18

MAY-JUNE 2014

d

&

ri

DEMOLITION

ATTACHMENTS

>

21

firms off guard. Export markets continue to

be added – new BAV dealers were signed last

year and more have already been signed this

year – but the stronger sterling is not helping.

Dealers in the USA and Russia were not as

busy as in previous years. Our most successful

new market last year was Norway.”

This demand has had a knock on effect

for BAV in terms of where its R&D effort

is concerned. Marcus went on: “Customer

requirements trump both R&D and stock

orders! At the present time, we’re running

with a minimum of 4 weeks work ahead.

On larger and more complex attachments,

it’s more like 5 to 6 weeks, so even building

stock of the existing range is not possible.

First priority are the dealer’s and customer’s

requirements, then we’re looking to augment

our own stock levels before we get the next

Working to a deadline

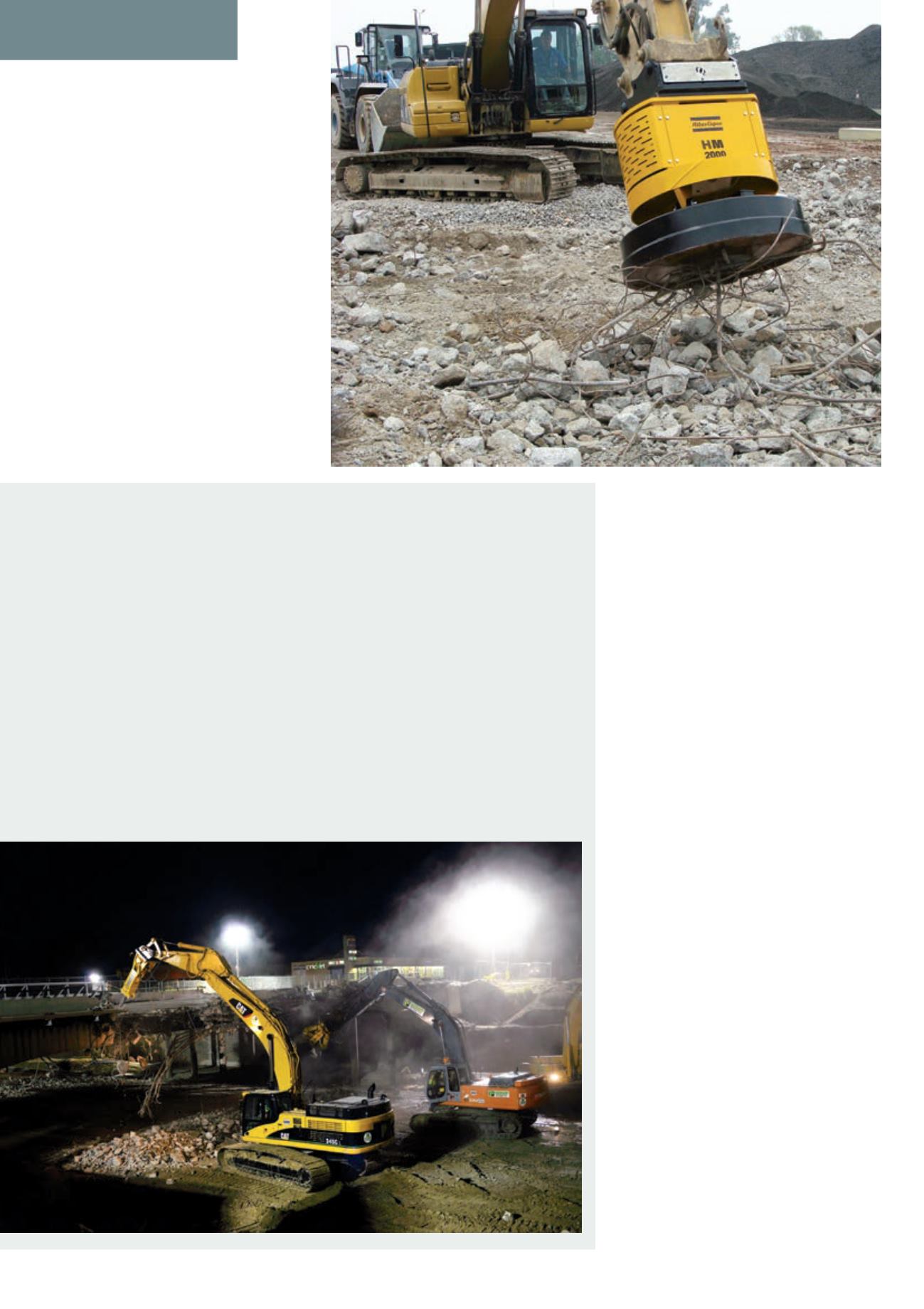

The Colorado Department of Transport opted for an Accelerated Bridge Construction

when carrying out improvements to Denver’s Pecos Street bridge at the Interstate 70

Interchange. The plan was to bring the bridge down and the road re-opened to traffic

at 7.00 am on the Saturday. Since the road could not be closed until 22.00 pm on the

Friday evening, that left just eight hours for the job to be completed. A replacement span

was constructed close to the site of the existing structure that was to be moved into

place once the existing span was removed.

To bring down the original bridge structure, Performance Equipment based in Erie,

Colorado, supplied four Atlas Copco breakers together with two Atlas Copco CC 3300

Combi Cutters. Before demolition of structure could begin however, the crews had to

construct a level path for the tracked carriers of the replacement span using earth

and steel plates, a task that took four hours, leaving just four for the demolition of the

reinforced concrete structure of the span.

Working from the centre out on both sides, each CC 3300 was paired with two

breakers, with the latter breaking up the concrete structure, with the former cutting the

