well. Hydraulic systems that operate

the lift’s steering, driving and lifting have more

doorways in commercial applications. However,

those with higher stowed heights can make

ducking under doorways or into elevators with

drywall or framing on board nearly impossible,

and it limits the range of work that can be

performed with the lift. Also, lifts with wider

turning radiuses might not be able to maneuver

around tight corners.

Low-level scissor lifts can be as narrow as

25 inches, and some feature stowed heights as

low as 66 inches. This provides more clearance

for getting under doorways and into elevators,

even with taller materials on board. Low-level

lifts also feature platform lengths as short as

47 inches, so they can easily fit in any elevator

in the United States that’s built to code. In

addition, some models allow operators to turn

in shorter radiuses, some as low as zero, for

easier maneuverability around tight corners and

into hallways or small offices without assistance

from other crewmembers.

A tough climb

As mentioned earlier, using low-level lifts

increases efficiency and productivity. More

important than those benefits, however,

is the impact these lifts have on worker

safety, especially when compared to ladders.

According to OSHA, falls from ladders are one

of the leading causes of occupational injuries

and fatalities. The risk is so great that some

countries have enacted strict regulations on

their usage. Users also can suffer from less

serious injuries like bruising and tenderness

on the soles of their feet from standing on a

ladder’s narrow rungs for extended periods of

time. While there are times, places, and projects

for ladders, general contracting or maintenance

jobs usually aren’t among them.

The final show

Nineteen-foot scissor lifts might take you a little

higher than low-level lifts, and they are certainly

safer than ladders. But when comparing what

really matters on a jobsite, it goes beyond

simple height capabilities.

The benefits of the thoughtful design of low-

level scissor lifts aren’t just smoke and mirrors.

Whether you’re hanging drywall, installing

sprinkler systems, painting or doing electrical

work, your lift’s features should allow you and

your employees to get all these jobs done safely

and easily. With 14- to 20-foot working heights,

low-level lifts are revealing that the “higher is

always better” perception is the real illusion.

■

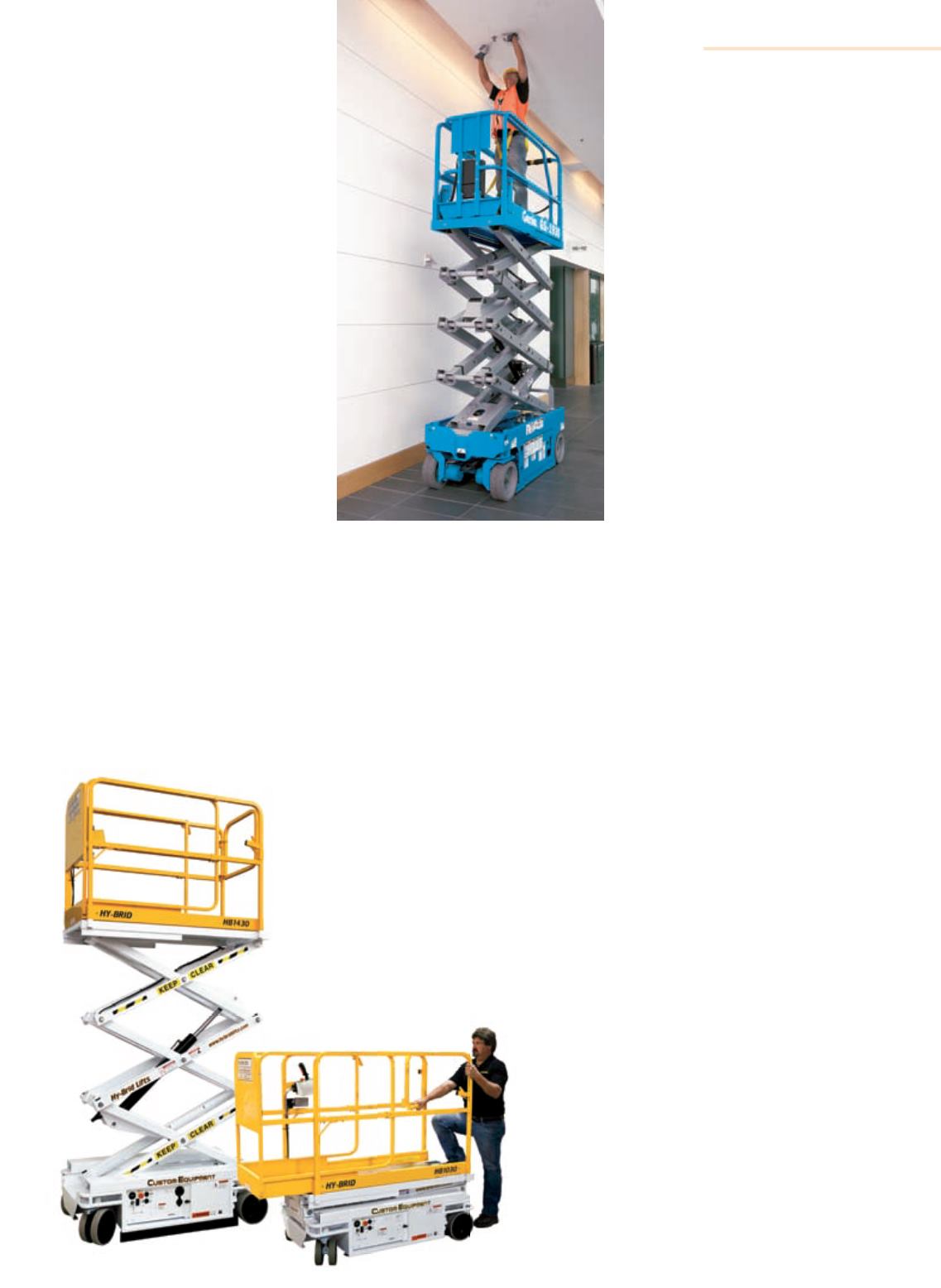

The Genie GS-1930 self-propelled scissor

lift comes standard with a low-emission

electric drive that delivers a quiet,

convenient method for operation in sound-

sensitive environments. The units’ narrow

profile, 2 feet 6 inches, allows it to pass

through standard doorways, and with its

turning radius of 5 feet 1 inch, this scissor

lift is ideal for working in office buildings,

shopping malls, hotels, schools and more.

Low-level

scissor

lifts allow

users to

accomplish

general

contracting

projects at

working

heights up to

20 feet.

routing with six to eight connection points. If

these points become loose, fluid can leak and

damage carpeting, which will require costly

replacement. Not only that, but fluid that leaks

onto hard surfaces like tile or laminate creates

slip hazards. Some rough terrain and electric

scissor lifts feature hydraulic steering, driving

and lifting, which means there is an increased

risk for damage and safety incidents.

The hydraulic system on low-level lifts

typically only powers them up and down, while

battery power operates the driving and steering.

This configuration has only two connection

points, so the chance of a leak is greatly

reduced. Some low level scissor lifts even

feature a fully contained hydraulic system, so

even if a leak occurs the fluid does not escape

to damage carpeting or create hazards.

There are, of course, many options to avoid

hydrualic leaking, including equipment diapers

and other types of spill-proof solutions.

Getting around (or under)

Maneuvering between studs and walls,

around tight corners or into small spaces can

be challenging with a lift. Many are no wider

than 32 inches, well within the width of most

number