45

LIFTING

SITE REPORT

OCTOBER 2013

ACT

New business came from selling feeding

equipment to dairy farms, and the

company began selling silo unloaders and

became a feed dealer. In the late 1970s

“things really snowballed,” when they

began selling grain bins to area farmers.

At the time, farmers would erect the bins

themselves. But as the grain market grew

with increased yields, so did the need

for larger bins. In the late 1980s Larry

Unverfehrt put together the company’s

first crew to set up grain bins.

Major driver

“It’s now one of the major drivers of our

business,” he says. “We’ve continued

to expand and offer commercial work

erecting bins for elevators.”

According to Matthew Unverfehrt,

farmers and commercial customers can

have vastly different needs.

“Farmers only deal with the trucks that

come from their fields, bringing grain to

their bins,” says Matthew. “Commercial

businesses deal with a larger volume

that comes from numerous farms, often

handling hundreds of trucks a day.

Farmers are generally looking for a bin

system that handles about 6,000 bushels

per hour, whereas an elevator may need to

accommodate 20,000.”

The size of the bins needed to handle

the varying volumes is also vastly

different, as farmers typically put up

60,000-bushel storage units. Commercial

bins are often big enough to store 750,000

bushels or more. Private, individual grain

bin projects require about a month to

complete, while larger commercial set-

ups can take as long as three months. The

Unverfehrts can have as many as 10 to 12

grain bin erection projects going at once.

“It all depends on the size and scope

of the set-up as to how long it will take

to complete – we’re basically a turnkey

operation,” said Larry, noting that they

Cranes

and grains

I

n 1954, Gus and Irene Unverfehrt

started a farm, raising hogs and

cattle on several acres near Centralia,

IL. The idea of owning a farm supply

business never crossed their minds.

“I was just trying to get by raising

livestock,” says Unverfehrt. “During those

early years, the market was in East St.

Louis, so I’d take livestock there once a

week or every couple of weeks. While I

was there, I’d pick up supplies. Neighbors

started asking me to pick up items for

them too, and that’s really how I got into

the farm-supply business.”

The business took root from those

periodic supply trips, and by 1961 the

couple formally started the business.

Today, Gus C. Unverfehrt Farm Supply

is a third-generation family business. Sons

Larry and Kevin Unverfehrt manage day-

to-day operations. Larry’s wife, Kathy and

their sons, Matthew and Tyler, and their

daughter, Jennifer, work for the company.

Mathew’s wife, Katie, also works in the

office and Kevin’s son, Adam, oversees

electrical work and runs service calls.

Although the business came about

by chance, once it was established, the

Unverfehrts became active in growing it

and adding to the supply inventory. In

time, the business would begin offering

feeding, watering and milking systems for

livestock, as well as other products and

services.

“For the most part, we were geared

toward livestock farmers,” says Gus.

only subcontract out large concrete pours.

“Our own staff does more than 90

percent of our jobs, and that number

continues to increase as we have started

doing our own electrical work,” he says.

“To increase efficiency, we have multiple

crews and each focuses on a particular

aspect of the project: concrete, building

grain bins, building augers, assembly of

the grain legs, etc. That way, once the

concrete crew is done with its work, it

can move on to another project while the

other crews come in and do their work.”

As the need for storage capacities

grew, so did the Unverfehrts’ need for

larger lifting and erection equipment.

The company began purchasing National

boom trucks in the mid-1990s, and now

has 28- and 40-ton units.

Three generations of Unverfehrts are active

in operating Gus C. Unverfehrt Farm Supply,

including (L-R) Gus and Irene, their son,

Larry, and his son, Matthew.

