46

ACT

APRIL 2015

PRODUCT FOCUS

SPMTS

equipment pairednicelyon increasingly

heavier andmoredifficult jobs.

“Engineerswould sayhey, there’s this

equipment out there, there is away to

move it,” saidFischer. “So really, together

as cranes got stronger and stronger, the

SPMTs allowed the industry tobuild

bigger andbigger.And they’re still

growing. Sincehey, noproblem, put eight

SPMTsunder it insteadof six.”

Reliability iswhat Scheuerledepends

on. If one transporterdoesn’t function,

the complete systemdoesn’t function.

Software, then, iswhereSPMTswill

continue togetmore advanced.AsFischer

said, yougrowwithyour customers.

“It’s all about the software,”he said.

“Youhave a computer system andyour

customer comes toyou and says ‘Hey

wewant touse it thiswayor thatway,

wehave anSPMThere andhere, how

doweprogram them to talk?’ Software

development goes on andon andwe learn

fromour customers. They comewith the

needs,we find a solution.”

Scheuerlehas built 12,500 axle lines

of the8-foot SPMT. Fischer,whohas

been in the industry eight years, guesses

that’s about 80-85percent of themarket.

Recently they cameupwith an “arctic”

version that canoperate in -40F aswell

as tropical conditions and a “fast” version

that can travel up to14mph, depending

on thepayload.Aswell, they’ve about

doubled the capacity the8-foot SPMT

since the1980s.

Scheuerle is oneof three companies

that belong toTransporter Industry

International (TIIGroup).

60 tons per axle

Cuneo, Italy-basedComettomanufactures

a lineof threeSPMTs,with a fourth

currently in theworks. TheMSPE40T,

MSPEEVO50T and theMSPEEVO2

60Thave40, 50 and60-ton capacities,

respectively, and a70-tonmodel has

undergone testing.Allmodels are

interchangeable and linkable complete

with electronic steering and twooptions

forwireless remotes.

TheMSPEEVO260Twas released

in2012 and isunique toCometto.

They’ve soldmore than1,000 axle lines

of thismodel in threeyears. It offers the

maximum capacityper the1.4mm axle

spacing configuration: 60 tonsper axle.

TheseSPMTs are currentlybeingusedon

thePanamaCanal expansionproject.

ComettoMSPEEVO260Tswill

transport 16newgates, eachone roughly

100 feet high, 200 feet long andup to

4,000 tons. Themovewill cover a little

over twomilesper trip.

According toTreyLittle, an agent for

Cometto in theU.S.,Cometto is branching

outwith ahandling technlogiesproduct

line called “ComettoHT.”

“Thesewill be smallerunits, same

sort of design, but lighter capacities for

indoor spaces likewarehouses,” saidLittle.

“Some are completely automated, they’ll

followwhite stripes on theground and

things like that. They evendesigned an

explosion-proofmodel.”

Comettohas beenproducingSPMTs

since the1980s alongwithScheuerle and

Goldhofer.

Flexibility pays off

Last yearGoldhofer introduced electronic

steering to their 8-footwideSPMT.

“Thehigher bendingmoment,

additional side stability, thehigher speed

of operation and theusageof standard

components like tires and rims are some

of thekey features of this equipment,”

saidRainerAuerbacher, area sales

manager, heavydutymodules,Goldhofer.

“Besides that, Tier IV final engines and

all the related standards are also available

nowadays.”

TheSPMTmarket is trulyglobal

according toAuerbacher. Thedemand

for equipment inEurope is comparable

toNorthAmerica.Aswell, there are

someunits inLatinAmerican andSouth

America albeit far less thanEurope and

NorthAmerica.

