41

SITE REPORT

JULY-AUGUST 2013

ACCESS, LIFT & HANDLERS

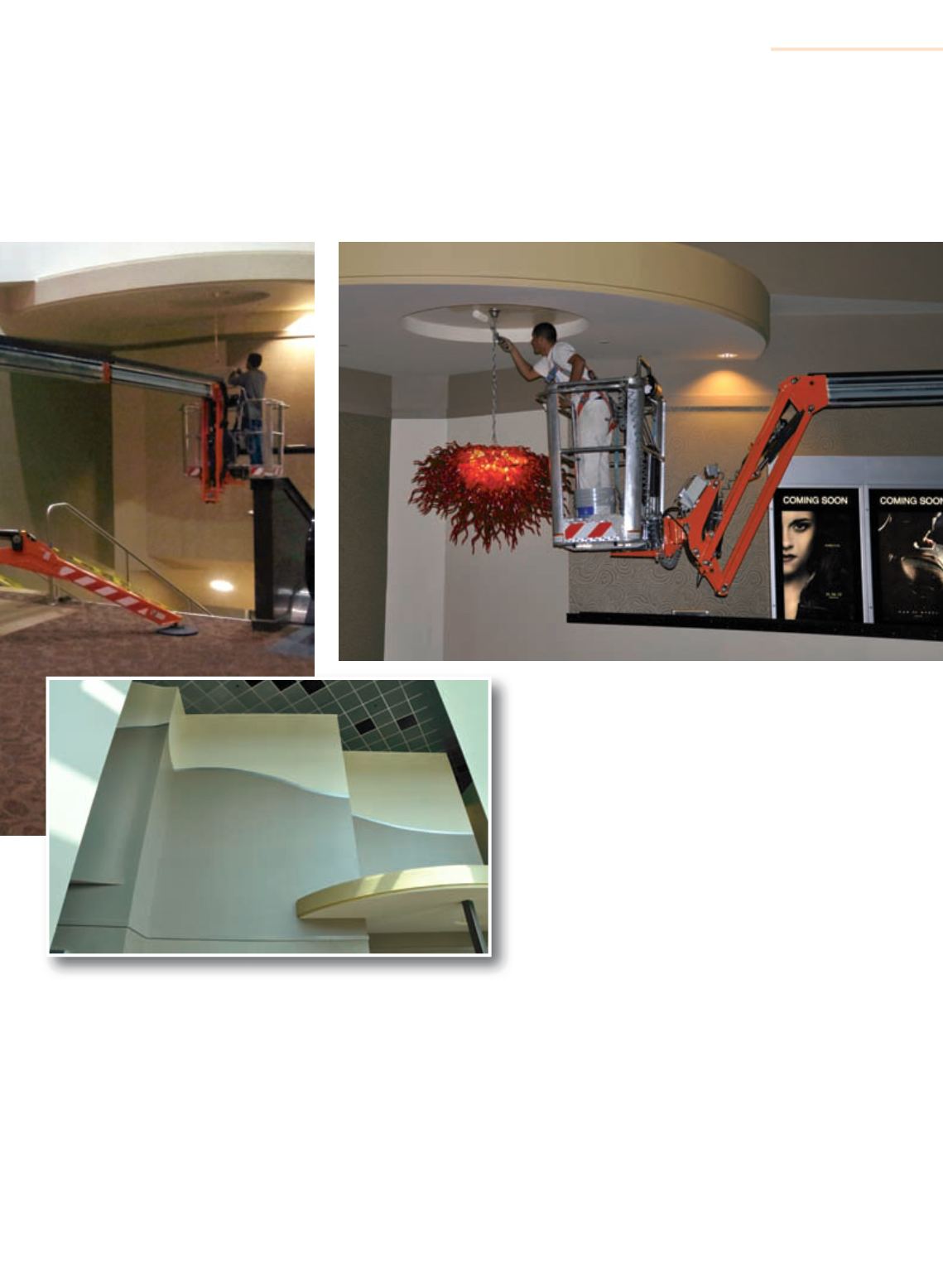

glass pieces that needed to be hand tied to the

chandelier’s frame. We tied 10 to 15 pieces in

an hour’s time, carefully sorting the pieces on

the floor, loading them into a box and sending

someone out in the crawler bucket to tie them.

“We thought we had completed the project

when the first stripe was finished. But, when

the theater owner decided to repaint the stripe,

he also decided to order some additional pieces

of glass to make the chandelier fuller on top.

So, again, we were grateful to have the crawler

boom available for the task.”

Unlimited uses

Without the compact crawler boom, Truesdale

is unsure how she would have completed the

project.

The positive experience, although daunting in

the beginning, has made her eager to put the

machine to use in another project.

“From my experience, the crawler’s uses are

unlimited,” she says. “I can see the value it

would bring to projects in churches, theaters,

auditoriums, gymnasiums – really any place

that features peculiar or unusual spaces

that are difficult to access – as well as more

ordinary applications that require aerial work.

“Would I recommend the crawler to others?

Oh, absolutely, without a doubt. It’s efficient,

versatile, comfortable, and extremely easy to

use. I feel empowered, and I can’t wait to find

the next use for it.”

