THE KNOWLEDGE

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

NOVEMBER 2013

38

was turned upside down (now the ram

protrudes from the bottom), a load

bearing platform was constructed around

the bottom of the jack and the climbing

jack was born.

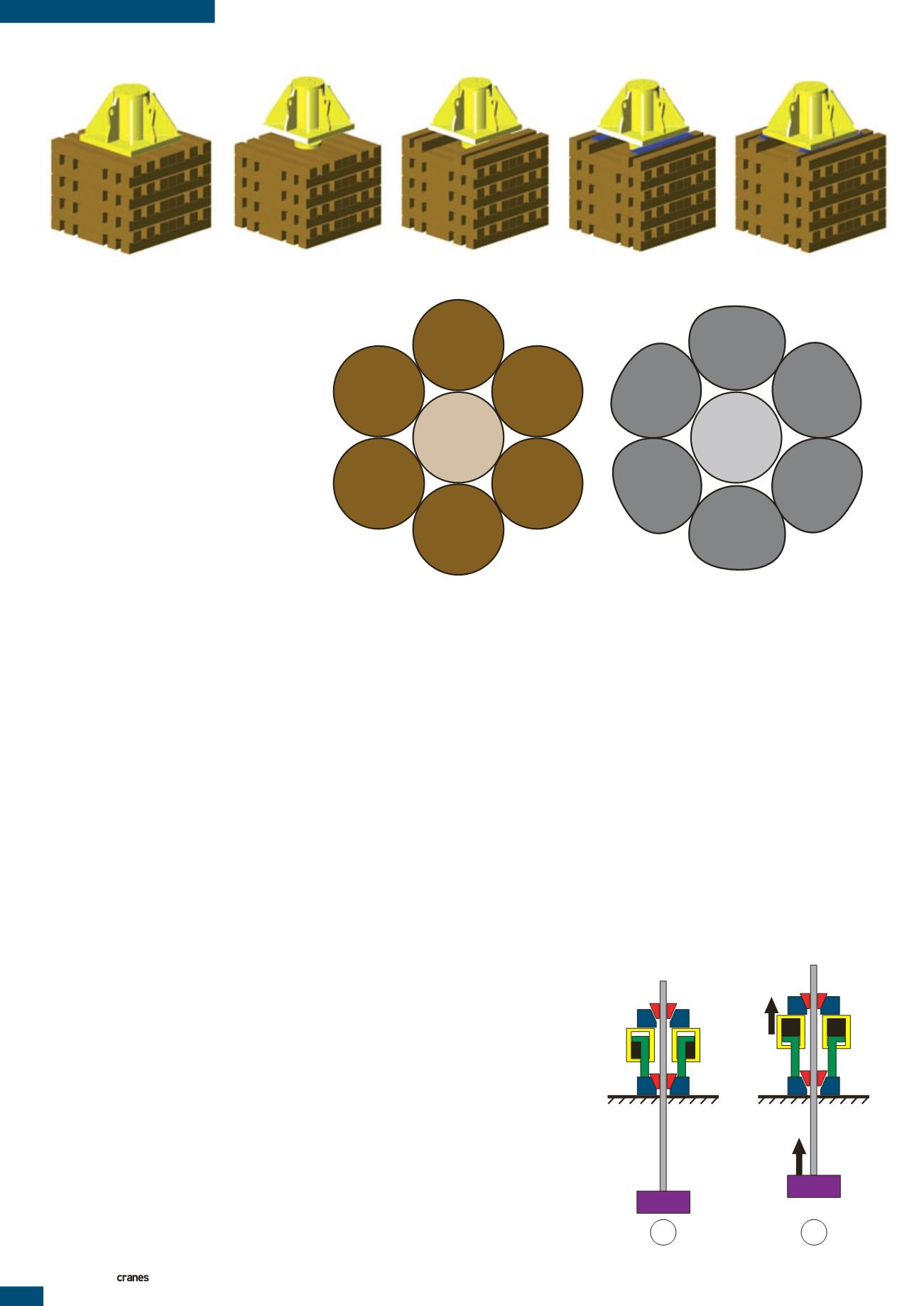

There are seven basic steps in the cycle

of a climbing jack, see Figure 1.

Step 1: jack is set up

Step 2: ram is extended

Step 3: hardwood timbers are placed parallel

underneath the jack (criss-cross)

Step 4: steel strips are placed onto

the hardwood

Step 5: the jack is lowered on the steel strips

and the ram is retracted

Step 6: the void underneath the jack is now

filled up with hardwood

Step 7: the ram is extended continue

from step 2

NOTE:

The steel strips that are used are there

to create sufficient space between the jack

and the previous layer of timbers, so that

the timbers of step 6 can be easily inserted

underneath the jack.

The hardwood that is used as jacking

timber is mostly called ekki or azobe. They

are both of the same Ochnaceae botanic

family. It is found in West Africa (among

others in Cameroon, Ivory Coast, Nigeria

and Sierra Leone). Once the wood is dried

and the moisture content has fallen below

12 % this wood is extremely durable and

hard. Besides jacking timber, this wood

is also used for rail road crossties and

harbour work. Machining with hand tools

(drill or saw) is almost impossible, the

final dimensions are commonly achieved

on a lathe.

According to the Center of Wood

Anatomy Research, azobe has a

maximum compression, or crushing,

strength of 914 to 1,050 kg/cm

2

)

(13,000 to 15,000 PSI). This makes it very

suitable for jacking operations. One thing

to keep in mind, though, is its specific

gravity of 1,120 kg/m

3

(70 lbs/ft

3

), it is

heavier than water and it will sink.

