46

SITE REPORT

LIFTING

ACT

OCTOBER 2013

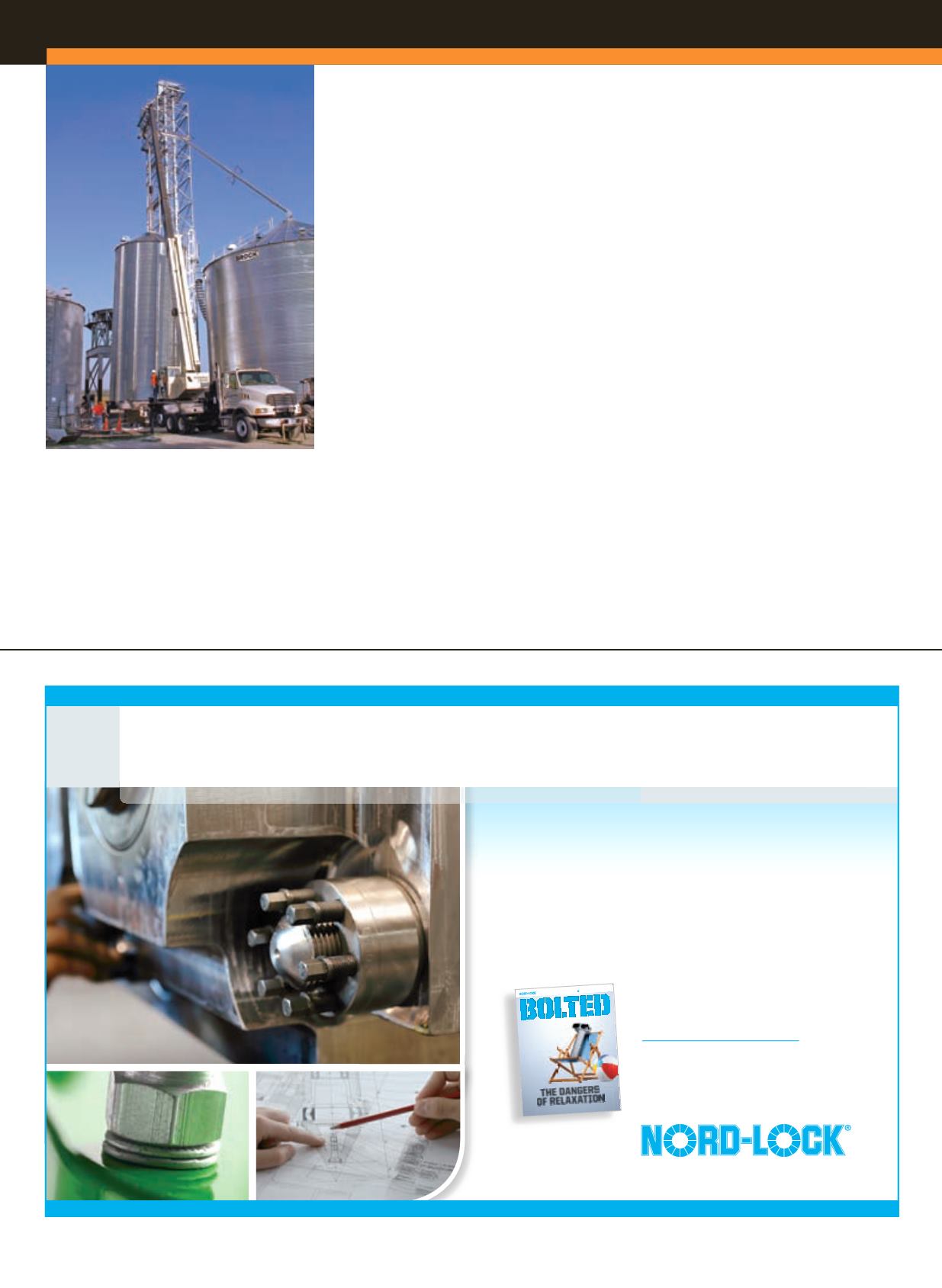

For the most part, the bins are

assembled on the ground and then the

cranes lift the pieces into place for crews

to bolt together.

“Our National cranes are great for that

step, and the various sizes we have allow

us to fit different needs most effectively,”

Larry says. “National has a good

reputation for quality products, so when

we were looking for cranes, that’s where

I started. We bought a used one, and it

performed well. That sold us on buying

additional units.”

For larger jobs, the company purchased

two 110-ton Grove TMS9000E truck-

mounted cranes. The mobile units have a

maximum tip height of 235 feet, and the

company added a hydraulic luffing jib that

allows set-ups in tight areas. The company

also chose the full counterweight package,

which maxes out at 48,500 pounds.

“That size machine really fits our

markets well,” says Matthew. “Larger bins

mean heavier and higher picks, and the

TMS9000 gives us the lifting capacity

we need. The luffing jib will fold up to a

20-degree angle, giving us further reach.

That’s important in an area where we have

to keep a small footprint. We also like

that they have one cylinder that pushes

the boom out in stages. It gives us better

capacity than other systems we’ve seen.

The full counterweight package gives us

flexibility to add capacity as needed.”

Matthew says mobility was also a factor

in their crane-buying, decision-making

process.

“Both the National and Grove cranes

allow us to drive from project to project,

which saves time and is more efficient

than moving a larger crane in pieces and

taking hours or days to set it up,” he says.

“With these cranes, we can pull onto the

site and be ready to pick in minutes.”

The Unverfehrts worked with Kirby-

Smith Machinery’s St. Louis Branch

Manager Ray Jost on the purchase of both

the National and Grove products.

“Like us, Kirby-Smith understands the

importance of backing what they sell

with exceptional service,” says Larry.

“We’ve developed a great relationship with

Kirby-Smith, working with Ray Jost and

Dave Hoeft, before he retired. They’re

knowledgeable in what the cranes will do,

and Kirby-Smith service techs are well-

trained to handle anything we’ve needed.”

Gus and Irene couldn’t be prouder of the

company and their family. “Much of the

growth we’ve experienced is directly due

to Larry, Kevin and their families’ efforts

in seeing an opportunity and running

with it,” says Gus.

■

During assembly, Gus C. Unverfehrt Farm

Supply uses a National boom truck to lift

grain bin pieces into place.

Your trusted partner for

bolted joints

The Nord-Lock Group is a world leader in

bolt securing systems

. We offer a unique

combination of bolting expertise and a wide

product range, including wedge-locking

solutions and Superbolt tensioners.

Discover safe and easy bolting for your

critical applications today!

DAKARRALLYDRIVERONWHY

HEHASCHOSENNORD-LOCK

AMAGAZINE ABOUTOPTIMISING BOLT SECURING

# 1 2013

HOLDINGTOGETHER

UNDER8,000TONS

OFPRESSURE

FULLY PRESSED

THEULTIMATESOLUTION

FORSTEELCONSTRUCTION

NEW SCWASHERS

AWORLD-FIRST

MADEPOSSIBLE

BYSUPERBOLT

THE REUSABLE RIG

HOW TOENSURE TIGHTBOLTED JOINTS

THE DANGERS

OF RELAXATION

COMPLIMENTARY

SUBSCRIPTION:

Bolting tips and case studies from

the bolting experts.