55

APRIL 2015

ACT

RIGGING

SITEREPORT

Juilian Leek

reports on the

installation of awalkway at

the Port Canaveral Cruise

Ship terminal.

to assist andhandleother sitework.

Therewas also aTerexT344 aerialwork

platformon theproject.

After assembly someof thewalkway

unitsweighed60,000pounds and

measured50 feet long.

Tandem lift

Oneof themost delicate lifts involved

raisingpart of oneof thewalkways in a

tandem lift, stopping to rest the edgeof

thewalkwayon themain support frame,

detaching the front crane, then re-rigging

the lift cable after itwas threaded though

theupper frame.

Clearancebetween thewalkway

and themain framewas less than1.5

inches on each side, however therewere

mountingplates that protrudedout past

thewalkway. Toovercome this, as the

mountswere 90 feet across from each

other, theBeyel craneoperator on the

front cranemoved thewalkway into the

main frame at 22degrees, and then swung

thewalkway135degrees to let theother

mount clear the frame.

One small snagwas amis-manufactured

componentwhichwas reproduced at

Beyel’smachine shop. Beyel’s ability to

reproduce the component kept theproject

on time.

The twomobilepassenger boarding

walkway/bridges/gangways, themselves

worth$4.14million,werepart of the

overall $110million constructionproject.

PortCanaveral is considering the

constructionof yet another large cruise

terminal in2016.

■

©Julian Leek/JNN

I

n thenext fewyearsFlorida’sPort

Canaveral is expected surpass

Miami as theworld’sbusiest cruise

port. In record construction time,

IveyConstructionofMerritt Island

has constructeda190,000 square-foot

passenger terminal in10monthson the

south sideof the channel for theCanaveral

PortAuthority. Thisnew terminal, known

asCruiseTerminal 1,will be able to

handle theworld’s largest cruise ships. The

primaryuserwill beRoyalCaribbean,

whose cruise liner

Quantumof the Seas

is theworld’s third largest cruise shipand

whichwill beusing the terminal on its

port-of-call stops.

Tohandle the largepassenger count, the

new terminal needed amovablewalkway

to access the larger ships’ length and

varyingpassenger door heights. Swedish-

basedFMT-AircraftGateSupport Systems

was taskedwith thedesign, build and

installationof the twomassivewalkways.

After arrivingby ship fromSweden,

the containerswere staged at anon-site

construction area right next to thenew

terminal. Beyel Bros. Crane andRigging,

a local familyowned crane company

located inBrevardCounty justmiles from

theport,was contracted for the lifting

project.

A team fromFMT spent amonth in the

Florida sunshine erecting thewalkways

under thedirectionof Beyel Bros. Crane

andRigging,whichhandled thedelicate

installation job.

