TEREX

SITE VISIT

27

DECEMBER 2013

ACT

Terex Waverly’s transformation to lean

is almost complete, although with this

manufacturing process, lean is never

finished, according to Dan Slater, vice

president/general manager, Terex

Cranes North America.

of quality assurance is a good design.”

He points to a ‘Graveyard of Issues’

bulletin board that shows quality issues

that are now dead.

“Quality starts with a good design and

good suppliers,” he said. “One of the lean

manufacturing disciplines is that you build

in quality, not inspect it in.”

Each crane that is ordered starts with a

serial number and a Green Book, which

contains a paper trail of the assembly of

the machine.

“The Green Book is a machine’s assembly

log,” he said. “The size of the Green Book

has doubled and even tripled over the

years because of our quality system.”

Another large-scale improvement

instituted by the Quality Team dealt with

paint quality. Using warranty feedback

and VOC information, it was assessed that

corrective action was needed.

“We didn’t have consistency in our paint

performance,” said Hovanec. “We did a

lot of research and testing and came up

with a solution to use one suppler, Valspar,

for all our paint, both powder and liquid.

We’ve seen marked improvement in

our corrosion resistance. Our new paint

mixture was enhanced five times for its

corrosion resistance. The performance of

our paint is much, much better.”

The Quality Team assesses every part

and parcel in the cranes produced in

Waverly. “It’s a never-ending process,”

Hovanec explained.

Response to the evolution of the Waverly

facility has been altogether positive,

although there’s much more to be done,

Slater said.

Leaders of the Terex Waverly Quality Team

include Lee Linderkamp, senior quality

engineer; Andrew Hall, quality manager;

and Mike Hovanec, director of purchasing/

quality. This team tracks deficits from the

moment they are reported until they are put

to rest in the ‘Graveyard of Issues.’

“This company used to be one in which

the factory told the users what they

needed, and we’ve flip-flopped that,” said

Slater. “We now focusing on several new

initiatives, one, which is enhancing service

and providing customer quality; and two,

reducing complexity.”

Take booms, for instance. The company

produces 35 to 40 different types of

booms. Right now he has assigned a team

to look at booms and assess how to reduce

the amount and complexity.

“We will ultimately reduce what we offer

but it will be what the market wants and

needs,” he said. “We want to be easier to

do business with.”

A component of being easier to work

Plan Every Lift.

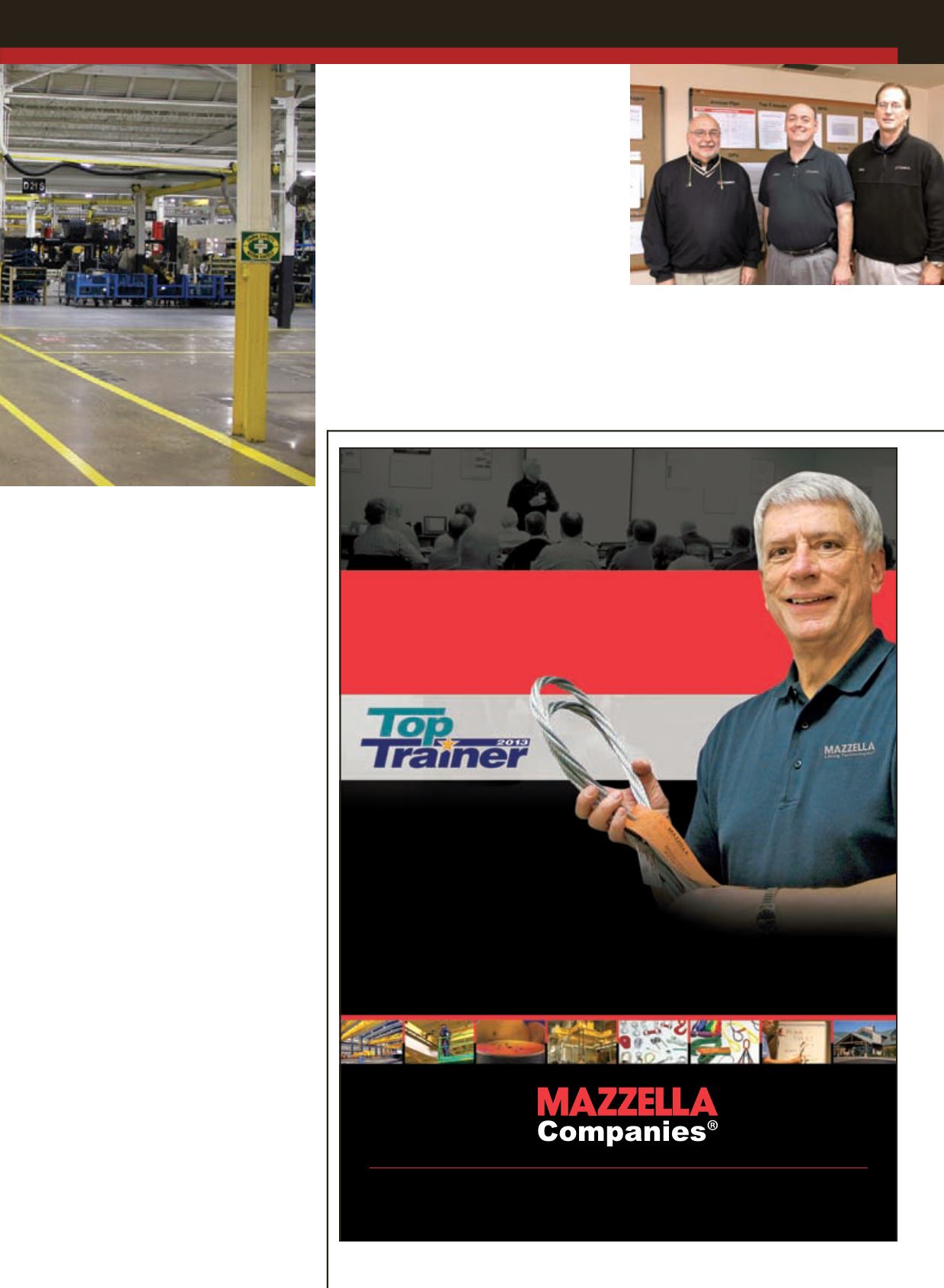

Mazzella Companies proudly employs

two “Top Trainers” recognized by

Crane & Rigging Hot Line Magazine.

Larry Petkovsek

Lifting Specialist

2012 Top Trainer

Honorable Mention

Al Abel (Above)

Lifting Specialist

2013 & 2008 Top Trainer

Honorable Mention

Mazzella Expertise…

Ŷ

Crane, Sling, Hoist &

Rigging Training

Ŷ

OSHA Compliance for Cranes,

Slings, Hoists & Rigging Hardware

Ŷ

Complete Site Assessments

All Mazzella crane, sling, hoist and rigging trainers have been accredited

through Industrial Training International, Inc. We train to OSHA and ASME

standards and FDQ LVVXH FHUWL¿FDWHV IROORZLQJ SURJUDP FRPSOHWLRQ

Call us today for your OSHA compliance needs!

Toll-free: 1.800.362.4601

▶