steel reinforcement as it was exposed by each of the hammers. Despite just having four

hours to complete the job, the replacement span was moved into position according to

plan and the new Pecos Street bridge re-opened to traffic on schedule.

project off the CAD systems and into the

metal for testing. We have a complete new line

to add into the existing three line set-up of

jaw crushers, crusher buckets and screening

buckets, but for now it has to remain under

wraps."

Josef Martin GmbH told D&Ri that

it has seen a strong start to 2014 with a

definite upturn in market activity hinting,

the company says, that a full recovery is

under way. Sales throughout Europe and in

particular Austria, Germany and Switzerland

are on the increase and it views the rest of the

year with confidence. Martin also said that

it has recently made a demolition grapple

available for machines up to 28 tonnes in

weight.

DEVELOPING ATTACHMENTS

Allied Gator offers a patent-pending Serrated

Gator blade that is now available as an

option on new MT mobile shears and can

also be used with any of the 11 existing MT

shear models, irrespective of size, with no

modifications being required to the shear.

According to the company, the new blades

have a service life that is up to 50% longer

than traditional shear blades when processing

general scrap and up to 90% longer when used

to cut steel wire and cable. They can also be

used effectively to process difficult materials

such as stainless steel and thin sheeting.

Allied-Gator sales and marketing manager

Mike Ramun said: “The serrations of the MT’s

new blades are designed to progressively pass

through material like a saw blade rather than

forcing the shear to chop through a large mass

of material like an axe.

This new blade design does not rely solely

on sharp shear blade edges to achieve the

cut. Instead of a snipping effect, these blades

generate a tearing action. This allows the MT

shear to grip and tear scrap materials, which

is a far more efficient cutting method than

the traditional ‘scissoring effect’ utilised by all

other mobile shear blades.”

