international

construction

june 2014

ROADBUILDING

36

Economy drive

pavers in Russia is particularly exciting. Obviously the Russian

Federation is an extremely important market in terms of road

machinery and I believe this launch shows our commitment to

road building customers across the Federation.”

The C-Series models being launched in Russia feature a new

range of Stage IIIA-compliant Volvo engines designed to offer

improved fuel efficiency evenwhen run on diesel with a higher

sulphur content, as currently found in thatmarket.

Mr Fitch said, “The installation of Volvo engines means

customers can now rely on a single partner to support their

paving investment.

Meanwhile, as reported in the Equipment pages of theMarch

issue of

iC

, Atlas Copco has launched a new range of rollers,

pavers and feeders this year designed not only to be better than

previousmodels, but also safe and environmentally friendly.

Agoodexample is thecompany’snewDynapacCG2300 roller,

whichhas steeringdrums, rather than the central articulationof

theDynapacCC twin drummachines.

A key feature is the ECOMode as standard, which is said

to reduce fuel consumption by more than -15% and noise is

also kept down through the use of a hydraulically-driven,

temperature-guided cooling fan, which only operates when

necessary.

Formore details of this andother new roadbuildingmachines

fromAtlas Copco, see theMarch issue of

iC

.

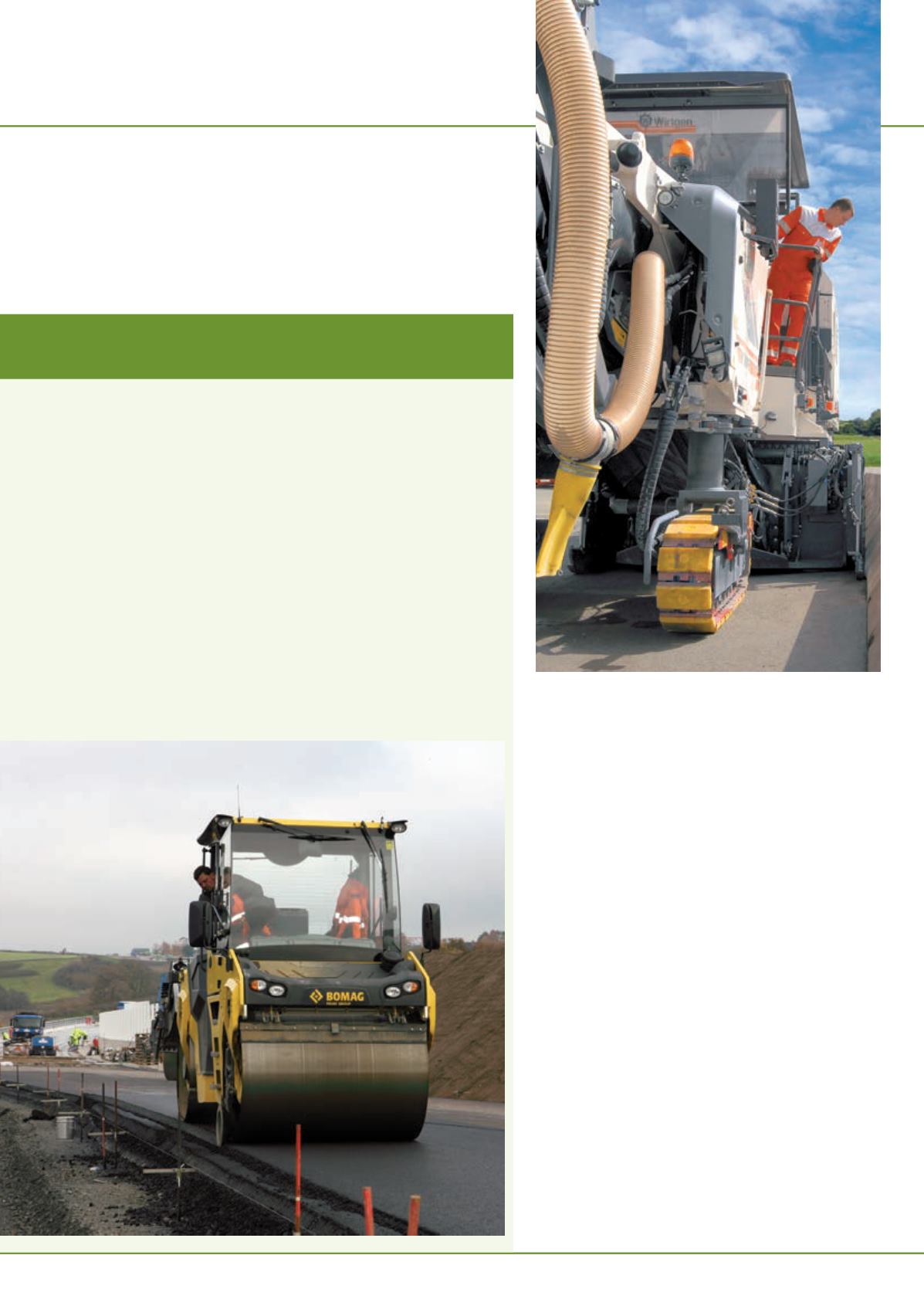

In the cold milling sector meanwhile, Wirtgen has a new

version of its largeW 200 planer, which has a drum that can be

offset 400mm to the left or right.The company says this feature

of theW 200Hi makes life easier on confined sites, as there is

less need to manoeuvre the whole machine (which weighs 30

tonnes) and also allows contractors towork right up to the edge

of obstructions like barriers and kerb stones.

