49

TRANSPORT

SITE REPORT

OCTOBER 2013

ACT

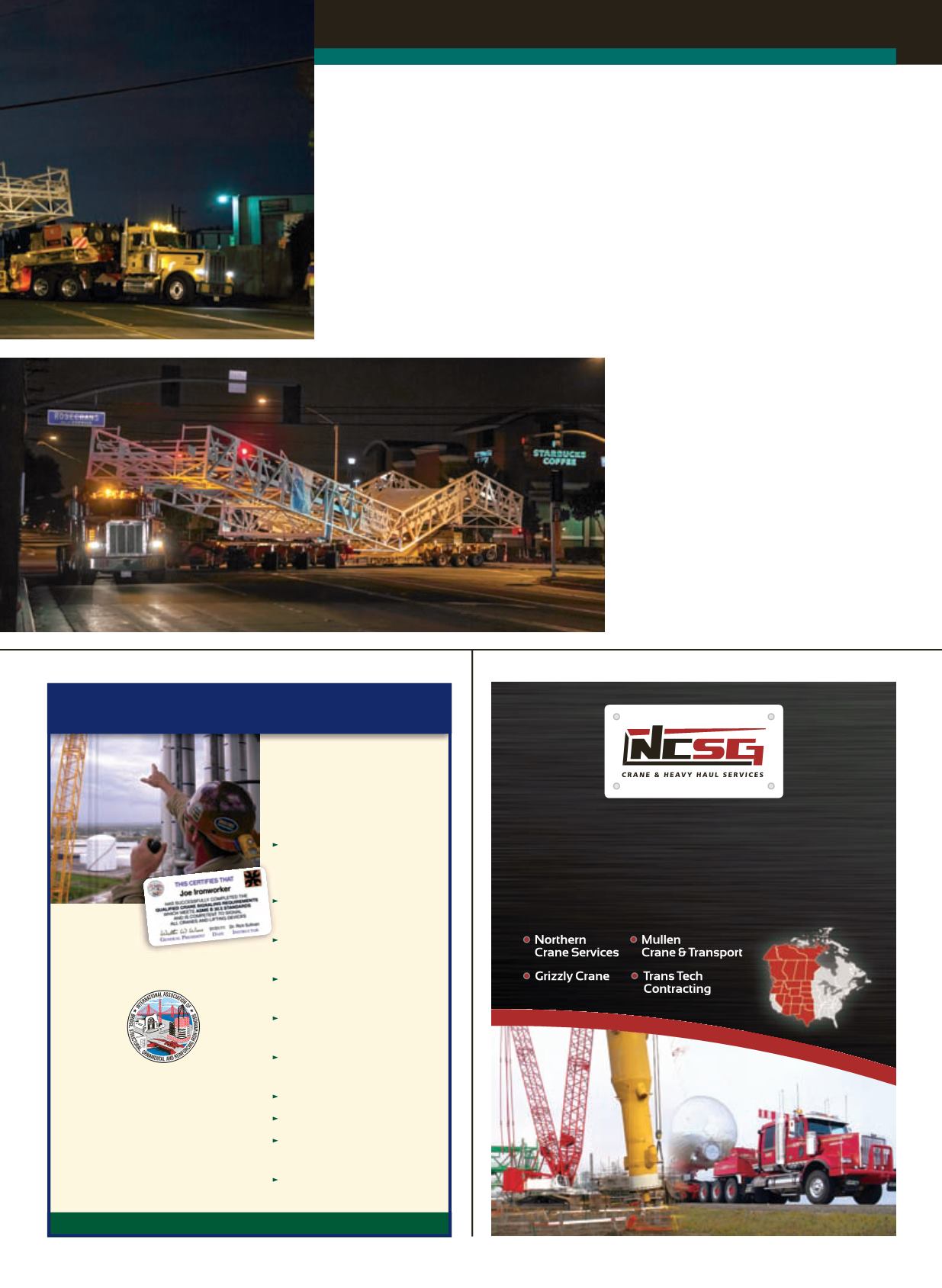

Maneuvering beneath power lines and

past railroad crossings were all part

of the plan for Heavy Transport. The

travelers were hauled on a Scheuerle

Wide-Combi trailer system.

“It is a challenge in itself to move

something this size,” says Kevin Reese,

Heavy Transport’s Operations Manager.

“It is an even bigger challenge to do it at

night.”

Throughout the five consecutive nights

of the move, Heavy Transport followed the

Bragg Companies’ Personal Accountability

Safety Survey (PASS). Under this program,

Bragg employees assess the risk, analyze

how to reduce the risk and act to ensure

safe operations before beginning any task.

“Heavy Transport would like to

recognize fellow SC&RA members West

Coast Permit Service and Kenco Bucket

Trucks for their help,” notes Reese.

“Everyone helped to make this project a

huge success.”

The original plan called for Heavy

Transport to haul all five sections

to the Port of Oakland. However, to

save Caltrans time and money on the

hauling of the travelers, Heavy Transport

recommended the use of a barge. Due

to the multiple entities and unions

involved, others performed the loading

and unloading of the units and Westmont

Industries assumed responsibility for the

transport by barge.

A few days after Heavy Transport

completed its work, the barge sailed into

the San Francisco Bay under the existing

Bay Bridge.

This was a profitable lump-sum project

that was completed ahead of schedule

with zero incidents and zero lost-time

accidents. The 250 total miles of the move

itself required 400 man-hours.