As the shear jaws close on structural steel,

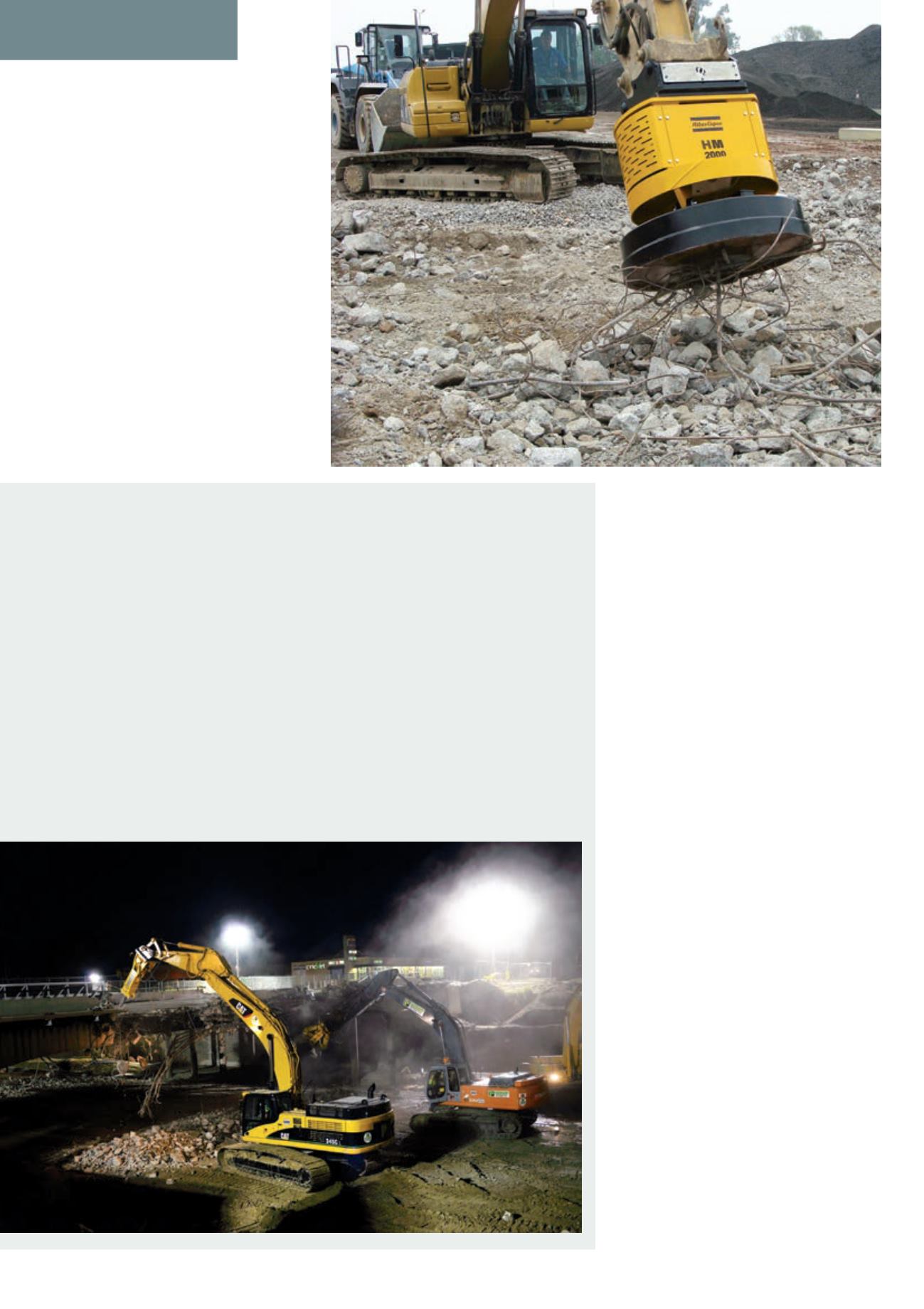

Atlas Copco has introduced two new

Hydro Magnets that are aimed at the

recycling, scrap and demolition sectors

Staker Parson demolition crews had just eight

hours to remove a bridge at Denver’s Pecos

Street and Interstate 70 Interchange