engineering input.”

For turbine installation projects, Sea

Power stabilises itself using the four jack-

up legs. The crane then lifts the nacelle

at a radius of 16 m. “At this stage the

superlift mast is not connected to the

vessel,” a company spokesperson says.

“The crane then slews 90 degrees along the

longitudinal axis of the vessel, connects the

superlift and elevates the nacelle into its

assembly position at 22 metres.”

Future trends

The trend for increasing sizes of offshore

wind turbines could however change the

way wind turbines are installed and the

need for high lifting capacity cranes could

be phased out. A spokesperson from

Liebherr explains more, “Wind turbine

companies are looking for alternative ways

to install wind turbines, other than cranes.

This is because the turbines are getting

bigger and more difficult to be

installed offshore.”

Other areas that are due for change

in the offshore heavy sector are

platform modification and platform

decommissioning projects, which have

been growing in the last few years.

■

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

OCTOBER 2013

59

OFFSHORE LIFTING

>

DEEP SEA INSTALLATION

Heavy lift shipping and offshore

transportation and installation contractor,

Jumbo, has been awarded a contract by

Malaysian pipelay contractor, Sigur Ros to

oversee the transportation and installation

of 126 gravity anchor spreads. The spreads

will be installed 1,400 m under water

using two 900 tonne mast cranes on the

vessel Fairplayer.

The spreads are made up of a

230 tonne gravity anchor, tether wire and

subsea buoys, which will be used to moor a

pipeline, a company spokesperson said. The

pipeline will have a diameter of

1,600 mm and will run 80 km from Turkey

to Northern Cyprus and will floated at a

depth of approximately 250 m.

For the project, the anchor spreads

will be lowered into position using the

Fairplayer’s mast cranes and its DP2

system, which will be used to maintain the

vessel’s position. “One of the cranes will

oversee the deployment of the buoy and

tensioning of the tether wire, whilst the

other will lower the anchor,” a company

spokesperson said. The project is due to

start the end 2013.