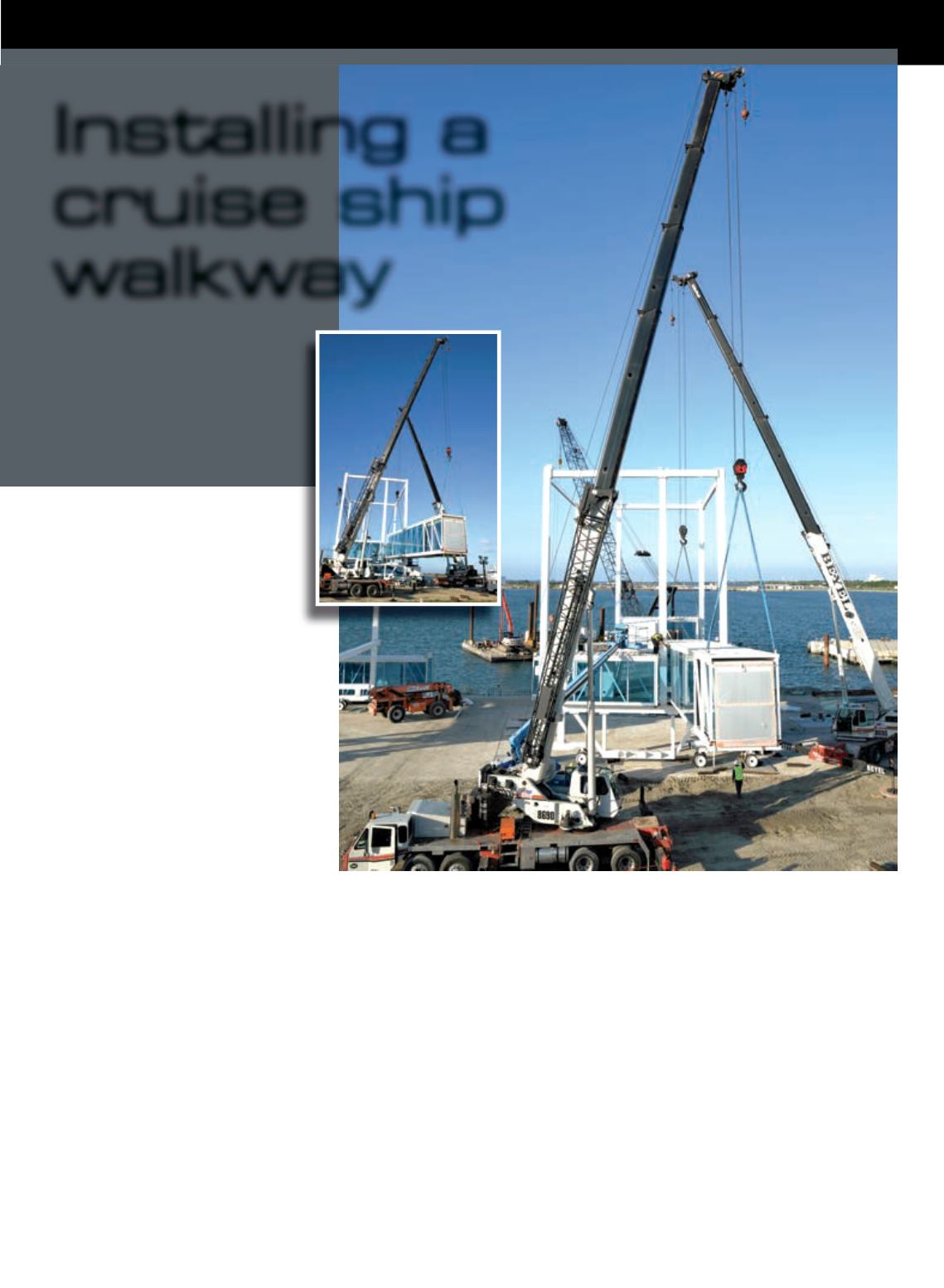

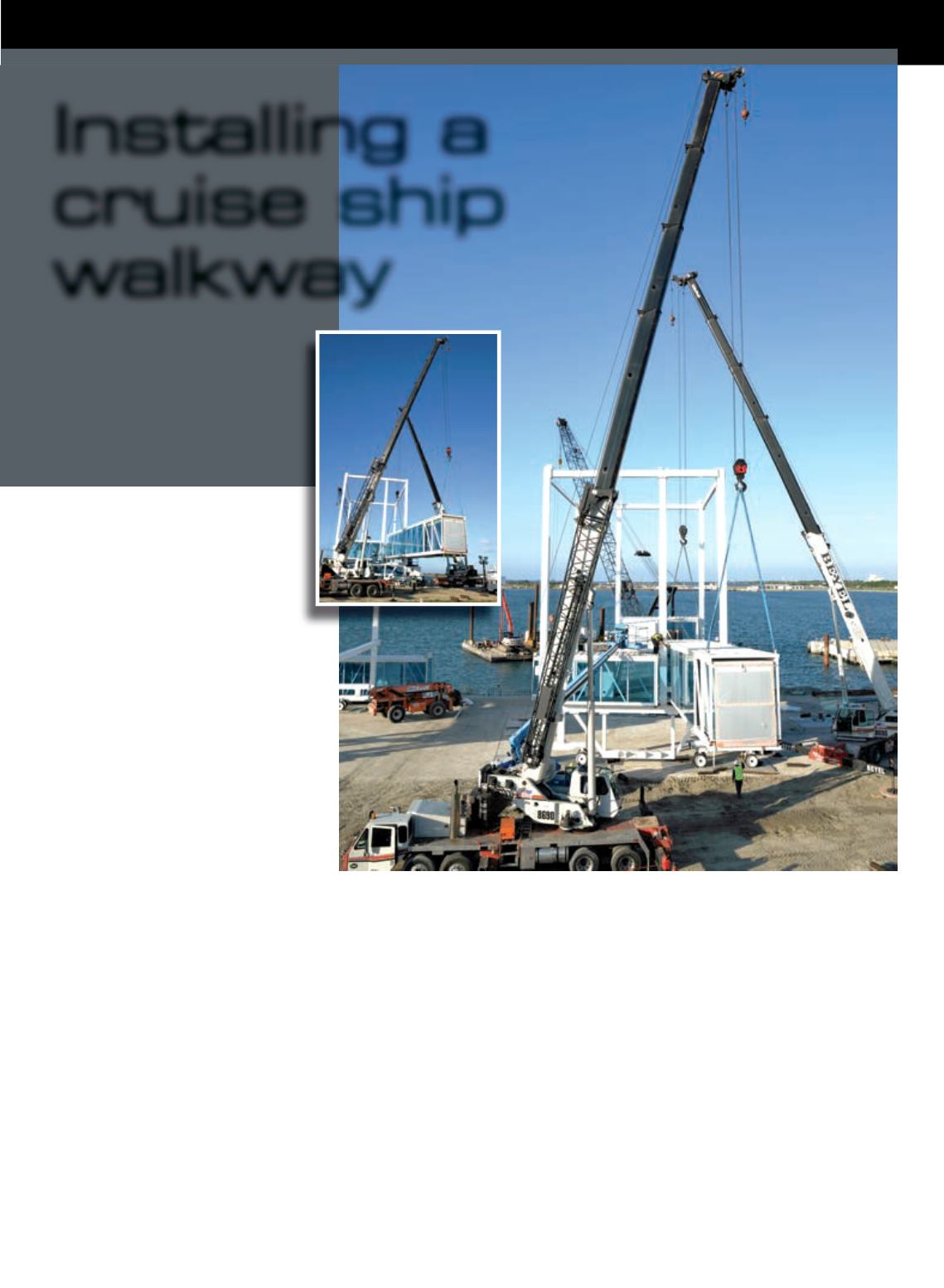

Beyel Bros. dispatched three cranes

to the jobsite, aLink-BeltHTC-8690

and aLiebherrLTM-1080 tohandle the

main lifts plus aGrove 9120 truck crane

Installing a

cruise ship

walkway

Beyel Bros. used

three cranes for

the project, a Link-

Belt HTC-8690 and

a Liebherr LTM-

1080 to handle

themain lifts plus

a Grove 9120 to

handle other site

work.