57

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

OCTOBER 2013

>

Changing tides

Manufacturers and offshore

lifting equipment providers

are expanding their ranges

of bigger lifting equipment

to keep up with demands

for a new generation of

offshore projects.

LAURA HATTON reports

T

rends in the offshore industry are

changing and manufacturers and

service providers are experiencing a

demand for bigger equipment for offshore

use. Part of this is due to the increasing

size in offshore platforms and tension-leg

platforms (TLP) and deeper depths in

subsea exploration.

“There is a clear trend that TLP’s are

getting bigger,” a spokesperson from

heavy lift and transport company ALE

explains, “We are also seeing the size of the

transformer platforms increasing. As

a result the equipment used for the load

outs and installations demands an

increase in capacity.”

To accommodate the demand in the

offshore industry ALE has added a number

of high capacity strand jacks to its fleet.

“This year alone we have purchased five

1,250 tonne Strand Jacks, 58 900 tonne

Strand Jacks and a further 18 500 tonne

Strand Jacks,” an ALE spokesperson says.

“The Jacks have been used in different

offshore locations including the North Sea

and will be used on future projects in the

coming months.”

An example of an offshore project from

ALE where the Mega Jack system was

deployed was for the jack up the 44,000

tonne topside of the Arkutun Dagi. For the

project the topside was raised to a height of

22 metres. “With such versatility the Mega

Jack will be used on future offshore projects

such as mechanical floatovers and other

applications,” a company spokesperson

adds. (See

IC

June issue on page 25 for

more information on this project.)

Crane manufacturer Liebherr has

also accommodated customer demands

for increased lifting capacities for the

offshore sector. A result of this has

been the production of the CAL 45000

heavy offshore crane. The crane was

manufactured at Liebherr-Werk Nenzing

and it has a lifting capacity of 1,200 tonnes

at a working radius of 27.5 metres. The

crane is fitted with a 108 m boom and can

achieve a lifting height of more than 120 m

above deck.

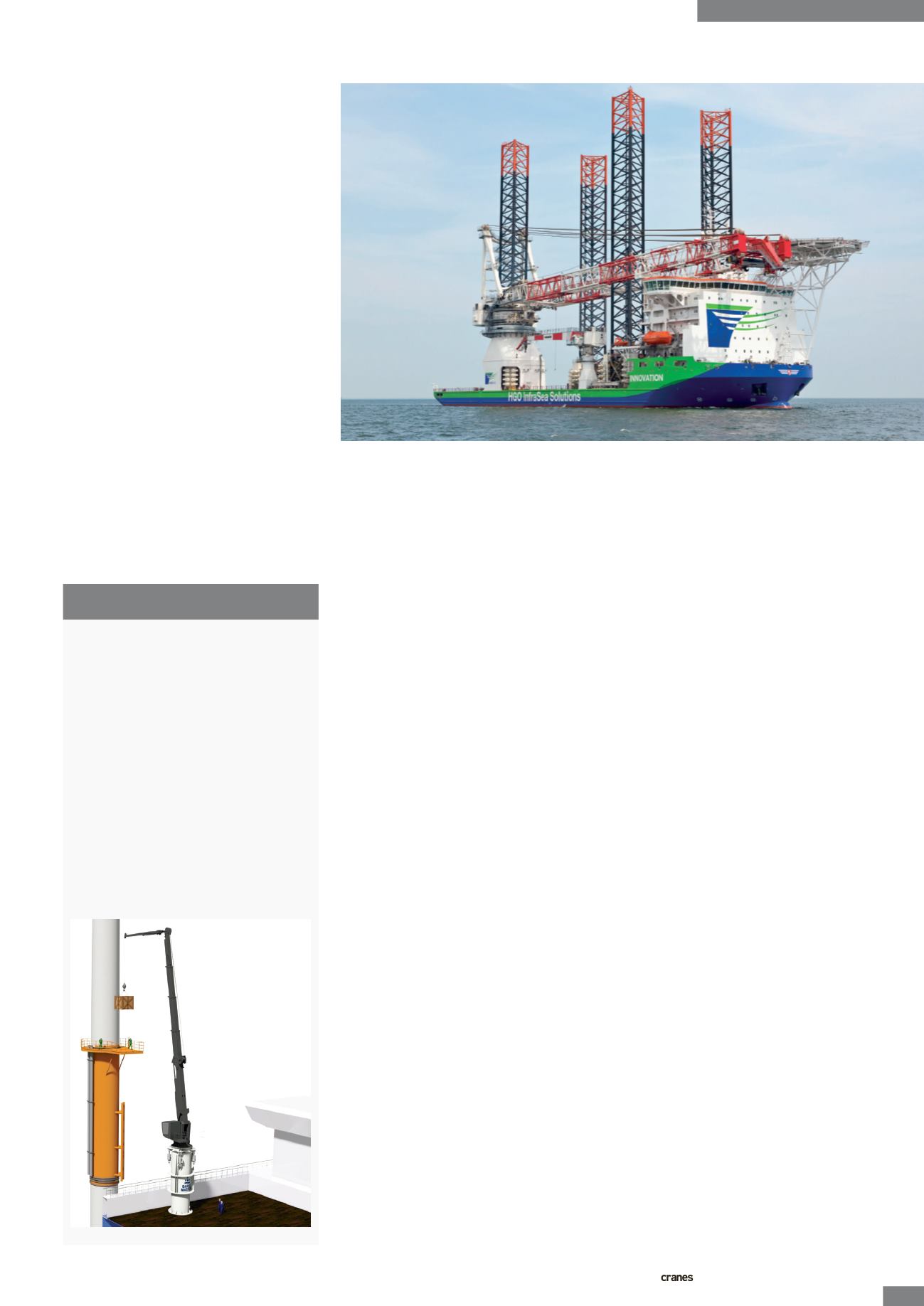

“The crane is designed as a ‘crane

around the leg’ (CAL). This means it is able

to rotate 360 degrees around one of the four

jack-up legs of the vessel,” a spokesperson

from Liebherr says. “It requires

a small obstruction area of only 12 metres

and has a special twin-boom design, which

means that two booms run parallel to each

other at a distance of 14 metres. This allows

the boom to be parked over one of the

vessel’s front legs.”

