NEWS

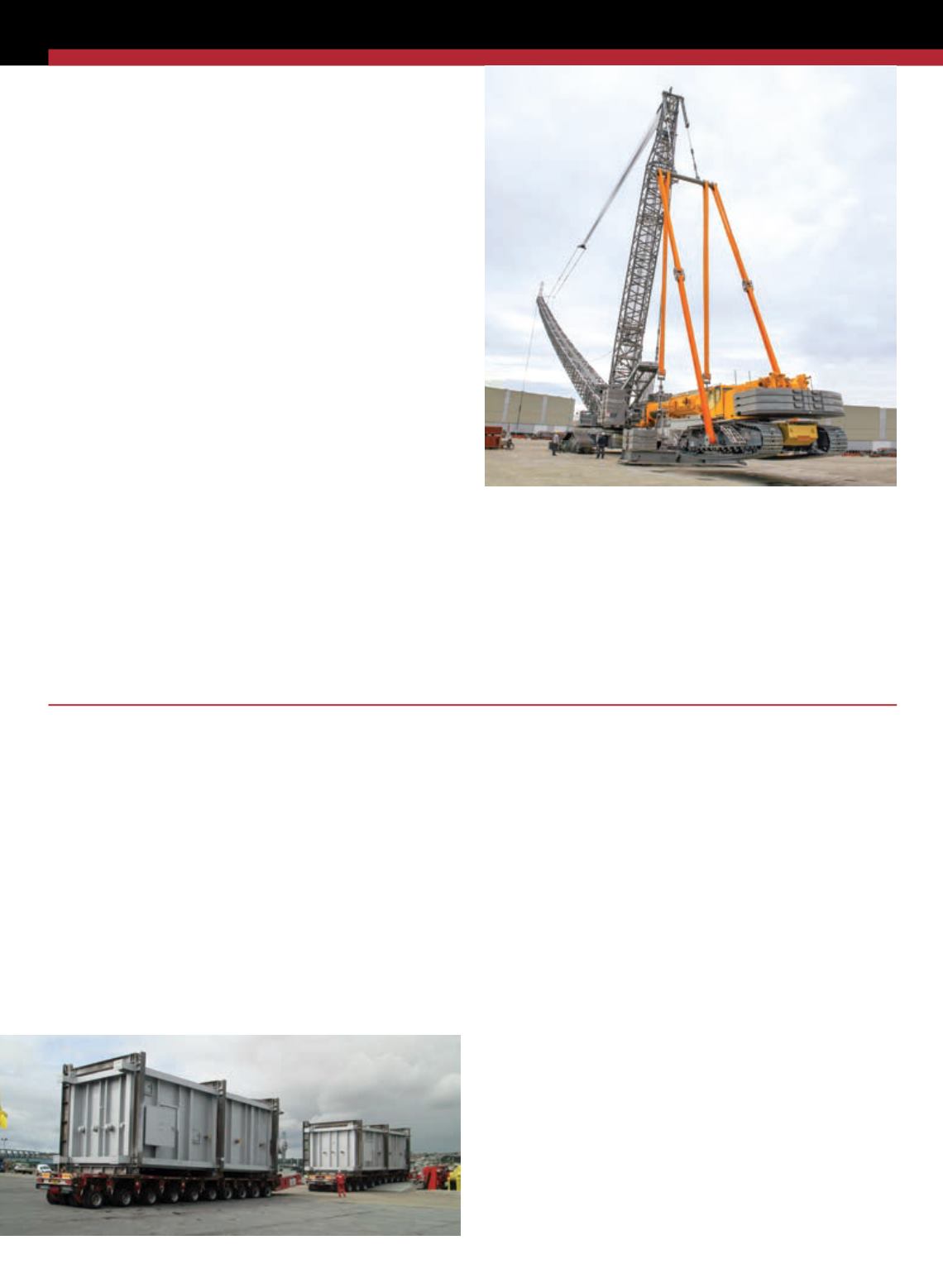

Liebherr has developed anew

system for erecting its 600

metric ton capacityLR1600/2

crawler craneswith longwind

power boom systems.