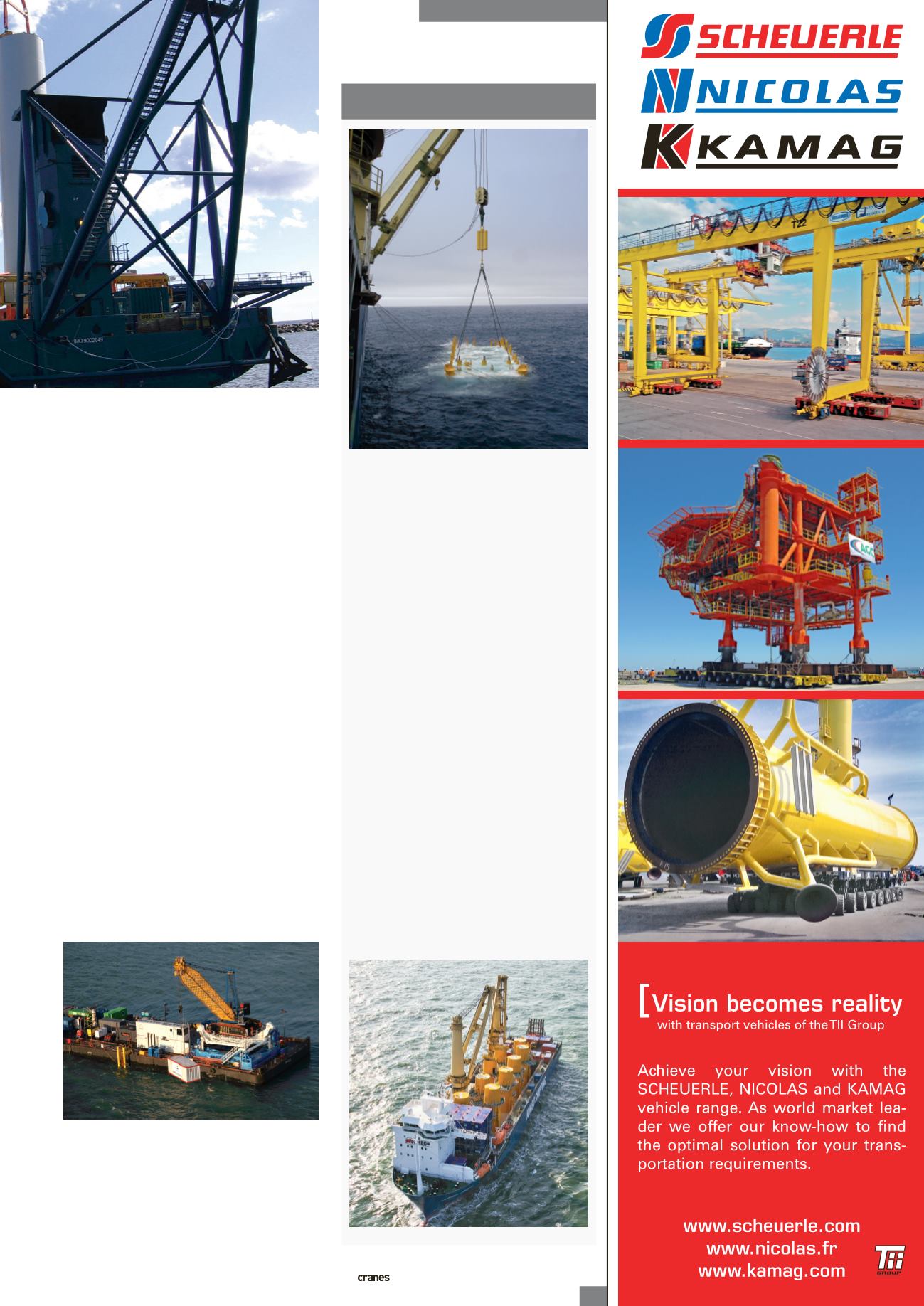

A 900 tonne

mast crane

at work on

Fairplayer

The Fairplayer

is fitted with

two 900 tonne

mast cranes

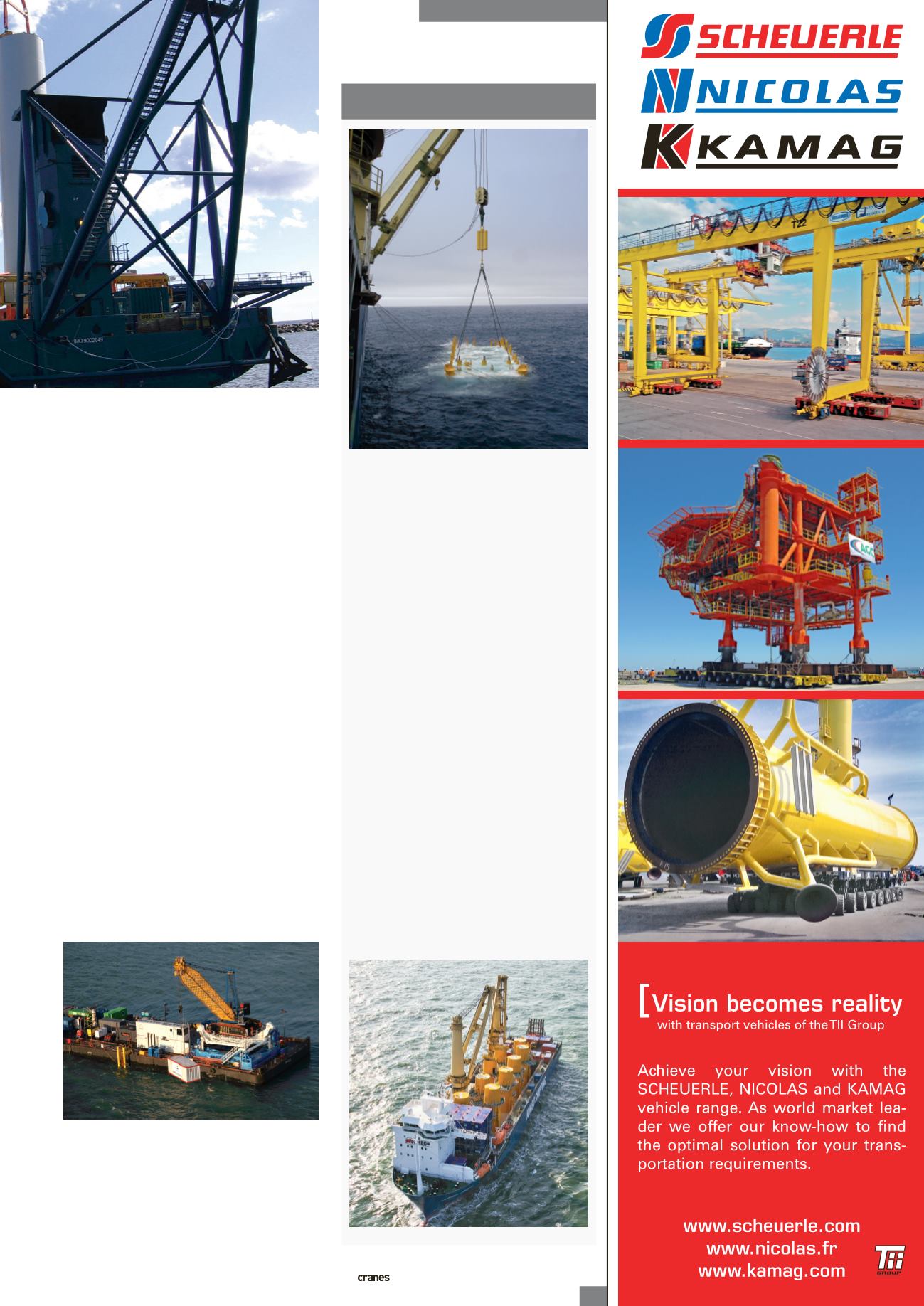

A T700 Barge Master heave compensation

system rented by Boskalis. The smaller new

Barge Master T40 system (see box story on

motion compensated cranes) is based on the

Barge Master T700. The system compensates

roll, pitch and heave to keep a vessel mounted

crane stable when in operation at sea.