41

june 2014

international

construction

ROADBUILDING

Economy drive

An example of this has been seen in Saudi Arabia, where

general contractor Al Mabani is laying much of the asphalt on

the expansion of the country’s biggest airport, King Abdulaziz

International Airport (KAIA) near Jeddah.

Thefirst phaseof the expansion is due for completion this year,

with Saudi Binladin Group the main contractor. Al Mabani’s

work started on the aprons and taxiways and then moved on

to the runways, where it used twoCat AP1055E asphalt pavers

withAS3301C screeds.The pavers placed five layers of asphalt,

totalling 420 mm - two layers of polymer modified mix,

followed by three layers designed using theMarshall method.

Pavers worked at a width of 6m, and typicallymoved at 5m

perminute.Theywere the first pavers in the country to feature

Cat’s Mobil-Trac System (MTS) undercarriage, which features

fully-bogied support rollers that maintain contact with the

surface regardless of irregularities. This means the asphalt mat

that gets laid is smooth, with anydips andbumps in the ground

not being translated into dips and bumps in the final surface.

An Al Mabani project manager stated there will be fewer

final mat level issues due to debris on the paving surface. “We

clear all debris to the extent possible, and theMTS is an extra

assurance,” he said.

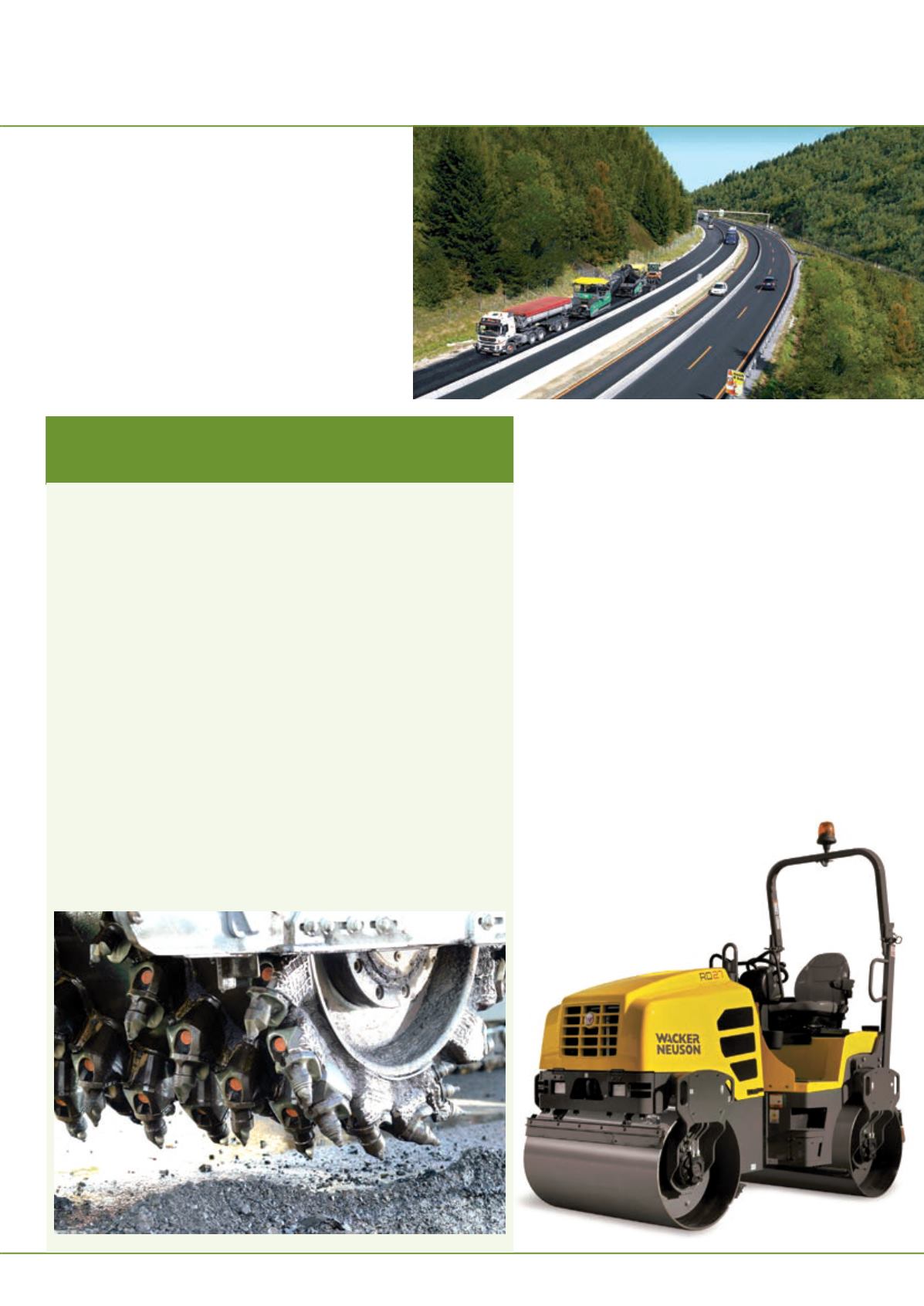

Meanwhile in Austria, a consortium comprising Granit and

Swietelskyhad tocontendwithall theusualhazardsof live traffic

as well as up to 1 km between access points while resurfacing a

section of the A2motorway near Schäffern.

The access problemmeant it would be difficult to ensure an

uninterrupted supplyof hot asphalt to the paver, aVögele Super

1900-2, using conventional techniques. To get round this, the

contractors opted for aVögeleMT3000-2Offset Power Feeder

with pivoting conveyor.

The feeder received the mix from trucks and continuously

transferred it to the paver without physical

contact, while the lorries navigated the

site. With the capacity to accommodate

an entire 25 tonne truck load of asphalt,

Diamondmilling picks

Element Sixmilling tool lasts 40 times longer

W

hen synthetic diamondmanufacturer Element Six says it is in the ‘supermaterials’

business, it is not being immodest. The company’sD-Power diamond tipped picks

formilling applications have been shown to last an incredible 40 times longer

than traditional tungsten carbide products. In an early field test it found a set of traditional

milling drum picks had to be changed after 4.5 km of road surfacewas removed, whereas

itsD-Power productswere still going after 180 km.

There are some obvious advantages to this aswell asmore subtle benefits. The first is

that downtime ismassively reduced as the long life of the picksmeans it is possible to

operate continuously. There is also a sustainability benefit, as every change of picksmeans

discarding several hundred kg of wastemetal in the form of the holders and structures

around the cutting tip.

But better wear characteristics have other benefits too. Continually sharp picks can save

5% to 15% in fuel costs according to Element Six, there is a better andmore consistent

finish to themilled road, and vibration is reduced, which is good for the operator and

machine alike.

But of course diamond is an expensivematerial, as SimonHardy, businessmanager for

Element Six’s road business said, “As a rule of thumb they are 40 times the price.” Sowhile

there is not necessarily any saving in consumable costs compared to traditional picks, Mr

Hardy added, “There are lots of other benefits in fuel efficiency, less downtime and better

performance.”

TheD-power picks are available through Element Six’s sales network and the standard

product is compatiblewithWirtgen’smilling drums andmounting system. “We can produce

them for othermachine types, but at themoment we are very heavily focussed onWirtgen

machines because they are a dominant presence,” saidMr Hardy.

Contractors Granit and Swietelsky used

a VögeleMT 3000-2 feeder to ensure a

continuous flow of asphalt to the Super

1900-2 paver on the resurfacing of a

section of the A2 in Austria.

Wacker Neuson’s newRD27, features a

detailed control panel and the choice of

low and high compaction force.