34

ACT

DECEMBER 2013

PRODUCT FOCUS

SPMTs

haul services throughout the U.S.,” said

Taylor. “We took a team to the Scheuerle/

Kamag facility in Germany in July to

learn the operational features of the K-25

trailers and K-25 Power Booster.”

Power Booster demo

For demonstration purposes, the K-25

Power Booster was coupled to an old

Goldhofer transporter and a new K-25

transporter, showing its compatibility and

adaptability. The K-25 Power Booster was

demonstrated in several configurations,

including as a push truck, on public roads

as a trailer combination and as a self-

propelled transporter.

“What is great is the versatility of usage

for the K-25 Power Booster,” said Taylor.

“It can be used as a push truck behind

a prime mover, or once the drive gear

is switched off, it can be part of a trailer

combination.”

The K-25 Power Booster was also

designed for in-house transports. The

drive unit with the PPU can be controlled

as a self-propelled transport combination

using a mobile control unit.

“For example you might need to pick

up a transformer at a facility and use

the K-25 Power Booster to move it

through the plant,” said Taylor. “Then you

connect with a prime mover to haul the

transformer on public roads and use it as

a push truck on steep hills, so you don’t

need to go to the expense of another prime

mover. Then once you get to the power

plant, you disconnect from the transport

system and move through narrow roads to

the installation site without mobilization

of cranes or other equipment.”

“We think the K-25 Power Booster will

be a top product in the U.S. and Canada,”

said Roland Fischer, area manager of sales

for TII Sales. “Many of our customers are

interested and so are the customers of our

competition. It is a versatile product that

offers many advantages in transport and

moving services.”

Stephen Crawford, sales manager of

Precision Enterprises Inc. (PEI), said

reception to the K-25 Power Booster has

been huge.

“We call it a mini SPMT, but it can be

driven or dragged home,” he said. “When

you get to the jobsite with the K-25, you

don’t have to worry about how to get the

prime mover out of the way. With the

Power Booster, you unhook the prime

mover and park it in the parking lot.

That’s a major selling point, is that you can

eliminate the need for the prime mover

once you get to the jobsite. Plus, with the

SPMT, there’s a lot more hook up than

just pushing a button, which is what you

do with the Power Booster. It’s not a big

transition to unhook the Power Booster,

just one guy to push a button and unhook

a couple of hoses. It’s a time-saving

device.”

Heavy lift and transport company

Mammoet recently signed a deal for 650

axle lines of Scheuerle SPMT. This will

bring the total number of axle lines in

Mammoet’s fleet to more than 3,000.

“We meet a lot of demand for intelligent

transport solutions around the world,”

said Jan Kleijn, CEO, Mammoet. “This

substantial acquisition is a strategic

investment in Mammoet’s fleet.”

Herman Smit, Mammoet COO, said

SPMTs play a pivotal role in engineering

solutions and safe delivery of services.

“We are convinced of the quality

Scheuerle has delivered for the past 30

years,” Smit said. “The purchase supports

our project requirements for 2014 and

thereafter.”

