47

january-february 2015

international

construction

Critical equipment

DRILLING

The Bench Remote can be installed

in a vehicle, trailer or container and all

controls and screens are the same as in the

real cabin on the rig. Communication,

including machine control and safety

functions, takes place over a closedWiFi

network. This makes it independent

of local network infrastructure. If the

network is lost due todistance to thedrill

rig, it will shut down for safety reasons.

Atlas Copco said all its SmartROC

D65drill rigs canbe upgraded for Bench

Remote operation.

A specialist area like drilling is never

really awash with new machines being

launched, but last November’s Bauma

China exhibition saw some interesting

new products unveiled.

AtlasCopco launched its PowerROCT50drill rig at the show,

which was designed and is manufactured at the company’s

Nanjing, China plant.

The company said the aimwhen developing this machine for

quarrying andopenpitmineswas todevelop a robust, powerful,

fuel-efficient rig that could deliver performance in an easy-to-

use, straightforward design. Key features include a new type of

extendable boom, a powerful hydraulic COP 3060 rock drill,

and a choice ofTier 3 orTier 4 engines.

The new boom has been designed for quick and easy

positioning and the company said the high feed force helps

ensure straight holes. Other features include a straightforward

hydraulic and electrical system for easy operation, push-button

controls, aROPS/FOPS certified cabinwith largewindows and

extra vibration dampers, and good ground clearance for easy

tramming in rough terrain.

Product manager York Yang said, “The PowerROCT50 is an

importantmilestone for Atlas Copco inNanjing butmostly for

our customers around the world. We know that this product

>

ground manually drilling the dowel-pin

holes,” said Robert Antoun, of Antoun

Civil Engineering.

Each slab being replaced required 45

holes, so this potentially lengthy process

was cut to about 35 minutes with the

single-gang drill and 20 minutes with

thedouble-gangunit. Another plus point

was that each drill only required one

person to operate it. After two and a half

weeks of an aggressive schedule, working

six nights a week, Antoun Civil Engineering completed the

project ahead of time and under budget.

Stabilisation

Robit is pioneering a ground stabilisation system that uses

fibreglass grout-injection tubes instead of steel ones, having

acquired the patent for the system in 2014. The idea is that

these form an easily-demolished temporary structure, so they

are suitable for reinforcing tunnel faces in between phases of

excavation.

The drilling for the reinforcement work

canbe carried out eitherwith surface rigs

or in tunnels with jumbos and the grout

injection also uses standard equipment.

The company has supplied the system

to the A.T.S. Infratunnel rail project

in Switzerland where there was a risk

of a face collapses. The roof was being

supported with traditionally grouted

steel tubes (forepolling), but 76 mm

diameter fibreglass tubes were drilled up

to21m into the face to reinforce it ahead

of excavation. This meant the tunnel

could advance up to 12 m, with 8 – 9

m of fibreglass tubes still supporting the

face before new 15 m steel tubes had to

be drilled and grouted into the roof.

Robit said the method proved a better

solution than self-drilling anchors, which had been unreliable

on the project and hard to demolish as the tunnel progressed.

It added that its solution alsomet the project’s requirement for

hole straightness, which the anchors did not.

New equipment

New from Atlas Copco is Bench Remote, an operator station

that acts as a full remote control for up to three surface drilling

rigs simultaneously.

The unit was designed to reduce the risk of working close to

unstable and hazardous benches or close to unstable faces.The

Bench Remote operator station can be used up to 100m away

from the drilling area and up to 30m above the rig, as long as

there is a direct line of sight with the drill rig doing thework.

And it is not only a question of safety. Atlas Copco product

manager Mattias Hjerpe said, “The Bench Remote can handle

up to three SmartROCD65 rigs in parallel.Thismultiplies the

operator efficiency andwas made possible by the full drill cycle

automation.”

TwoMinnich dowel pin drillswere

crucial to the success of a high-

pressure project to replace runway and

taxiway slabs at Sydney Airport.

