11

NOVEMBER 2014

ACT

NEWS

First job for

Sarens’ Terex

BoomBooster

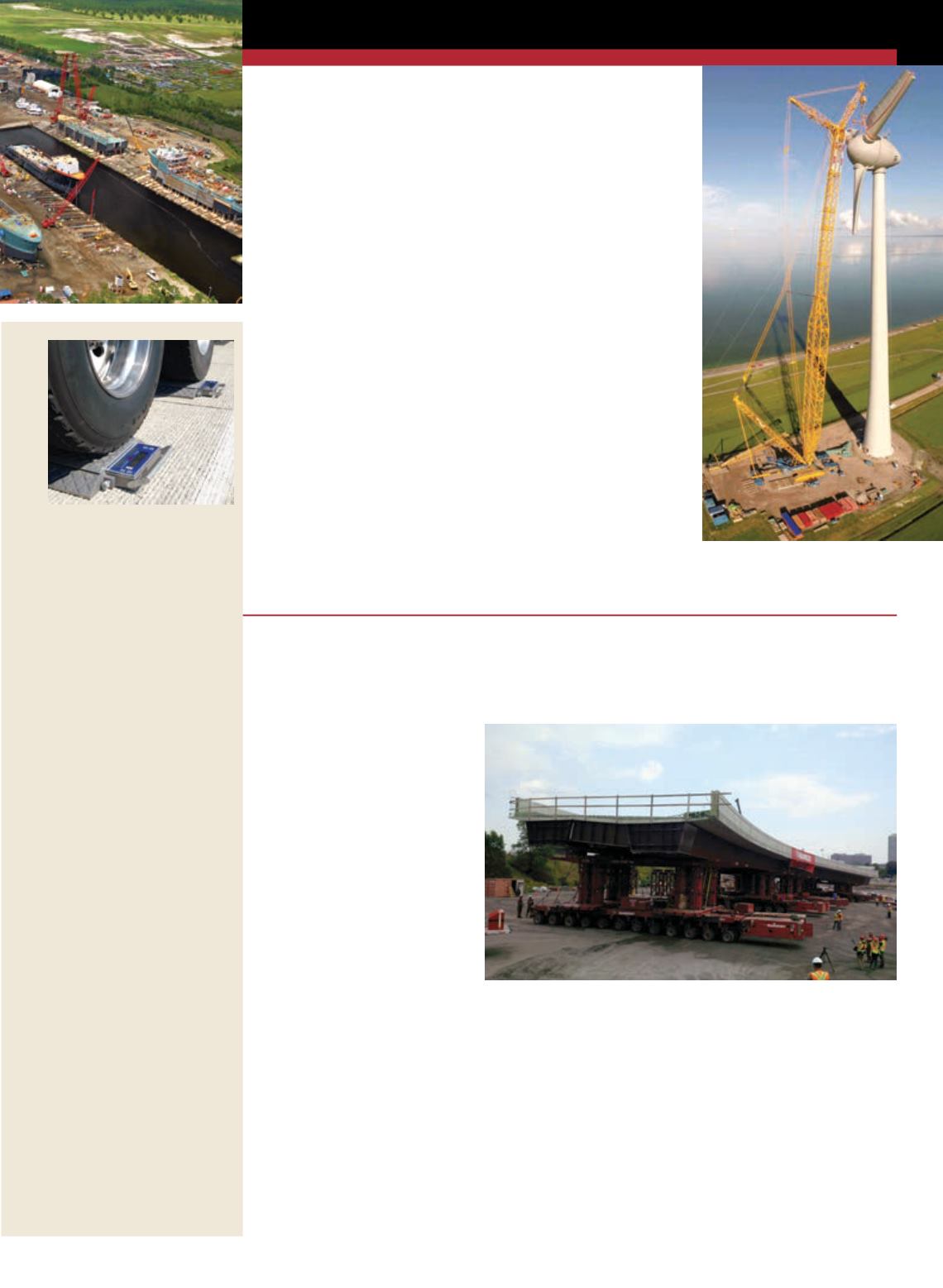

Belgium-basedSarensused

the first of its twonewTerex

BoomBoosters at awind

farm inNoordoostpolder, the

Netherlands.

