15

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

NOVEMBER 2013

To be able to complete such a variety

of lifts on a single job site maintenance

intervals for rough terrains need to

be kept to a minimum and operating

systems need to be simple and easy to use.

“Operators should be able to operate them

independently of which machine they are

usually operating,” a spokesperson from

Terex explains, “This means that they

should be easy to use and robust.”

Good transportability and

manoeuvrability are other characteristics

that rough terrains need to have. A

spokesperson from Tadano explains more,

“Having a compact carrier in width and

height improves manoeuvrability and

the ability to navigate smaller spaces for

transportation. Having rough terrains that

meet these criteria in the energy sector in

North America is a major factor, as they

need to move through tight spaces.”

To meet this demand Tadano

introduced the GR-1600XL (for the US

market) and the GR-1450EX (for outside

the USA), a 3-axle compact carrier. The

GR-1450EX /GR-1600XL has a 145 tonne

capacity and the boom is 61 metres.

“The model also has a self-removable

counterweight and outriggers which

are cost-effective and provides ease of

transport without requiring an assist crane,”

a company spokesperson adds. The rough

R

ough terrains are a workhorse of

the crane world, often staying on

site for months at a time, being used

on many jobs with different operators on

a daily basis. In more recent years, rough

terrains are even taking on tasks that would

in the past have been assigned to other

crane types, such as small tower cranes

or all terrain cranes. Their popularity is

mainly due to their greater capacity but

compact footprint, fast setup time and

tight turning radii, a spokesperson from

Manitowoc points out.

“Rough terrains are built for general

lifting duties and are referred to as the

wheel barrow of the jobsite,” Casey Smith,

Link-Belt, adds, “You might use a rough

terrain on a jobsite where you are using it

as a helper crane or you might use a rough

terrain where you have a jobsite that a

crawler crane cannot enter.”

>

Rough terrain cranes

are undergoing some

major design changes

as they start to take on

jobs traditionally done

by other crane types.

LAURA HATTON reports

Changing

landscapes

ROUGH TERRAINS

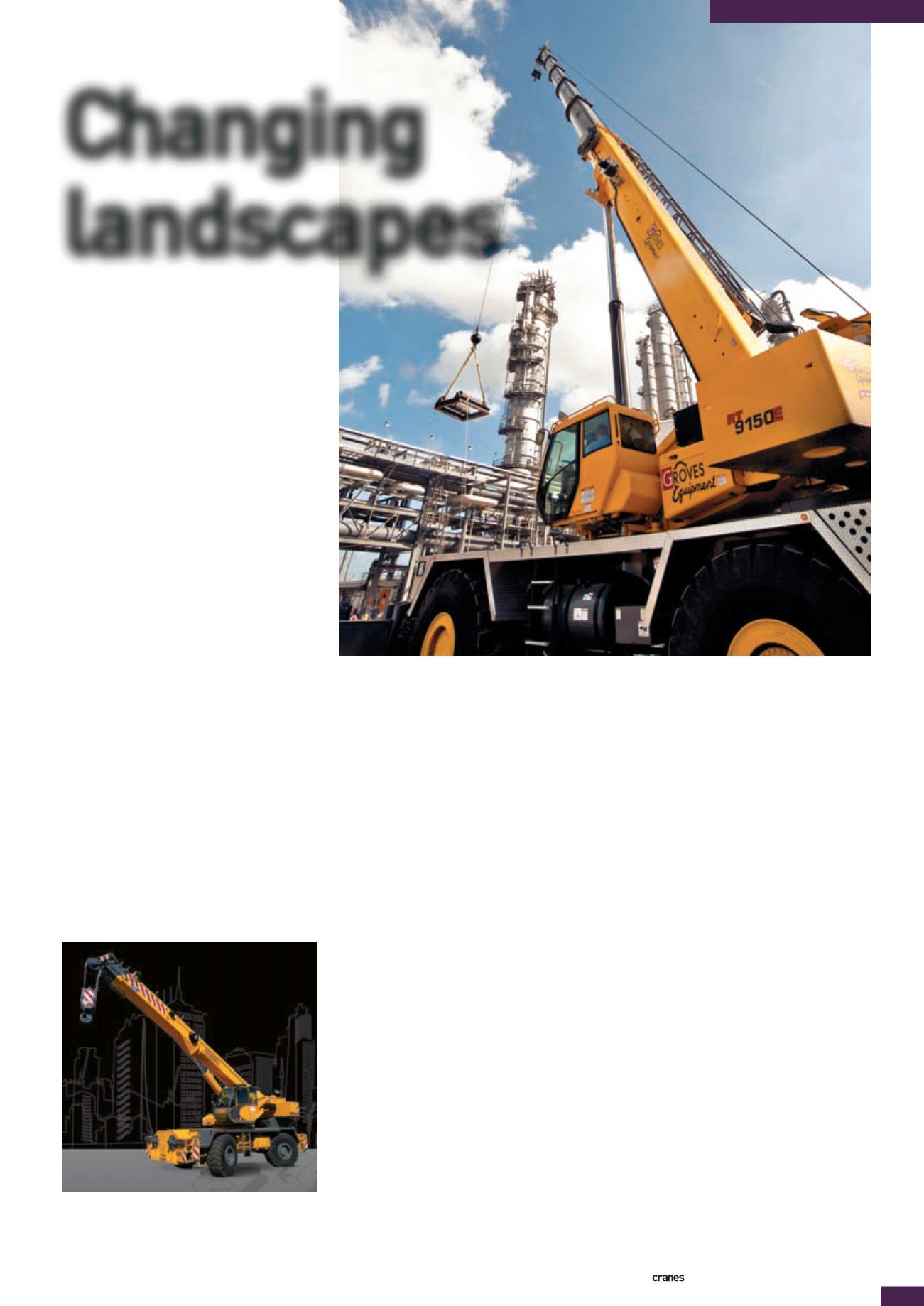

A Grove RT9150E at the

BASF Petrochemical facility

in Grove, Texas, USA

terrains include the HELLO-NET system,

a machine data logging and monitoring

system, as a standard function. It provides

information on operational status, position

and maintenance from owner’s desk, a

company spokesperson adds.

Driving change

Another area affecting the design of

rough terrains is emission regulations,

as Smith explains, “Emissions are one of

the main components for modifications

on our rough terrain Series II technology.

These emission devices add weight and

present a space challenge, but we have

successfully incorporated these devices

without sacrificing the transport weights,

serviceability, and accessibility. For rough

terrain cranes we have made the engine

hood wider to house these devices while

still providing six points of access to the

operator’s cab.”

Despite the challenges presented by

the regulations, crane manufacturers

are finding ways to incorporate the new

engines in the designs. Manitowoc, for

example, has released new models and

redesigned current products with Tier

4 interim engines (Euromot 3B). Crane

manufacturer Sany has also overcome the

design challenges and now offers models

with Tier IV engines in North America and

The Locatelli GRIL8 is one of the newest

rough terrain models from Locatelli since its

acquisition by Media Finanziaria Group