NEWS

12

ACT

AUGUST 2013

■

Sany Heavy Industry

Company President

Xiang Wenbo issued a

statement in response to

the investigation started

by the U.S. International

Trade Commission based on

a complaint by Manitowoc

Cranes LLC:

“Sany remains proud of its

industry-leading crane designs

and the heavy equipment

products and solutions we

provide for our customers. The

Sany SCC8500 crawler crane

was developed from start to

finish by Sany engineers, using

our own ideas and our own

technological innovation. We

categorically deny the claims

made by Manitowoc. Sany will

prevail on these claims before

the ITC and in the related U.S.

District Court action. The

institution of the investigation

by the ITC is simply the first

step in allowing Sany to confirm

that the success of its products

is the result of Sany’s superior

development and sales teams.”

■

Steil Kranarbeiten put its

new Terex Superlift 3800 to

work at a wind park at the

Gödenroth wind farm in the

Hunsrück mountain range in

Germany. The 650-metric-ton

capacity lattice boom crawler

was used to erect Enercon

E101 wind turbines. The crane

was rigged with 138 meters

of boom, a 12-meter luffing

jib and more than 305-metric

tons of counterweight. The

two tower sections for the

turbines weighed 56 and 58

metric tons. The 67-metric-ton

nacelle was lifted to a height of

135 meters.