TheBoomBooster is fitted

tooneof Sarens’ TerexCC

8800-1 latticeboom crawler

cranes,which is in the1,600

metric ton capacity class. It

replaces thebottompart of

the crawler’s boom, typically

increasing capacityby60

percent, themanufacturer

said.

TheCC8800-1withBoom

Booster is beingused to

install 38 largeEnerconwind

turbines. The turbineshave a

towerheight of 135meters and

a capacityof 7.5MW each, a

company spokesperson said.

TheBoomBooster ismade

of five inserts and two adapters

andmeasures 72meters

long. It is 10meterswide,

3.2metershigh andweighs

197metric tons. It ismadeof

singlegirders and lacingswith

pinned connections.

Sarens alsohas a second

CC8800-1 atworkwith a

BoomBooster. It isworking

at theSadaraProject in Jubail,

SaudiArabia. Tasks for the

crawler there include lifting

an85-meter tall column

whichweighs 800metric

tons.A second column lift is

scheduledbyyear-end.

■

The new Terex boom booster at

awind farm inNoordoostpolder,

theNetherlands.

PHOTO COURTESY OF KLAAS EISSENS

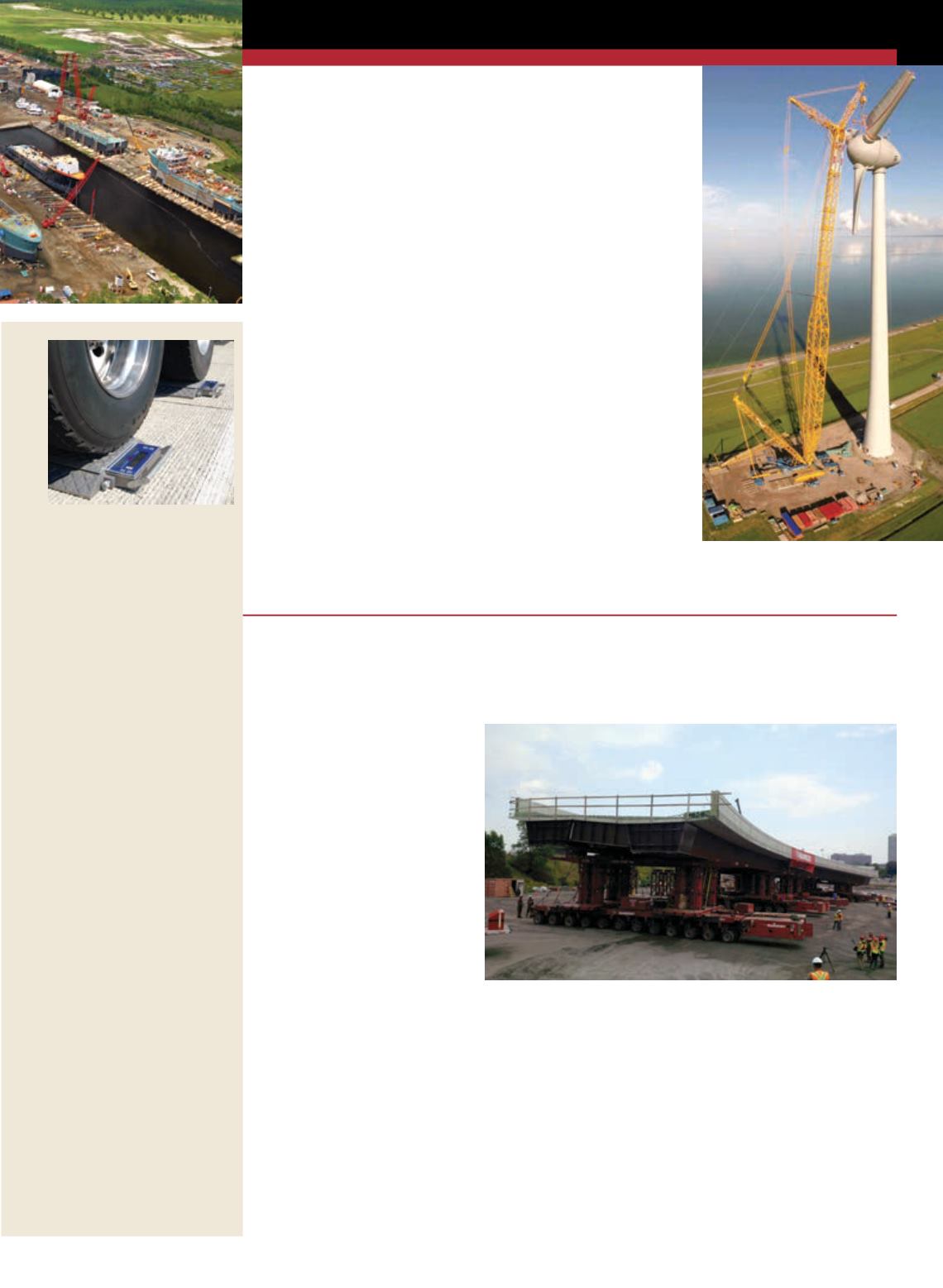

Mammoet replaces

huge bridge in Ottawa

Mammoet has replaced a

2,100metric tonbridgeover a

highway inOttawa,Ontario,

Canada, in a record timeof

2.5hours.

The replacement of the

85meter longLeesAvenue

Bridge inOttawa is the

heaviest one tobe carriedout

inOntario.Mammoetwas

commissionedbyTomlinson

Ltd. to carryout theproject.

Thebridgewas installed

using96-axles of self-

propelledmodular transporter

(SPMT), built anddesigned

byMammoet and specialized

trailermanufacturer

Scheuerle.

Challenges during the lift

werepresentedby the curved

designof thebridge. This

made it difficult to align the

transporters beneath the

bridge, a spokesperson said.

Themovewas also carried

out over a curved sectionof