The slewing ring of the heavy lift crane

has an outer diameter of 13 m. It has a

4,000 kW electro-hydraulic drive and the

Liebherr Litronic system. A CAL 45000

is currently installed on the

Vidar

, an

installation vessel belonging to Hochtief

Solutions, and is due to be used for the

installation of offshore wind power stations.

Also new from Liebherr is the

RL-K 7500 subsea crane. A spokesperson

from Liebherr explains more, “In search

of new natural resources our clients are

exploring and developing offshore fields

MOTION

COMPENSATED CRANES

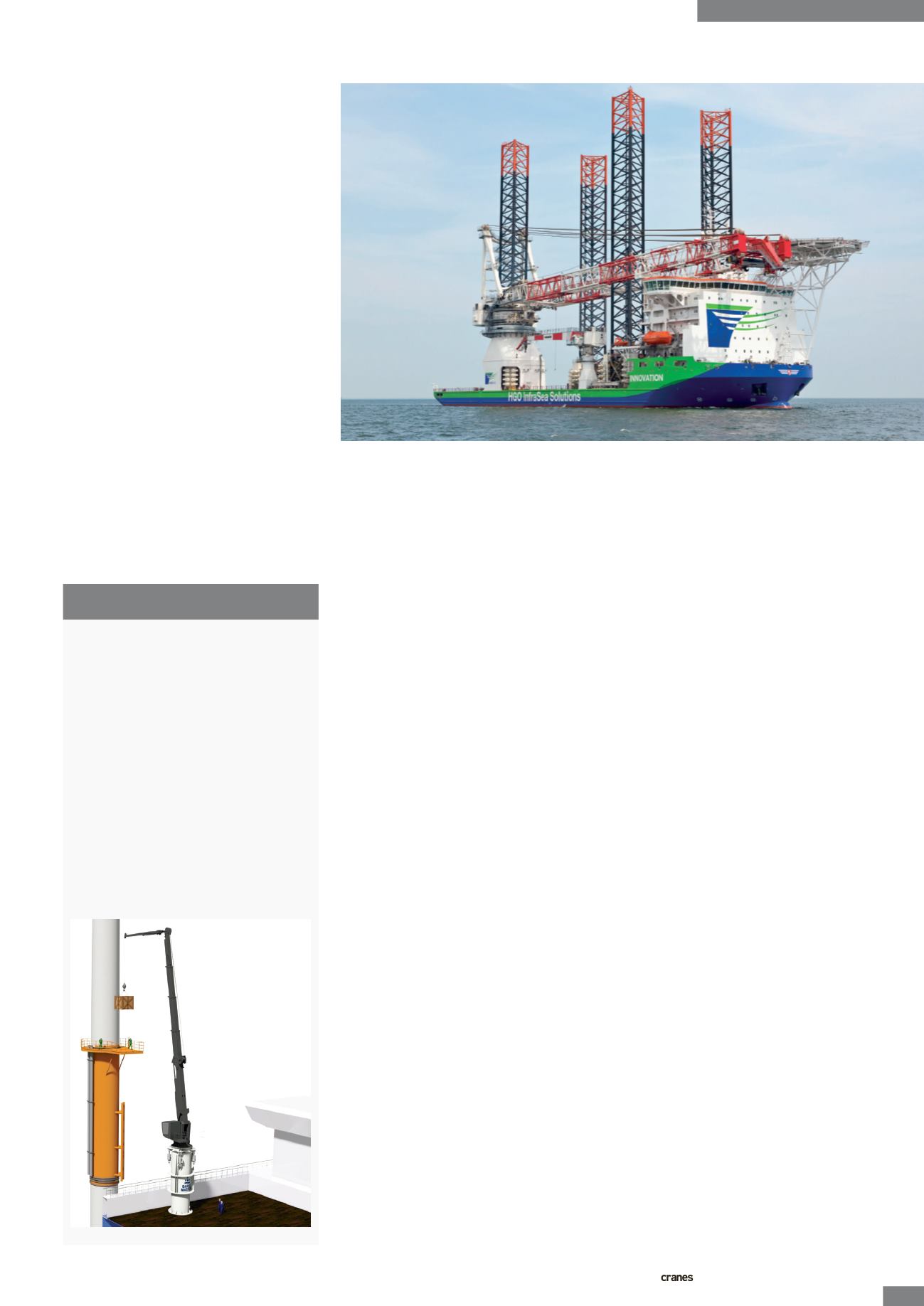

Barge Master, a manufacturer of wave

compensation platforms, has been

commissioned to develop a new model

for a crane on a Walk-to-Work ship built

by shipbuilder Niestern Sander,

the Netherlands.

The new wave compensation model, the

Barge Master T40, is being developed for

crane rental company Wagenborg. The T40

can be fitted with an offshore knuckle boom

or a telescopic boom crane with a capacity

of 15 tonnes, the manufacturer said. It is

designed to help cranes service offshore

wind turbines or unmanned oil rigs. The T40

has been developed with Bosch Rexroth and

will be ready in the first quarter of 2015.

OFFSHORE LIFTING

A Liebherr CAL 64000

heavy lift offshore crane