Insteadof using a large

counterweightwhen

erecting theboom systems,

Liebherr has used anLTR

1220 telescopic crawler

crane as the counterweight

instead.According to the

manufacturer, thisway ismore

efficient, safer and reduces the

amount of ballast that has to

be transported.

Thenew conceptwas shown

at a customer event inAugust

at theLiebherr-WerkEhingen

factory inGermany. For the

demonstration anLR1600/2

was configuredwith an

SL10DFBmainboom system

with amainboommeasuring

153meters long and a

New crawler

erection concept

from Liebherr

12-meter fixed jib.

Normally to erect the

boom in this configuration,

350metric tons of derrick

ballastwouldbe required.

Theballastwould thenbe

reduced to70metric tons for

hoisting the standardwind

turbine components, and then

returned to350metric tons

when lowering theboom.

In total, 350metric tons of

counterweightwouldneed to

be transported to site.

Using theLTR1220 as the

main counterweight, however,

wouldmean that only70

metric tons of counterweight

wouldbe required for use as

suspendedballast, as during

the erection and lowering

of theboom system, an

LTR1220 telescopic crawler

crane couldbeused. For the

demonstration, theLTR1220

was used as a counterweight

and attached to the telescopic

boomusing an adapter.

The crane andballast plate

are attached to thederrick

jibusing a cross beamwith

strap loops.After the erection

process the telescopic crawler

crane is detached.

Thehookblockon theLTR

1220 remains reevedduring

the erectionprocess, so that it

canbequicklyused again for

handling components of the

wind turbines or otherwork.

Thenew erection concept

canbeused for all longboom

systems up to a lengthof 156

meterswith a12-meter fixed

jib.

■

12

ACT

NOVEMBER2014

Using the LTR 1220

as a derrick ballast

for erecting tall

wind power systems

on the LR1600/2.