themotorway, adding to the

difficulty.Despite this, the

bridgewas installed in two-

and-a-half hours, beating

the expected time frameof

between four and sixhours.

SteveCripps, professional

engineer anddirector at the

Rail ImplementationOffice

for theCityofOttawa, said,

“This heavy lift projectwas

well planned and executed

and an excellent example

of the teamwork required

todeliver theHighway417

component of theOLRT

Project. This projectwas

another first inNorth

America; theheaviest lift of

amulti-span structureover a

freeway todate.”

■

The curved bridgewas installed using a 96-axle self-propelled

modular transporter (SPMT) trailer, built and designed by

Mammoet and Scheuerle.

■

Intercomp has updated

its best-sellingwheel load

scalemodels. A solar charger

built into the scale indicator

allows the scales to operate

continuously without requiring

direct power charging. This

solar boostmakes Intercomp

scalesmore turnkey and

eliminates the need to recharge

batteries in-between uses.

This time-saving, solar

charging technology will be

standard on all PT300™,

PT300DW™, LP600™

and LP600-15T™Wheel

Load Scalesmoving forward.

Charging cableswill no

longer be included, but are

still available to be ordered if

desired.

HIGHLIGHTS

■

H&E Equipment Services,

Inc. (H&E) announced the

relocation of itsCorpusChristi,

TX operation to their newly-

constructed facility at 7809

IH-37AccessRoad, Corpus

Christi, TX. The new facility

is 20,000 square feet on 8

acres, with office space, parts

warehouse, a large yard area,

and an 8-bay repair shop that

includes two 5-ton overhead

cranes. The facility is capable of

repairing a variety of machines

from compact construction

equipment to large cranes, the

company said.