Strand jacks

While on the subject of jacks, it is a small

jump to strand jacks. Strand jacks have

been around for quite a while but not in a

heavy lift application. They were originally

used for post-tensioning of concrete

beams when used for large spans such

as bridges. Nowadays, strand jacks are

found in horizontal applications as pulling

tools, for example, for large load outs, or

in vertical applications as lifting tools on

cranes, lifting towers or gantries. They can

even be used upside down.

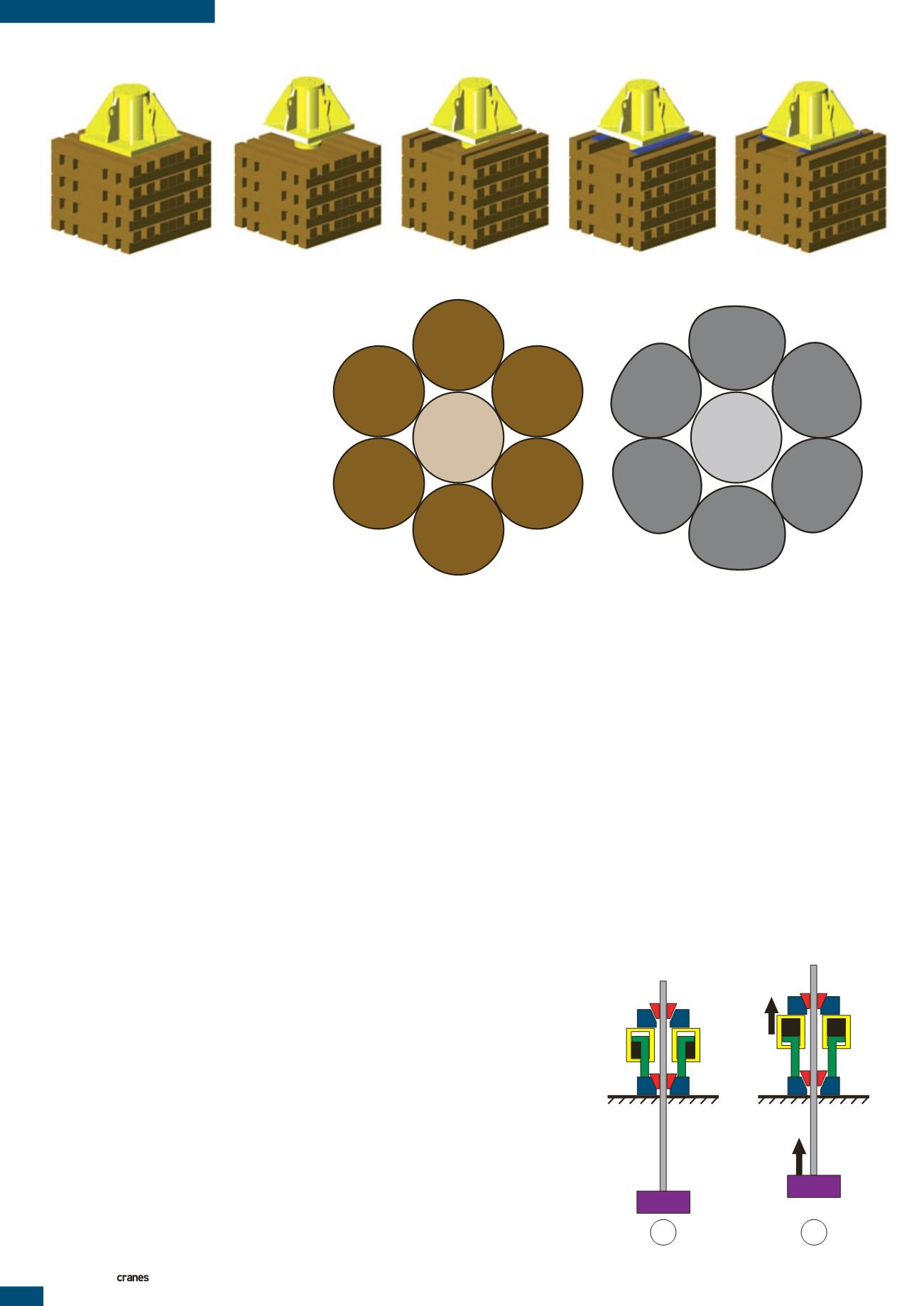

A strand jack is a hollow jack that is

fed with die-formed 18 mm strands of

15 tonne capacity wire rope. The strands

are held in place by wedges. There is a

set in the top of the jack and a set in the

bottom. The strands are die-formed (see

Figure 2) to allow the wedges to have a

tight grip on the strand. Higher capacity

strand jacks use more strands, the strand

pattern is always symmetrical to avoid

eccentric loads on the jack.

To lift a load, the strand jack follows a

sequence of activities, see Figure 3.

Step 1: the load is suspended by the lower

wedges, the upper wedges are open

Step 2: the upper wedges close and the ram

extends. The load is now suspended by

the upper wedges and is raised. This

motion allows the lower wedges to

open and stay open

Step 3: at the end of the stroke the lower

wedges close again and the downward

motion (ram retract) transfers the

load to the lower wedges, this motion

allows the upper wedges to open

and stay open

Step 4: once fully retracted, the upper wedges

close and the ram extends, the load is

now suspended by the upper wedges

and is raised, this motion allows the

lower wedges to open and stay open.

The above sequence repeats itself until

the load has reached its required height.

An advantage of strand jacks is that

one can achieve a high lifting capacity

(750 tonnes or more per strand jack is not

FIGURE 1

Using hydraulic jacks to raise a load to a significant height is a laborious process

Standard strand

Die-shaped strand

FIGURE 2

Standard strand on the left and a die-formed strand for strand jacking

FIGURE 3

Operating sequence for strand jacks

LOAD

START

OPEN

CLOSED

1

LOAD

RAISE

CLOSED

OPEN

2