TELEHANDLERS

>

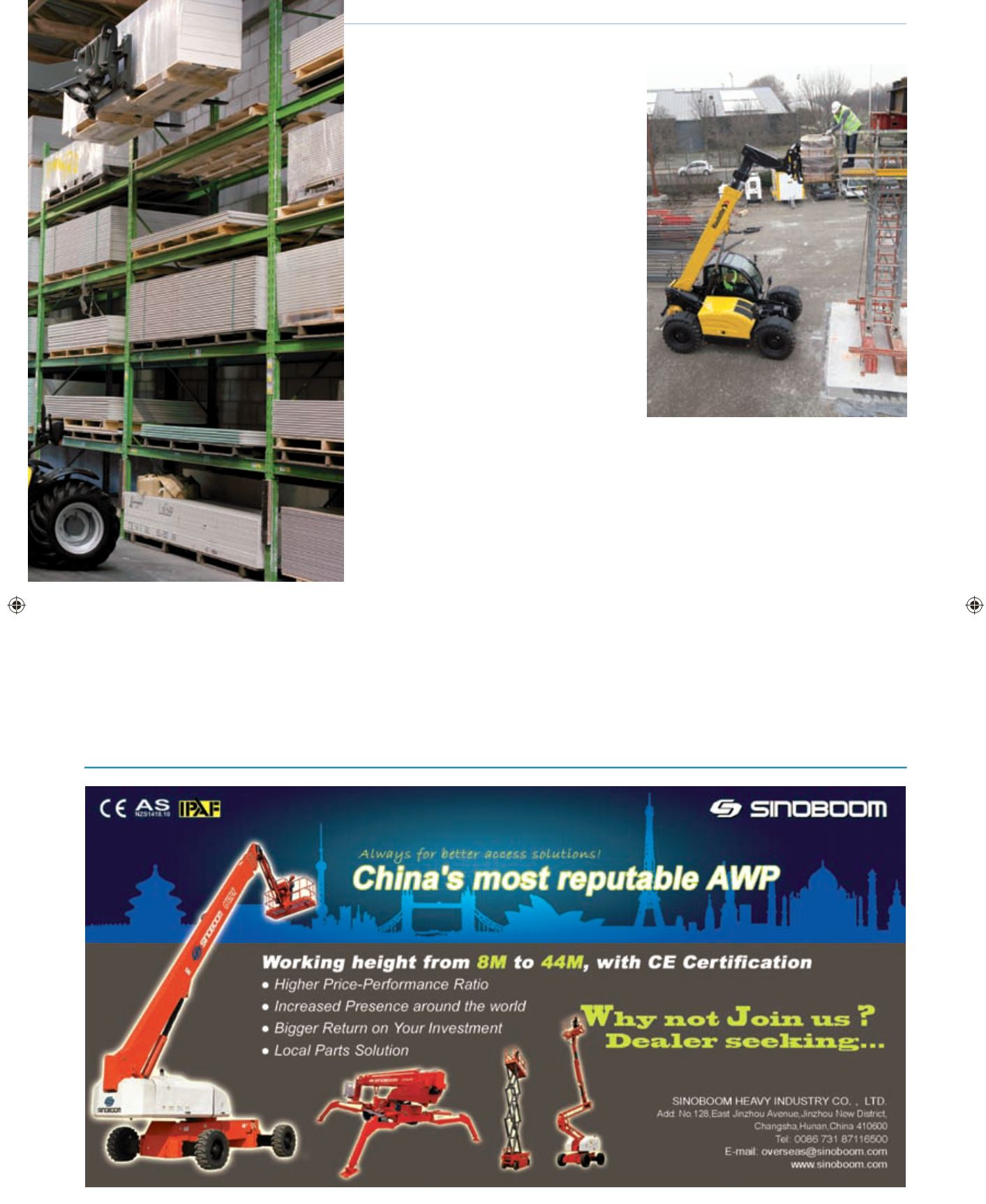

A Wacker Neuson TH412 at

work in a warehouse.

range representing seven models in the 10

m, 14 m and 17 m height. Safety, comfort

and performance are the three key words

attributed to the range, says Stéphane Hubert,

marketing director for Europe and North

Africa.The first of those is represented by

a rear axle locking system and a smart tilt

corrector, standard on the 14 m and 17m

models, to ensure stability. Standard across the

range is Road Mode which prevents any boom

and outrigger actions when you are driving.

Ergonomics were priority of the design

and include a Smart Control 4 in 1 joystick,

electronic and backlit dashboard with

centralised information for the operator.The

load moment indicator is positioned to be

easy to read and includes an automatic cut off

when a tilting risk is detected. Meanwhile, the

driving position is designed to reduce fatigue

with a fully adjustable seat containing shock

absorbers.

The all-important performance is taken

care of through hydrostatic transmission that

distributes continuous power and an inching

pedal for smoothly approaching a structure.

On the 14 m and 17 m models is the Flow

Sharing management system which directs the

hydraulic flow for proportional control.