The edge protector can be raised by 420 mm on both sides

so that the machine can work flush with the edge even at large

working depths.

In action

New technology in the sector is one thing, but as far as

contractors are concerned, it has to have a benefit and a

pay-back.

Tangential oscillation

Compaction in the cold on keymotorway

T

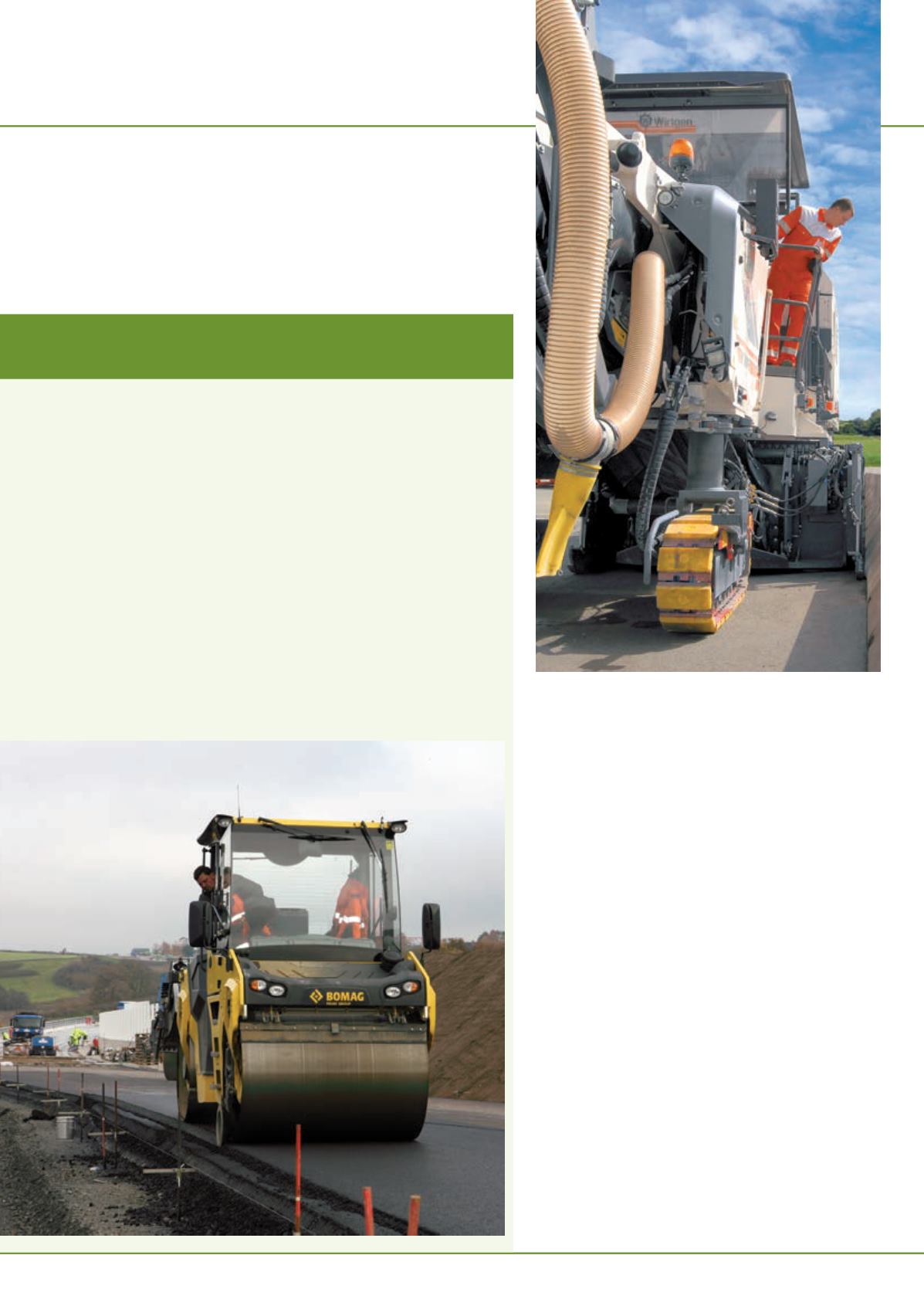

heB 327, Germany’s Hunsrückhöhenstraße connecting northSaarland, Hunsrück (Hahn

airport) andKoblenz, often sees heavy traffic leading to long tailbacks, especially on the

Kastellaun section in theHunsrück.

In the spring of 2012, a bypass project was started. HermannKirchner Bauunternehmung,

based inBadHersfeld, was awarded the contract for the sections before and after the

Trimmbachtal Bridge, and it used the latest generationBomag tandem roller with tangential

oscillation to compact the asphalt.

A bearing coursewith a depth of 140mmwas laid first. Bomag said that on normal days

thiswas not a problem, but because asphalt cools down and goes hard fast in coldNovember

weather andwind, laying and compaction had to be performed quicker in autumn andwinter

months.

Also, on theB 327, connecting sections had to be traversedwhich required accurate

steering and a good overview. Bomag said that working the 140mm deep bearing course

presented no difficulty to theBW 161ADO-5with its 10 tonne operatingweight and 1.68m

wide roller.

Next was connecting sections and processing a longitudinal joint. Usually, rolling is static to

beginwith and subsequentlywith vibration, but Bomag said it was different with this roller.

The tangential oscillation in the rear drum generates horizontally directed shearing forces.

It said this allowed gentle and efficient joint compaction–without the need for vibration in

colder weather.

TheWirtgen

W 200 Hi can

work flushwith

kerbstones or

concrete barriers

>