■

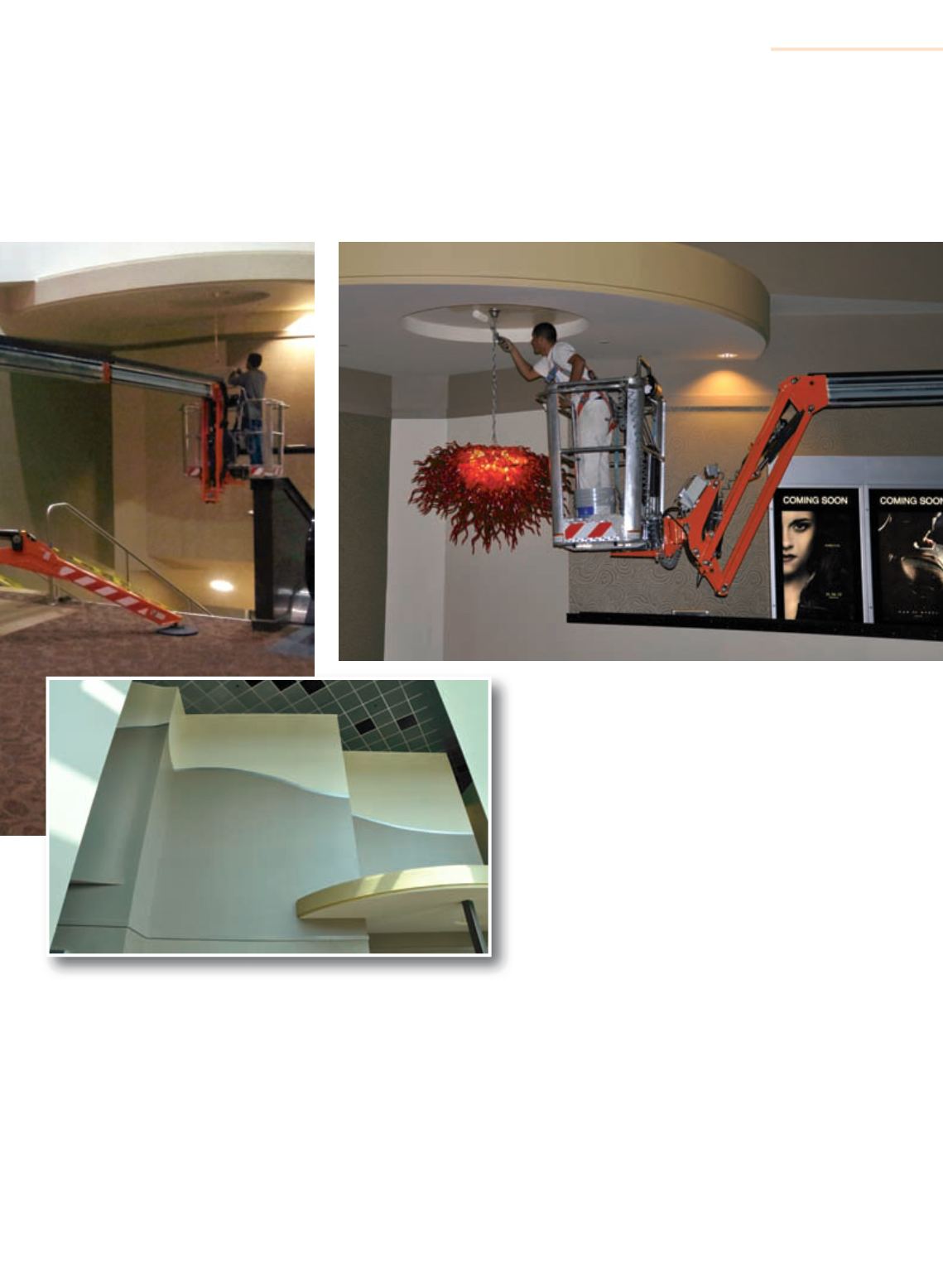

Despite the theater’s limited access, tight corners, and

a variety of obstructions, including the bulkhead over

the bar area, the crawler boom got the job done.

solution

which doesn’t take very long, the control panel

is very accommodating and easy to use, and

the machine itself is quite gentle. We always

felt comfortable in it and able to maneuver into

whatever position we needed to be in without

bumping around or missing the mark. Despite

the theater’s limited access, tight corners, and

a variety of obstructions, including the bulkhead

over the bar area, the crawler boom equipped

us to get the job done.”

By the time she completed the project,

Truesdale felt confident in her ability to use

the crawler boom, which was a good thing,

because after the work was completed, the

ramp removed, and the boom returned, the

theater owner decided to change the color

of the stripe from champagne to silver. That

meant securing the crawler boom a second

time, rebuilding the ramp, and accomplishing

in four nights what had taken the team three

weeks of night work to complete the first time.

“This time we did not have to create the grid,

we knew exactly how to construct the ramp,

and we could operate the crawler boom with

confidence,” Truesdale says.

She also noted that the machine helped

them accomplish a second task. “The theater

owner asked us to build out a chandelier that

hung above the stairwell, slightly lower than

the stripe, and consisted of more than 300

The painting

project

(pictured here)

had many

challenges,

including how

to get workers

elevated

safely, as well

as how to get

the needed

equipment into

the theater.