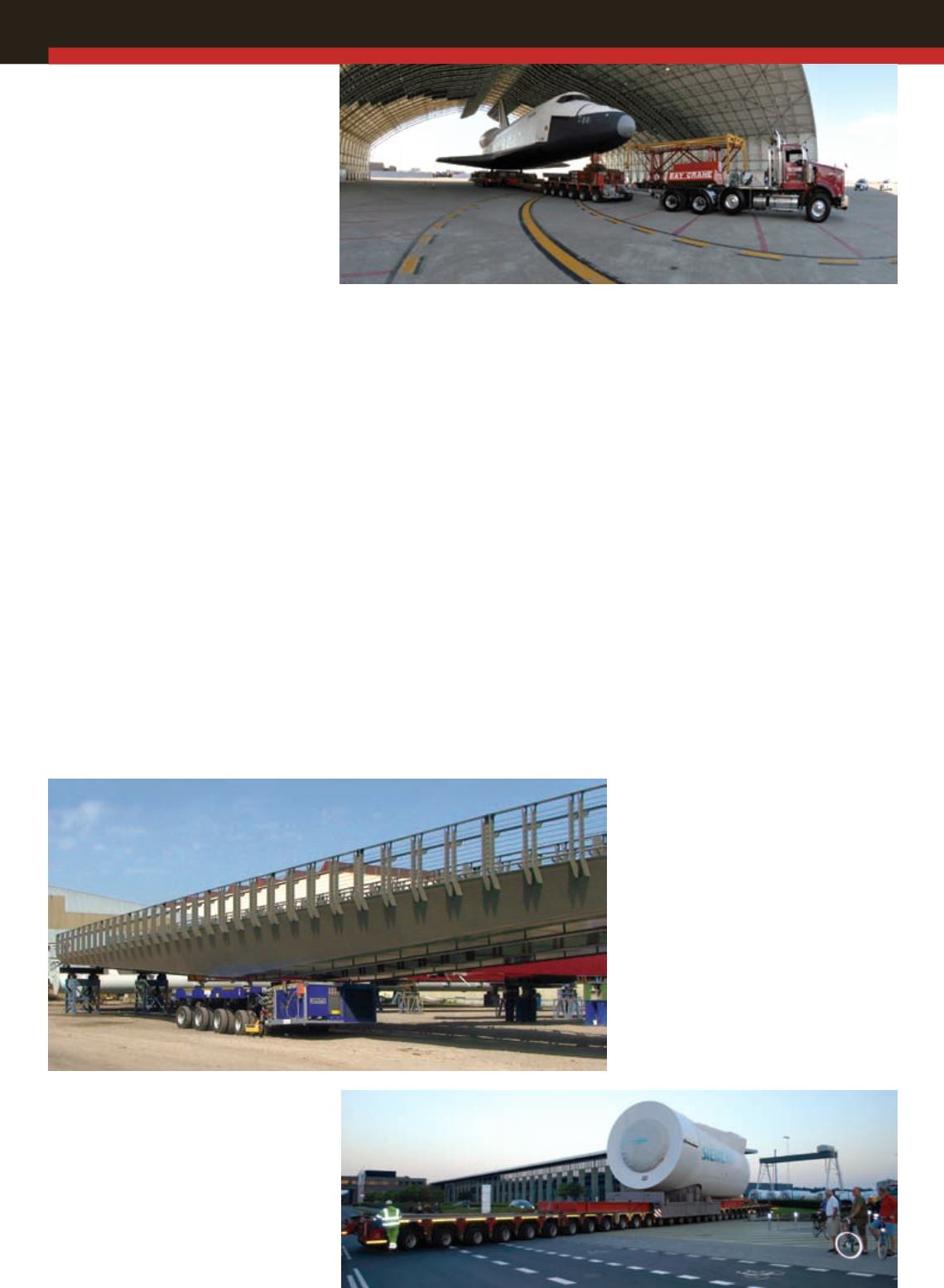

Bay Crane recently purchased 20 axle

lines of Goldhofer SPMT to go with six

lines it already had, for a total of 26 lines.

“SPMTs are probably the most versatile

transport tool on the market,” said Gregg

Barry, vice president, Bay Crane, based in

Long Island City, NY. “The difference is

that these trailers can literally go sideways,

which is quite convenient when doing

rapid bridge replacement [and other jobs].

You can put a very large piece in a very

tight area. The maneuverability they offer

is the key when you have to thread the

needle and are dealing with a very high

center of gravity. The SPMTs all you to do

this with great precision.”

■

Using a Goldhofer system, Bay Crane moved the Space Shuttle Enterprise from

JFK International Airport to the Intrepid Sea, Air and Space Museum in New York.

Mammoet transported one of the world´s

largest nacelles designed by Siemens,

which weighed close to 308 tons tons.

For the transport, Mammoet used 30

InterCombi axle lines from Scheuerle.

The total length of transport, including

two tractor units, was 223 feet. The

nacelle measured 54 x 21 x 22.5 feet.