It is the addition of performance-

enhancing attachments that will shape

the Haulotte models of the future. “We

will keep our position as being a full line

manufacturer within the AWP segments

with a complementary range of telehandlers,

therefore, we will mainly put our attention to

enlarging our range of specific attachments,”

explains Mr Hubert.

Asked if there were any plans to expand

the range upwards, beyond the range-topping

4 tonne capacity, 17 m lifting height of the

HTL 4017, Mr Hubert adds, “This will

be driven by the application requirements

of our customers - we intend to adhere as

much as we can with their needs, even if

it leads to an increase in the load capacity.

Applications trends such as mining or shale

gas extraction for instance both reveal heavy

load requirements.

“We can see big telehandlers mainly

in the US market.These telehandler are

more popular because of the working site

configuration; the user needs to have the best

performance and big capacity of load and

height for major construction projects, for

example,” adds Mr Hubert.

Energy saving

As mentioned, a significant feature of new

telehandler design are energy saving systems

and engines to meet emission regulation.

Merlo showcased its energy saving solutions

at Bauma.

For example, the Panoramic 50.8 is an 8.8

tonne machine that can lift up to 5 tonnes

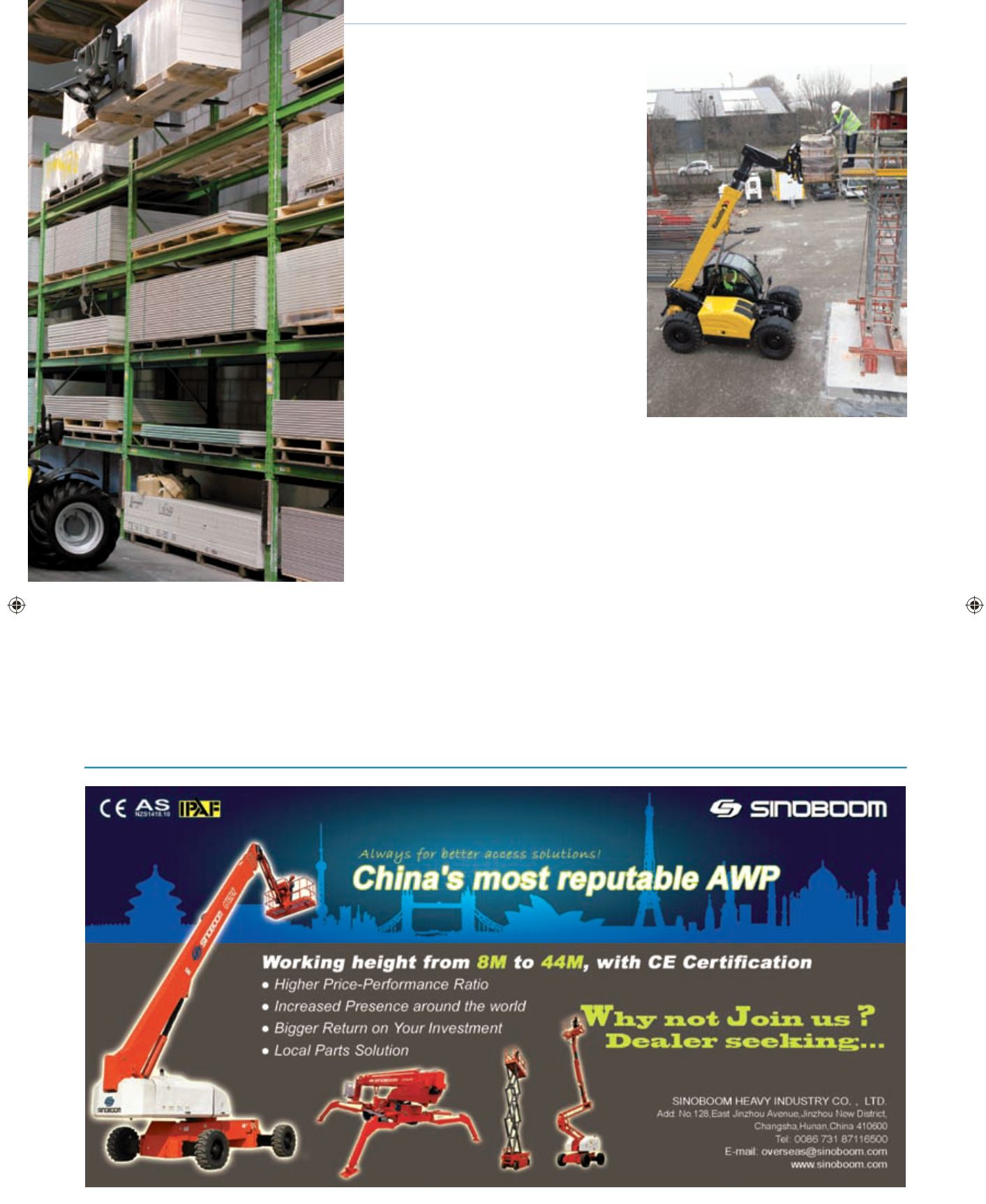

A Haulotte HTL 3510 lifts concrete blocks at a

French construction site.