SAFETY OPINION

46

ACCESS, LIFT & HANDLERS

JULY-AUGUST 2013

THE AUTHOR:

Kevin O’Shea is the director of safety and training at Hydro-Mobile. He has

worked with Mastclimbers LLC, JLG, SGB, Lavendon and Mastclimbers LTD UK

(now Harsco). O’Shea serves as Chairman of IPAF’s North American Council,

Chairman of the SAIA’s MCWP Committee, is a member of the SAIA/OSHA

Alliance Team and has won various awards over the years, including: IPAF

Safety Champion 2009, 2010 and 2013; SAIA Council Chairperson of the Year

2009 and SAIA ‘Coupling Pin’ Award 2010.

Kevin O’Shea

, director of safety and training at Hydro-Mobile,

talks about the newest piece of kit on the mast climber block.

T

he transport platform (TP), is the newest

type of mast climbing work platform

(MCWP) on the market, and most

manufacturers of MCWPs offer a TP model.

It is quickly becoming a popular method of

getting personnel and materials to various

levels of the structure and TP use is spreading

quickly throughout North America. Many rental

companies and equipment owners can see the

advantages of the TP, but not all realize the

necessary requirements to be able to operate

or rent such a unit. The TP offers flexibility in

the rental fleet and it provides high levels of

productivity at an attractive price. But, what is

the TP? How is it different to a material hoist or

construction elevator? And what do you need to

know before you purchase or rent a TP?

There are three types of hoist generally

available:

■

Material Hoist

The material hoist is used to lift only materials

from the ground up to levels of the structure.

The transport platform –

■

Defining Features

The TP is different from the both the material

hoist and the personnel/material hoist in a

number of important ways:

Its speed is limited to 40 feet per minute. This

significantly slower speed (personnel/material

hoists can travel at hundreds of feet per minute)

is easy enough to provide excellent productivity

within its intended environment, but is slow

enough to make it easier to control, and it

therefore requires a less sophisticated operating

and drive system.

Its capacity is limited. The TP is usually

capable of lifting personnel to only 50 percent of

its capacity.

Everyone who uses a TP has to be trained

as an operator. The rationale being that in its

operating environment the unit’s frequency

of use doesn’t require a full-time operator.

Subsequently everyone who uses it has to be

trained as an operator.

The unit is setup to be further away from the

structure than the personnel/material hoist. Most

TPs are set-up about 18-inches away from the

structure and when it gets to its delivery level

integrated door/ramp arrangement is activated.

This is very different from the personnel/

material hoist which is usually set-up about

2-inches away from the structure. However

when travelling at 18-inches away there is no

chance of a shear hazard so the platform cage

arrangement doesn’t have to be so enclosed as

the personnel/material hoist does.

Most TPs can be used as ‘material only units.’

Personnel/material hoists don’t have this ability.

There are other differences between the

units, but they essentially operate in different

environments so each has been designed to

operate in its own particular way to suit its

environment.

TPs are ideal for medium-sized projects.