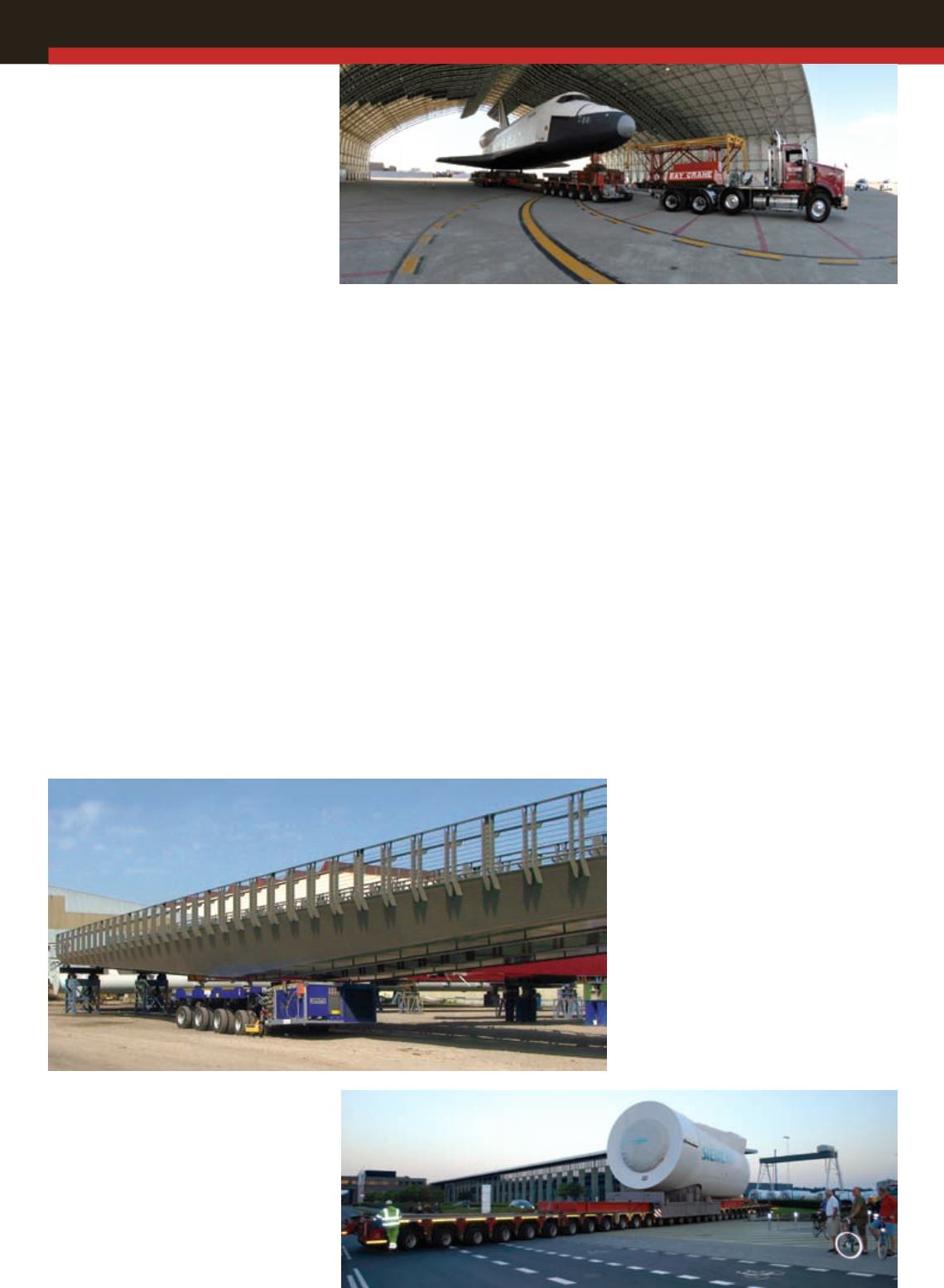

Fagioli uses a Cometto SPMT system

to move a bridge structure.