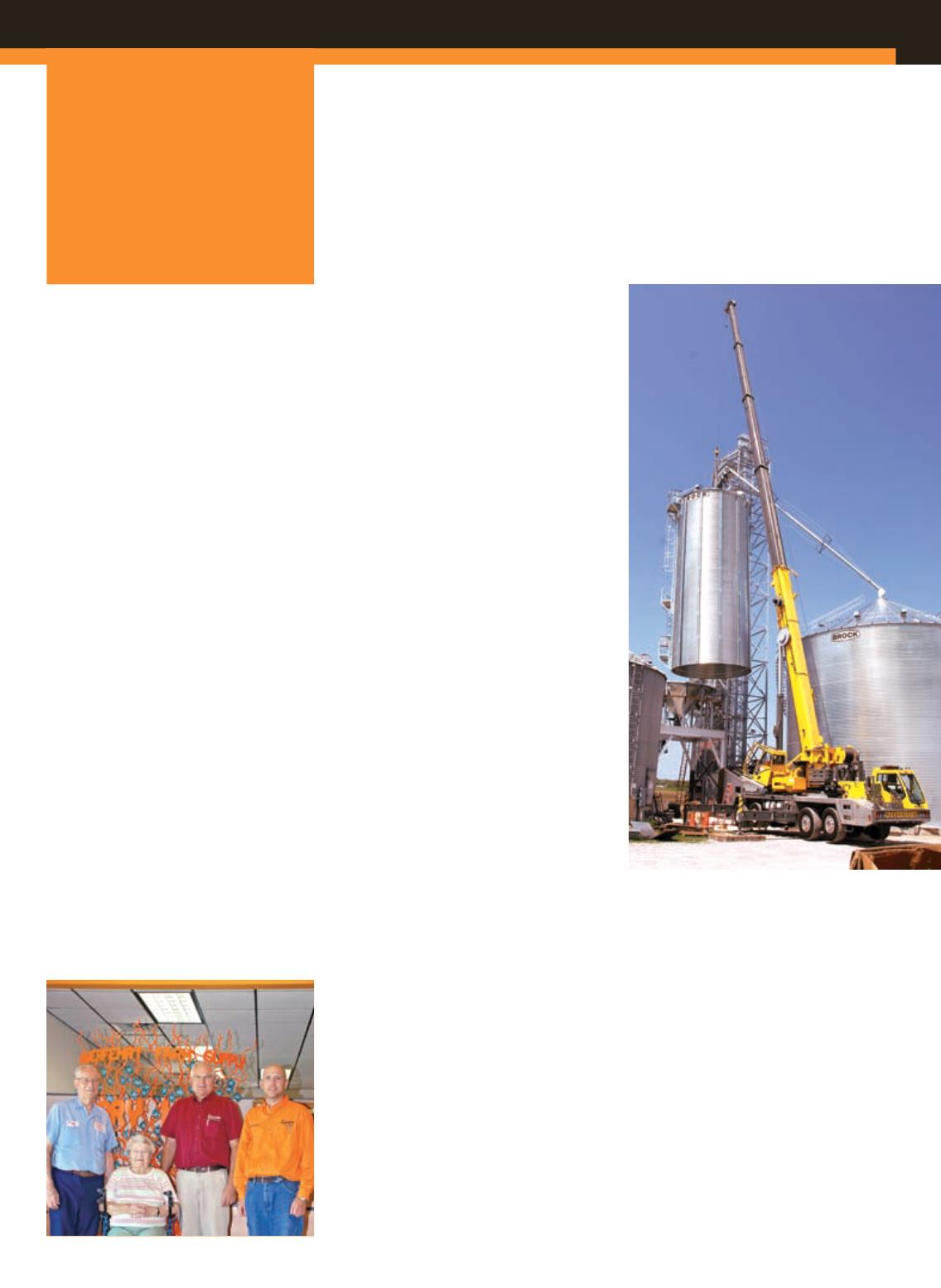

Gus Unverfehrt Farm

Supply utilizes National

boom trucks and a Grove

truck crane to erect

grain bins.

Operator Roger Boozer

lifts a grain bin into

place on a farm using

a 110-ton Grove

TMS9000E crane.