23

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

NOVEMBER 2013

>

Changing

tides

The popularity of SPMT is

continually growing. As a

result manufacturers are

producing products that

are compatible and capable

of operating on a range

of different work sites.

LAURA HATTON reports

I

n his second practical how-to article

(August 2013 issue page 33) Marco van

Daal differentiated between the various

different types of specialized transport

equipment and the terminology used in its

reference. In his article van Daal defined a

self propelled modular transporter (SPMT)

as a transporter that is propelled by a unit

or a power pack. In this instance, power

comes from a diesel engine and one or

more hydraulic pumps, which drive the

hydraulic drive motors on the axles of

the transporter.

Depending on the type of applications

required, the number of axles on an SPMT

can vary extensively. This has added to

its success throughout the industry and

SPMTs are now used all over the world

at oil and gas construction projects and

other sites for transporting oversize and

overweight objects.

“The great success of SPMTs is based

on the possibility to couple amongst the

different vehicle generations,” explains

Christopher Rimmele, public relations

manager TII sales. “Worldwide more

than 13,000 axle lines of Scheuerle and

Kamag SPMTs are in use and, over the

past twelve months, 1,500 axle line orders

were from ALE, Mammoet, Roll-Lift and

Sarens. The availability of axle lines all over

the world gives a high flexibility to TII

customers as they can rent in or rent out

axle lines in order to cover their demand

of axle lines for their various transport

projects and operations.”

A result of this international availability

generally means that new models of

SPMT work with previous designs and

in some cases, even with competitor

products. The latest generation of SPMT

from, for example, TII, is the Generation

4 of Scheuerle and Kamag SPMT. The

transporter has a compact design, which

allows high point loads due to short

axle distance to minimise the effective

bending moment on the spine beam, the

manufacturer explains.

“In addition, Generation 4 works

SPMT

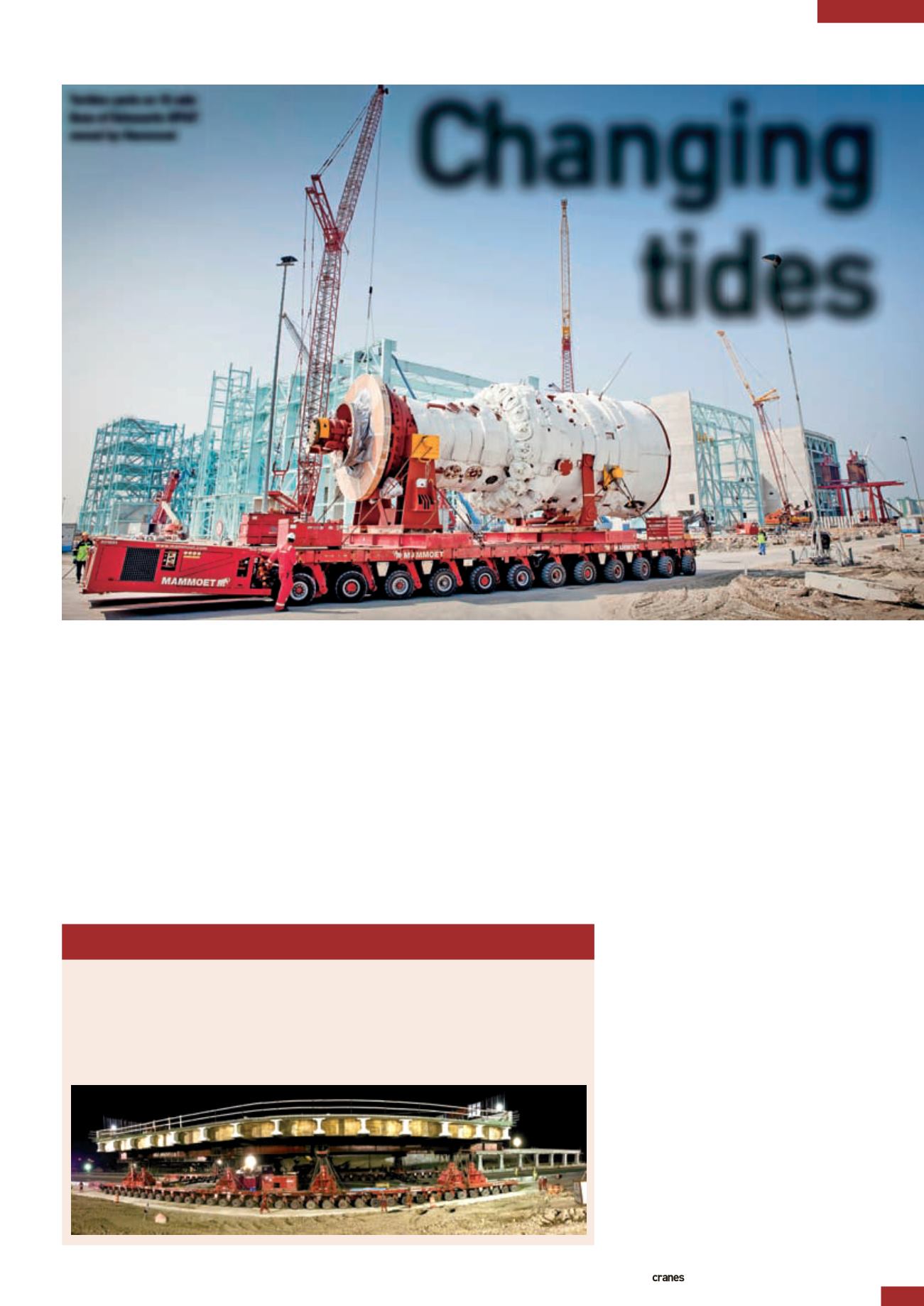

Self propelled modular transporter (SPMT) is used worldwide for a broad range of jobs, from

