29

june 2014

international

construction

EXCAVATORS

Digging deep

A pilot lock handle installed on the handrail box prevents

unexpected movement as it interlocks the machine ignition

system. Liugong has also designed its operating handles to be

soft and flexible to avoid operator fatigue.

Fuel efficiency

For contractors looking to maximise on fuel efficiency, hybrid

machines couldbe the answerwith technology that captures and

reuses waste energy.

Hybrid excavators first entered the market back in 2008 and

today the technology has been refined to offer up to +30% fuel

savings compared to standardmachines.

Caterpillar’s new 336FH hybridwill soon be available with a

Tier 4 Final Cat C9.3 ACERT engine. The machine is one of

themost efficient on themarket as it offers an automatic engine

speed control, which lowers engine rpm during no-load/light-

load conditions. It also has an engine idle shutdown system and

an eco mode. The engine also runs on fuels containing up to

20% bio diesel (B20).

Increasing efficiency is the Cat Swing Energy Recovery (SER)

valve, which captures kinetic energy from the 336F H’s swing

deceleration, storing it for reuse in hydraulic accumulators.

Komatsu is an established hybrid manufacturer, having just

released its third generation hybrid model to the European

market. The new HB215LC-2 hybrid hydraulic excavator has

an operating weight of 22.6 tonnes and a bucket capacity of

1.68m³.

According to Komatsu, the new excavator boasts enhanced

Volvos dig Dubai Canal

Nine excavators areworking on installing irrigation lines

D

ubai-basedDetechContracting has been using nine Volvo excavators for

infrastructureworks on theDubai Creek Extension Project, whichwill create a canal

waterway linking theDubai Creek to the ArabianGulf.

Detech isworking on installing sewerage, drainage and irrigation lines for the project, and

will install a 15 km pipeline.

Excavating the area is complicated, as the ground has a highwater table and the soil

conditions are changeable from hard rock to soft clay.Weather conditions such as sand

storms and temperatures of up to 50°C also present challenges.

The company is using nine Volvo excavators in total, including two EC240BLCmodels,

two EC290BLC, an EC300BLC, EC210BLC, EC360BLC and EC380BLC. It also has two

Volvo L120G-Serieswheeled loaders and two VolvoBL61 backhoe loaders. The company

is using thewheeled loaders for backfillingwork, and backhoe loaders for cabling and duct

installationwork.

Themachines have clocked up about 10,000 hours each so far, working six days aweek

for 10 hours a day, but will sometimeswork two shiftswithin 20 hours. The project began in

2013 andwill take three years to complete.

“We chose Volvomachines because they use less fuel compared to other brands and the

company has good financing options,” saidAytac Akturk,managing partner and general

manager at Detech. “Themachines feature easy-to-use controls, the cabins are very

comfortable and the dealership responds quickly to our requirements.”

TheDubai Creek Extension

Project will create a new

water passage fromBusiness

Bay to JumeirahBeach,

cutting across Sheikh Zayed

Road to Jumeirah.When

completed, the canal will run

for 3 km. Its construction

involves several major

enablingworks, such as the

construction of twomulti-

span eight-lane highway

bridges.

G

erman contractor Schrode has unlocked savings of some

€

3,000 (US$4,100) per year

by switching the hydraulic oil used in its 24 tonne excavator.

The excavator experiences high utilisation rates, and company CEORainer Schrode

was keen to seewhether a high technology oil could help cut the fuel bill. He opted for OEM-

Approved Equivis HE hydraulic fluid from Total, which features the company’s ‘Dynavis’

technology and carried out an eight-week trial with startling results

After replacing all 230 litres of conventional hydraulic fluidwith aDynavis-formulated

refill, andworking at full tilt, the fuel consumption of theNewHolland-built excavator

dropped from 22.2 litres per hour to 16.7 litres – a 25% reduction in fuel cost.

When operated in heavy-dutymode, the fuel savings for theNewHolland excavator came

to about

€

300 (US$410) per week.With less rigorous duty, and an average 40weeks of

operation per year, fuel savingswere estimated to result in an annual savings of some

€

6,000

(US$8,200).