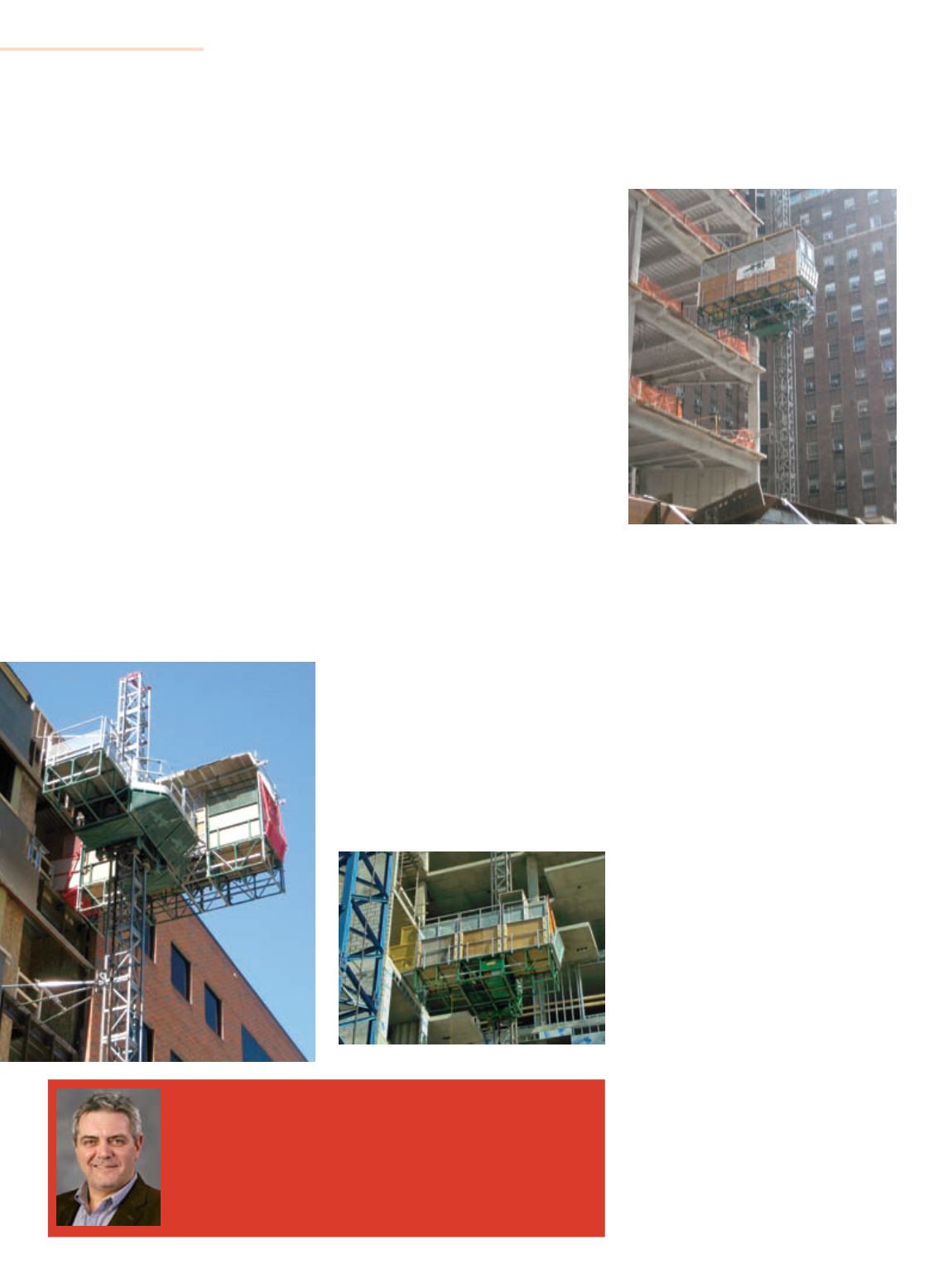

TPs are typically

set-up 18-inches

away from a

structure.

A Hydro-Mobile

TP at a jobsite.

Personnel are prohibited from riding in a

material hoist. It is loaded with material by the

operator at the ground level and unloaded by

workers at the delivery level above at one of

any number of floors set up to receive it. The

material hoist is covered by the ANSI standard

A10.5.

■

Construction Elevator or Personnel and

Material Hoist

The personnel and material hoist is used to

lift, as its description explains, both personnel

and materials to designated loading/unloading

points on the structure. Most of us in the

construction industry have ridden in this type of

hoist at some time. It is designed for use in high

level construction environments to deliver high

volumes of personnel and materials in a quick

efficient fashion. The personnel and material

hoist is covered by its own ANSI standard,

A10.4.

■

Transport Platform

The transport platform has elements of

both the material hoist and personnel and

material hoists. The original reason for the

existence of the TP was that in medium-sized

construction projects where the installation of

a personnel and material hoist was considered

to be unsuitable due to complexity, cost and

productivity challenges, some other safe

and productive method was required to get

personnel and materials up into the structure.

The transport platform is covered by ANSI

A92.10.