on-site logistics to shipyard use and in construction. An example of SPMT in action was seen

earlier this year in Oak Creek, Milwaukee, Wisconsin, USA when the Wisconsin Department of

Transportation replaced the Rawson Avenue Bridge.

For the project, Scheuerle SPMT was used using an accelerated bridge construction (ABC)

technique. The SPMT was used to lift and transport the new bridge spans into place.

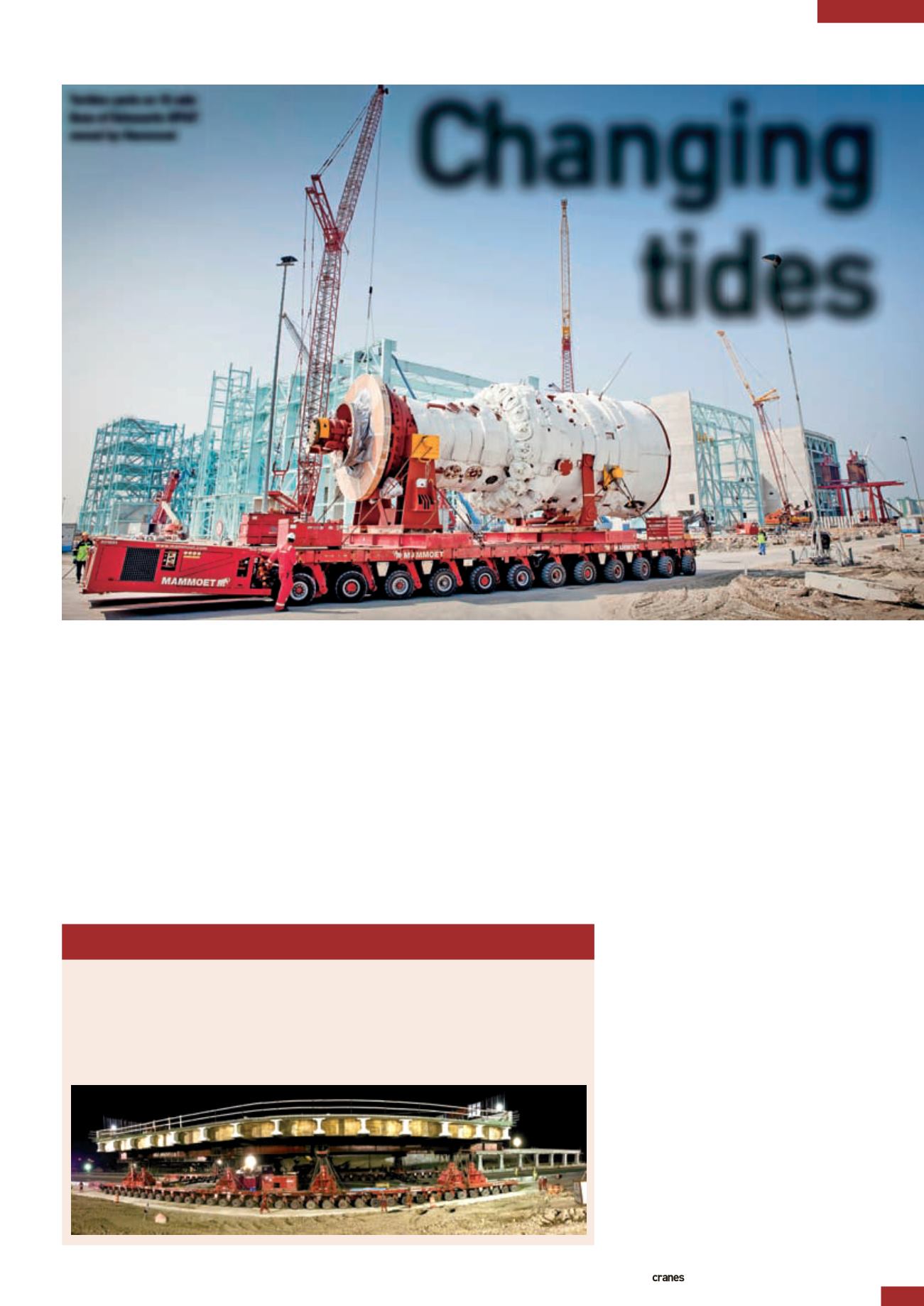

Turbine parts on 12 axle

lines of Scheuerle SPMT

owned by Mammoet

SPMT AT WORK