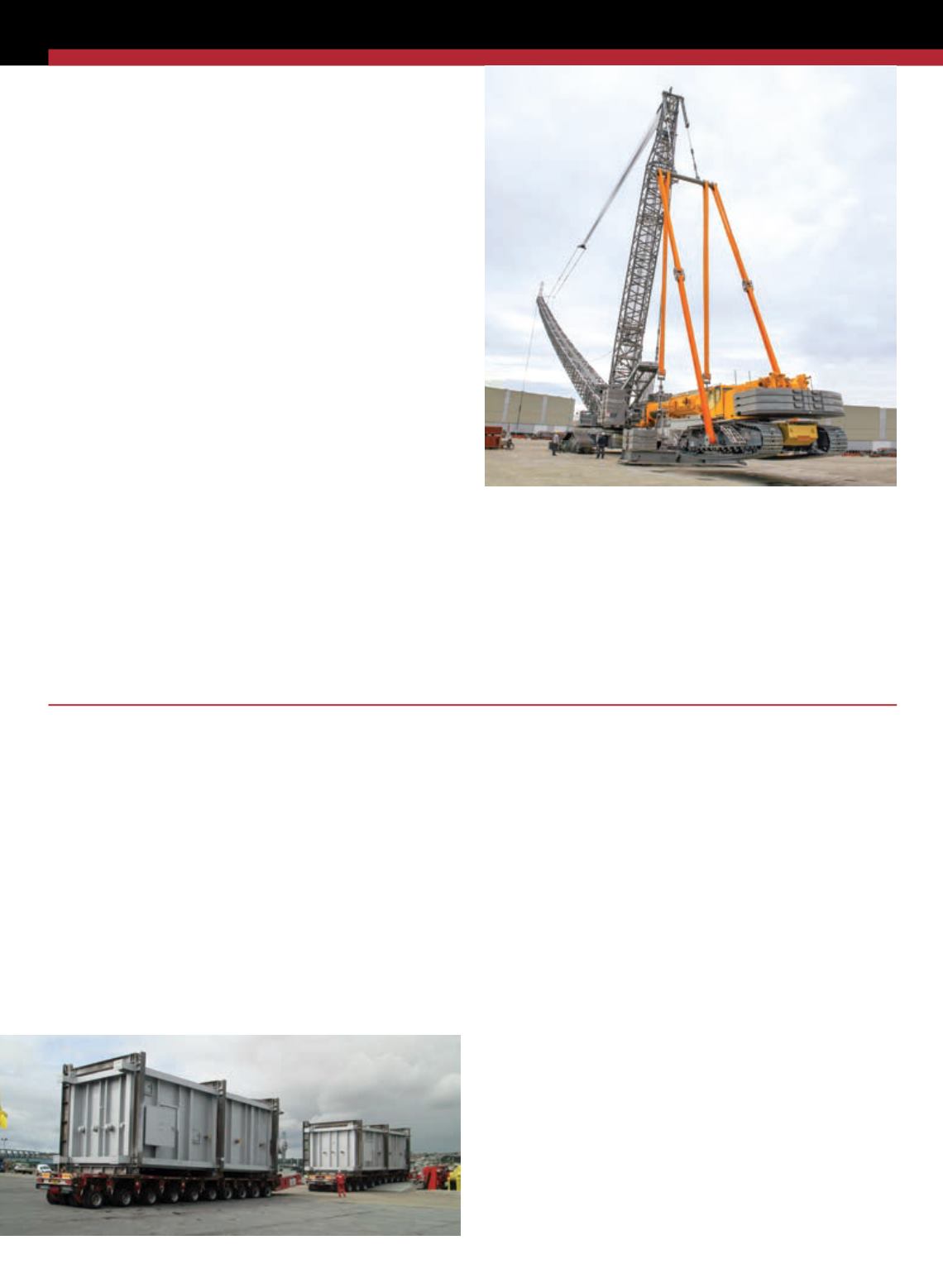

ALE completes 5,000mile journey

Adedicatedheavy-lift barge

then transferred theboiler

components to the refinery

jetty in twovoyagesusinga

combinationof SPMTs, SPTs

and conventional trailers. The

tidal restrictions at the refinery

jettyprovided tidalwindows

of less thananhour for arrival,

discharge anddeparture

of eachbarge. Thebarging

operationswere successfully

completedwithina fourday

period.

At the refinery eachboiler

componentwasdelivered in

sequenceunder the cranehook

for erectiononto foundation

andmechanical completion.

The route from jetty to

overseeingall aspectsof the

supply chain for the journey to

Pembroke.

The eightwasteheat

boiler components ranged

inweight,with the largest

weighing167 tons, andwere

transported from thevendor’s

facility inAbilene, Texas to

thePort ofHouston. The

boiler componentswere then

delivered inonevoyage and

receivedat PembrokeDockon

conventionalmodular trailers.

ALE, a leadingheavylift

company, has successfully

completeda turnkeyproject

onbehalf ofValero to

transport eight components

almost 5,000miles across the

AtlanticOcean, fromTexas to

Pembroke,UK.

For this turnkeyproject,

ALE supplieddedicated

and experiencedproject

management services,with

keypersonnel fromALE’s

HixonandHoustonoffices

the construction location

involvedheight restrictions

andby studying the route and

selectingappropriate trailers,

ALE ensured that eachboiler

componentwasdelivered

safely.

Tom Irvine, SeniorProject

Manager atALEwho

coordinated theproject,

explained thebenefitsof the

turnkeypackage: “Byoffering

the client a single-source

solution,wewere able to

utilize awealthof experience

fromour teamswithin the

UKandHoustonbranches to

plan,manage, coordinate and

select theoptimum solutions

at eachphaseof theproject.

Thismeant thatwe effectively

completed the transportation

of theboiler components

almost 5,000miles to the

Pembroke refinery ina timely

manner and incident-free.”

■

ALE performed project

management services to

move eight waste heat boiler

components from Abilene, TX to

Pembroke, UK.