Oil change

Dynavis hydraulic fluid delivers significant fuel savings

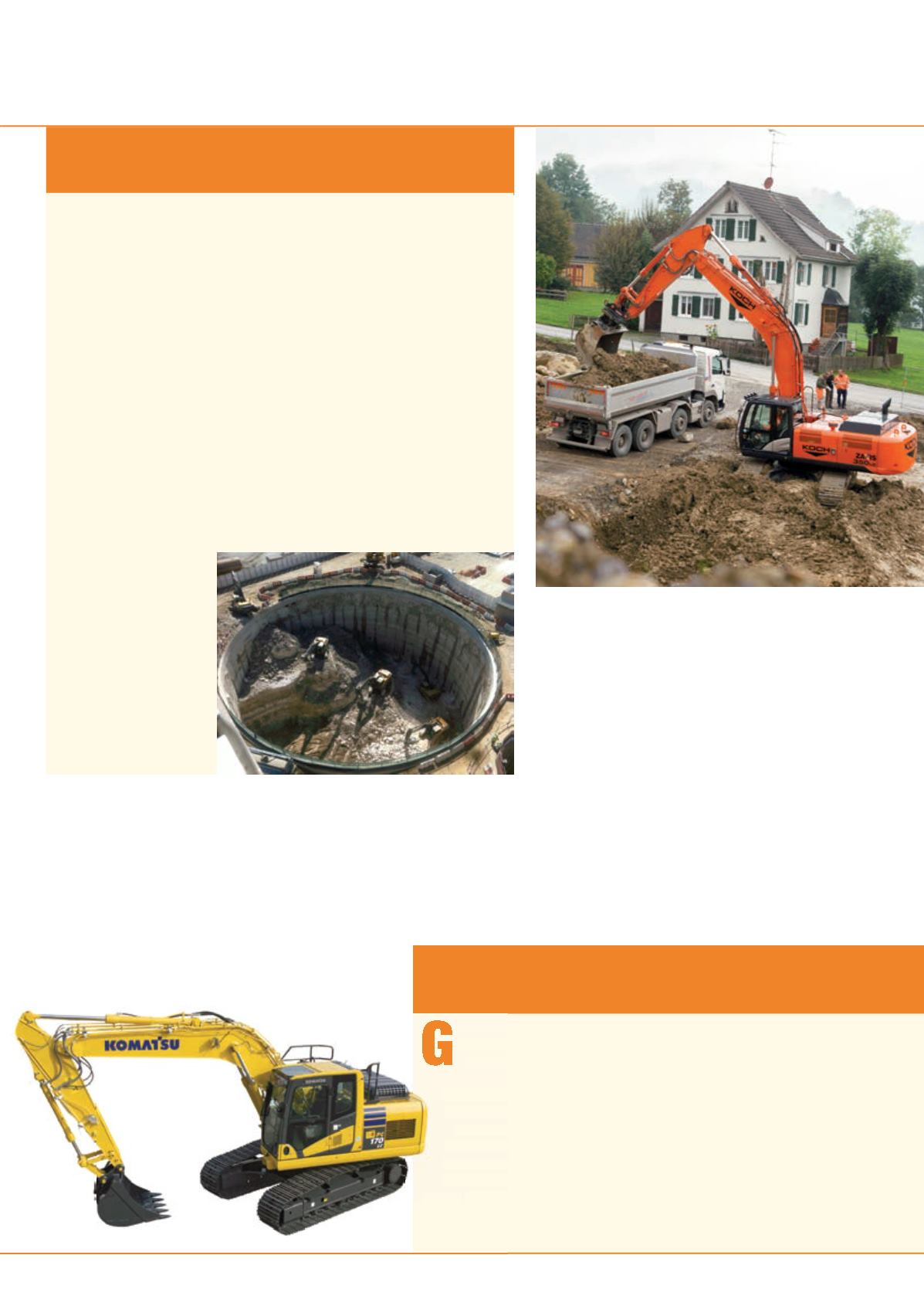

Swiss contractor Koch AG put its newHitachi ZX350LC-5 o

work on a housing development.

Komatsu’s new

PC170LC-10

offers up to

15%more

lift.