“Nonetheless, huge transport companies

based inEurope andNorthAmerica are

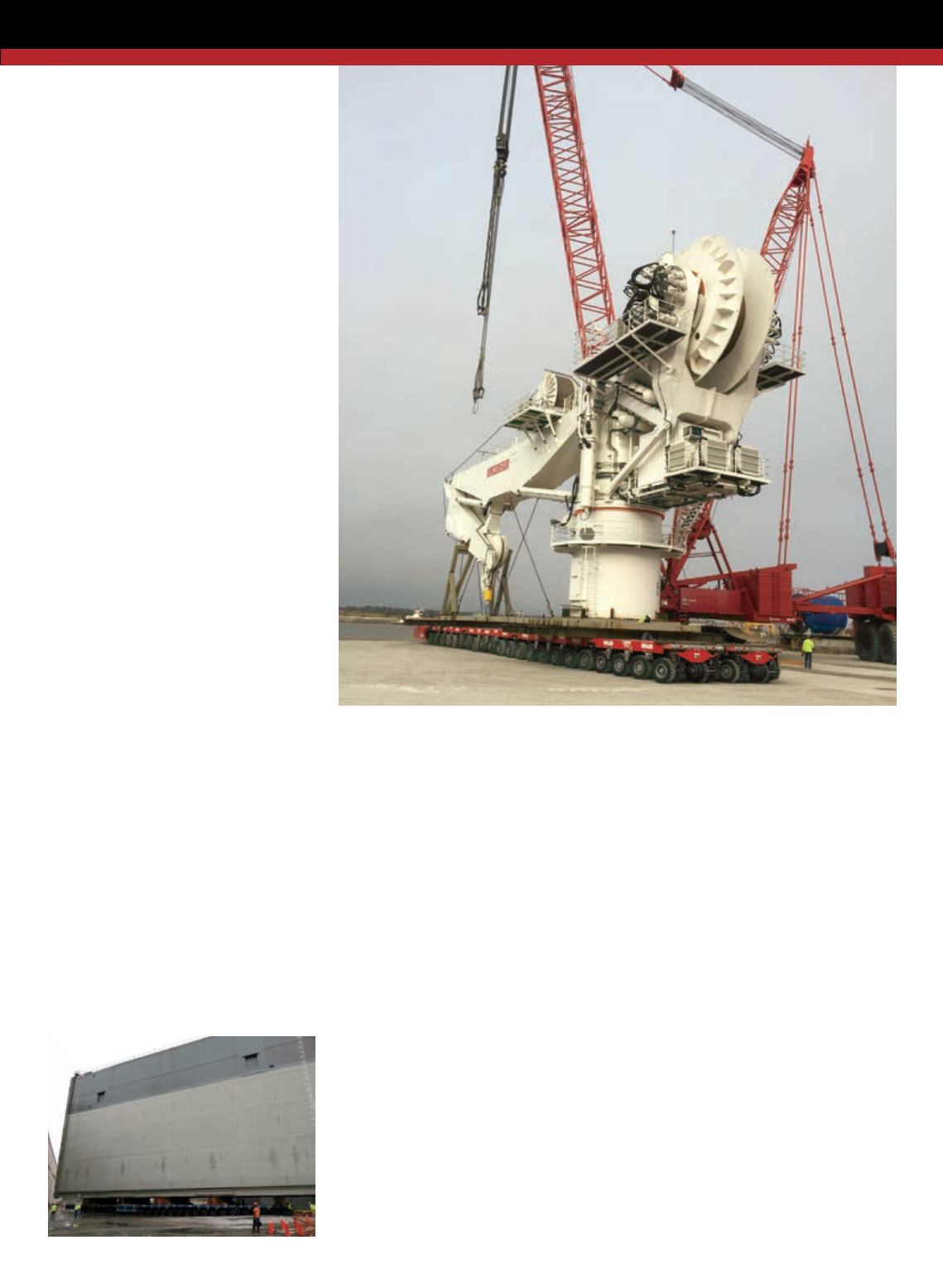

Berard purchased a fleet of Scheuerle Generation 4, 8-foot wide SPMTs in December, 2014.

>48

ComettoMSPE EVO2 60T transporting a

new gate for the Panama Canal.