HIGHLIGHTS

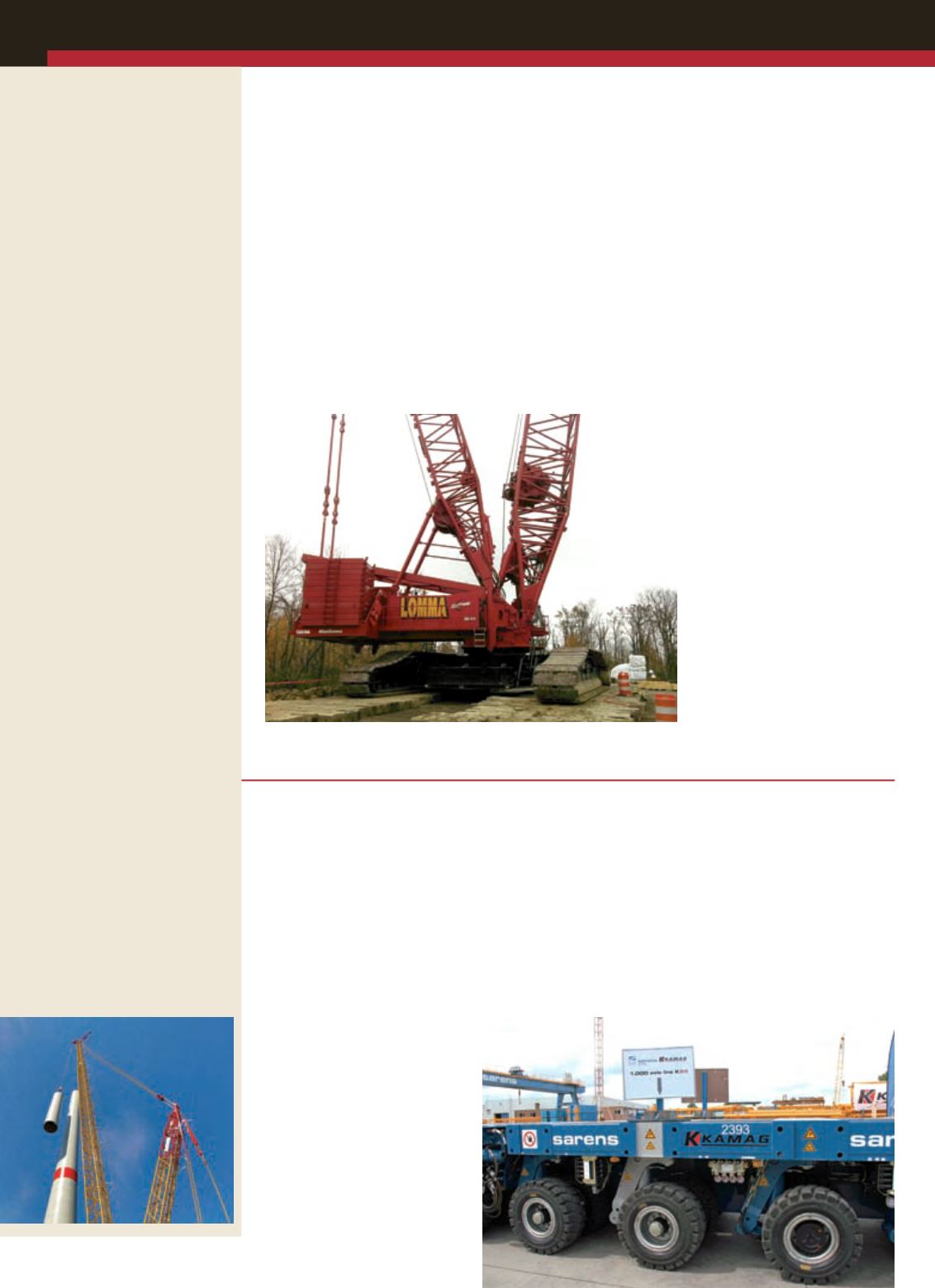

Crawlers perform

on Ice Mountain

Lomma Crane & Rigging

dispatched two crawlers,

a Manitowoc 18000 and a

Manitowoc 2250, to assist

with wind turbine erection

at Sandy Ridge Wind Farm

in Tyrone, PA. The cranes

erected 25 Gamesa G87 wind

turbines at the wind farm that

tower up to 330 feet.

While erecting wind

turbines is tough work,

this job got even more

complicated due to frigid

winter temperatures, powerful

winds and mounds of snow,

according to the company.

Steve Burkholder, Lomma’s

heavy lift manager at its

Pittsburg, Pa., location,

said the Manitowoc cranes

handled the job with ease.

“Despite the challenging

conditions, our Manitowoc

cranes operated smoothly the

entire time,” Burkholder said.

“The project went flawlessly.”

The installation of the

turbines was impressive

considering the Sandy Ridge

Wind Farm is located atop

Ice Mountain, in the middle

of the Allegheny Mountains.

The cranes battled subzero

temperatures, high winds,

hilly terrain and large

amounts of snow to complete

the project.

The northern portion of the

Appalachian Mountains has

some of the highest potential

for wind energy in the United

States.

Recently, Lomma added a

Boom Raising System to use

with its Manitowoc 16000

crawler crane, which allows

the crane to raise longer boom

lengths without the need of an

assist crane.

■

Lomma Crane & Rigging’s Manitowoc Model 18000 erects wind

turbines in Tyrone, PA.