“There were no unexpected issues on the

move other than some wet weather,” says

Reese. “We find the best method is to plan

the work and then work the plan.”

■

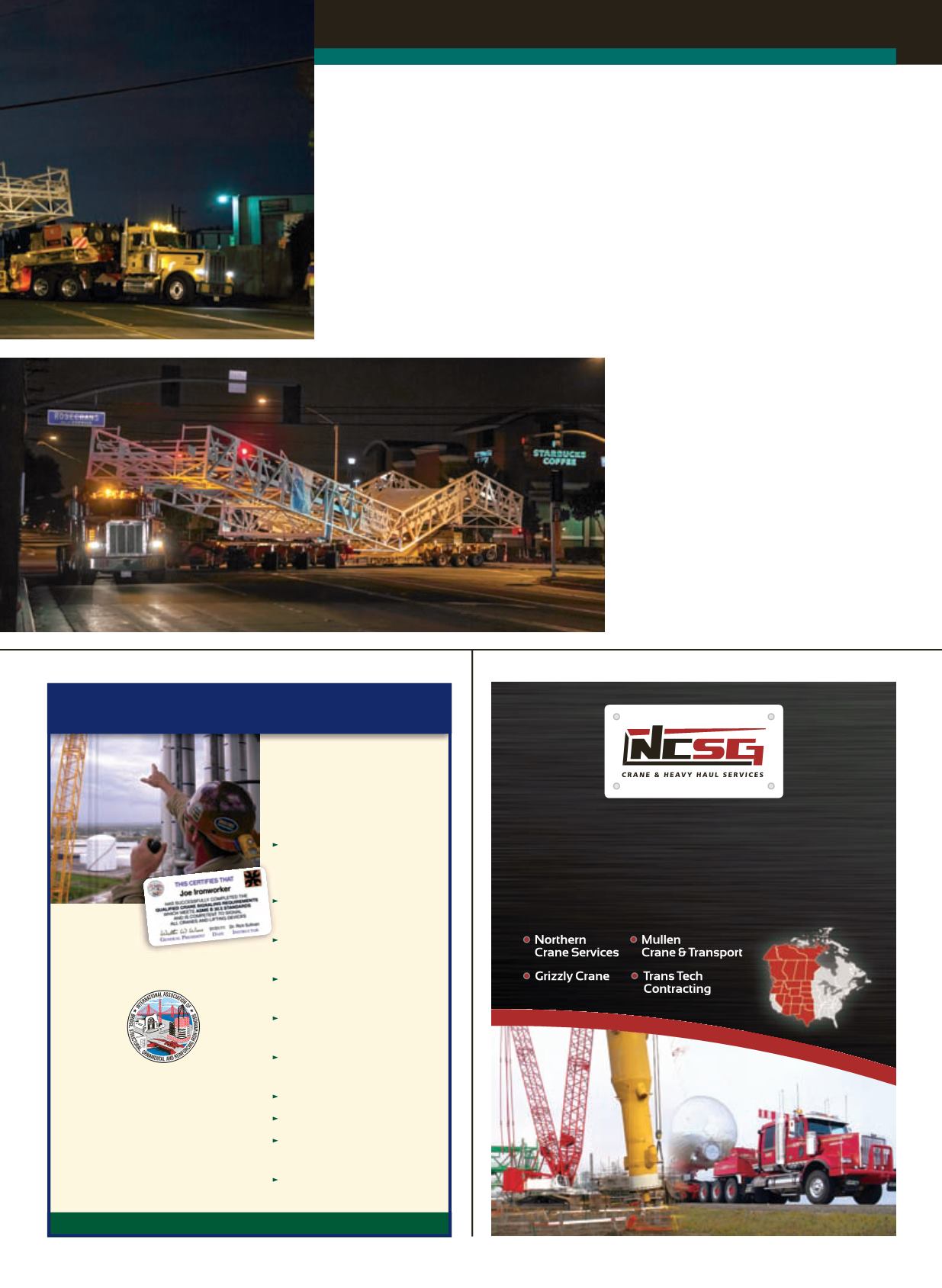

There was no time for a quick stop at Starbucks

while negotiating this 90 degree turn.

Toll Free

1-855-560-5050 |

LIFTING AND HEAVY HAUL

SOLUTIONS PROVIDER OF CHOICE

Throughout the energy corridor of western North America

F o l l ow u s o n F a c e b o o k , Tw i t t e r & Yo u Tu b e

Can You Afford

NOT to Hire Us?

w w w . i r o n w o r k e r s . o r g

8 0 0 . 5 4 5 . 4 9 2 1

w w w . i m p a c t - n e t . o r g

Over 3,000

Contractors

& Over 100,000 Ironworkers

Our Customers Receive

these Benefits at

NOAdditional Cost

:

Recognized as Construction

Industry’s Highest Training

Requirements

Ironworker Qualified Signalman

Training meets ASME (B30)

Ironworker Qualified Rigging

Training meets ANSI (A10.42)

80 Classroom Hours of

Rigging & Crane Training

1,200 Hours Minimum of

On-the-Job Training

Trained & Verified by Professional

Ironworker Instructors

State-of-the-Art Training Materials

Online Tracking System

Network of over 150 Training

Centers in the USA & Canada

Certified by the U.S. Department

of Labor

One

Wrong Signal

Could CostYou

Million

$