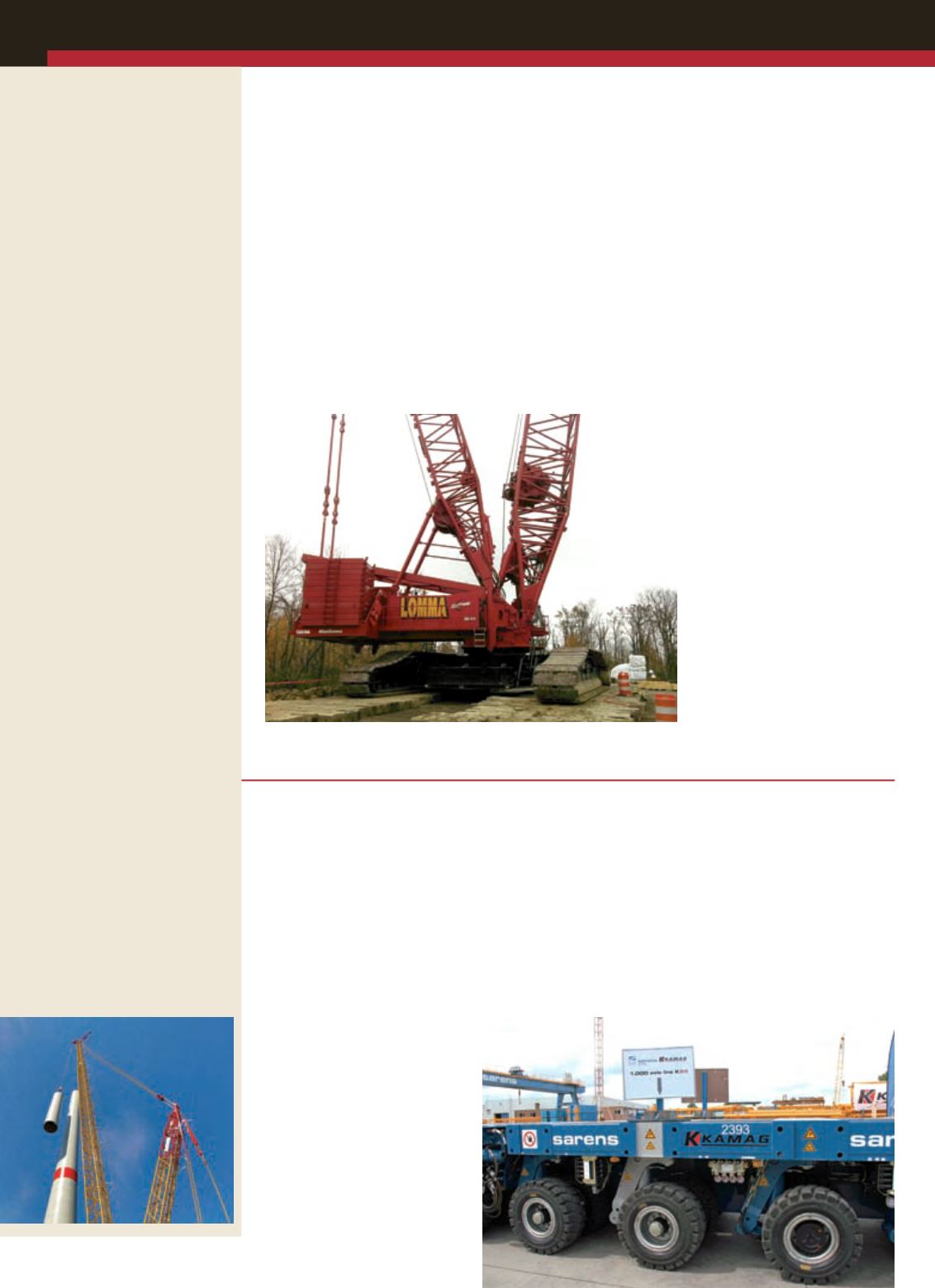

Kamag delivers 1,000th unit

The Sarens Group, based in

Wolvertem, Belgium, has

taken delivery of the 1,000th

unit of Kamag K24 axle line.

The transporter was handed

over to Sarens at an event in

June in Belgium.

“Having reliable vehicles

at our disposal is the most

important thing as we have

to rely 100 percent on our

equipment,” said Ludo Sarens,

president. “Those who want

to be at the forefront of our

business cannot afford to

have any breakdowns or

malfunctions; therefore, we

continue to strengthen our

fleet with Kamag modular

transporters.”

The K24 is 2,430 mm wide

and is suitable for worldwide

operation. It has a hydrostatic

drive for precise control and

electronic all-wheel steering.

The transporter can be used

for moving large industrial

installations, transportation

of complete bridges and

other large components, the

company said.

Kamag Transporttechnik

is part of the TII Group

in Germany that includes

specialized transport

equipment manufacturers

Scheuerle and Nicolas.

■

The Kamag K24 modular

transporter at Sarens, Belgium