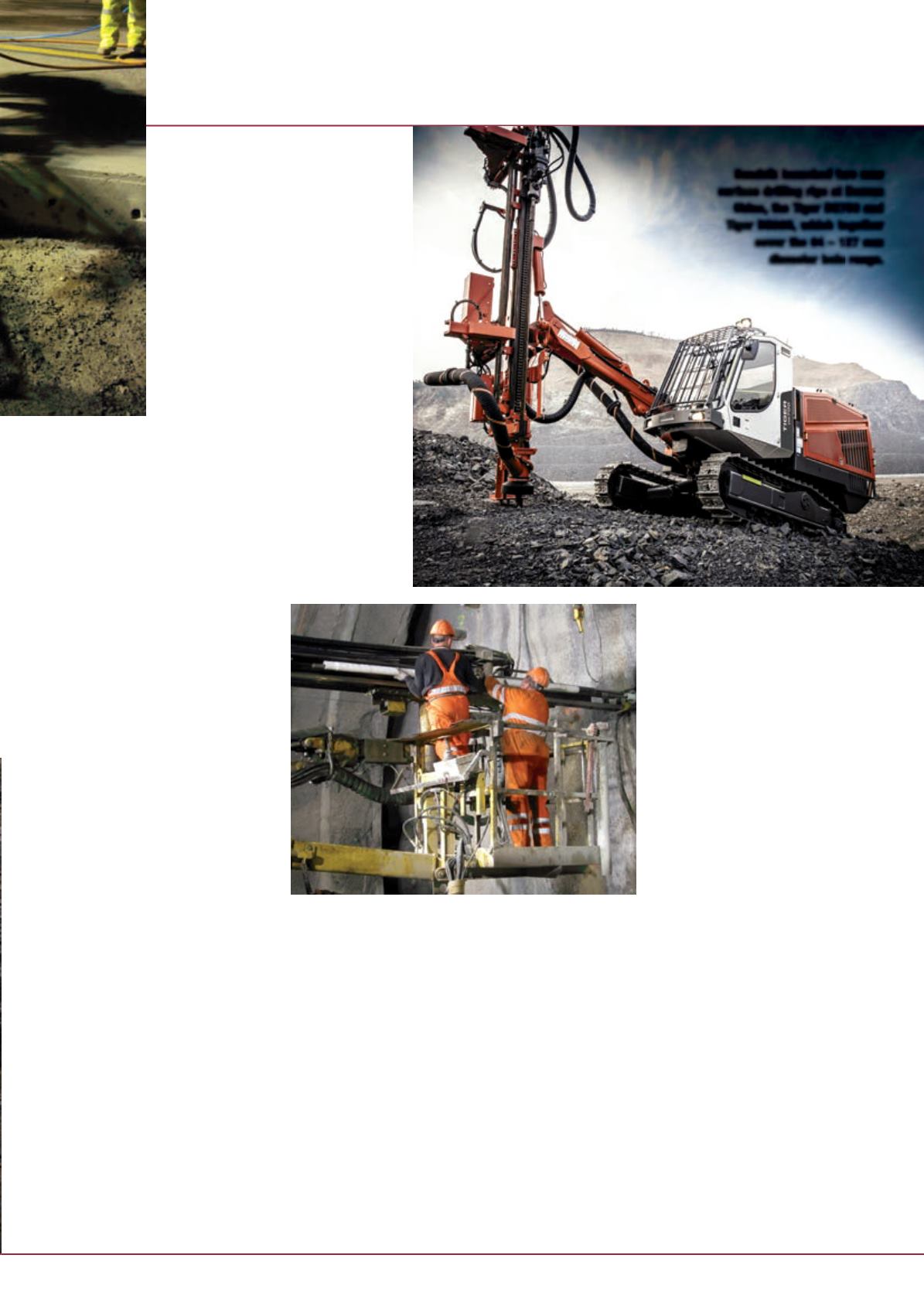

Sandvik launched two new

surface drilling rigs at Bauma

China, the Tiger DG700 and

Tiger DG800, which together

cover the 64 – 127mm

diameter hole range.

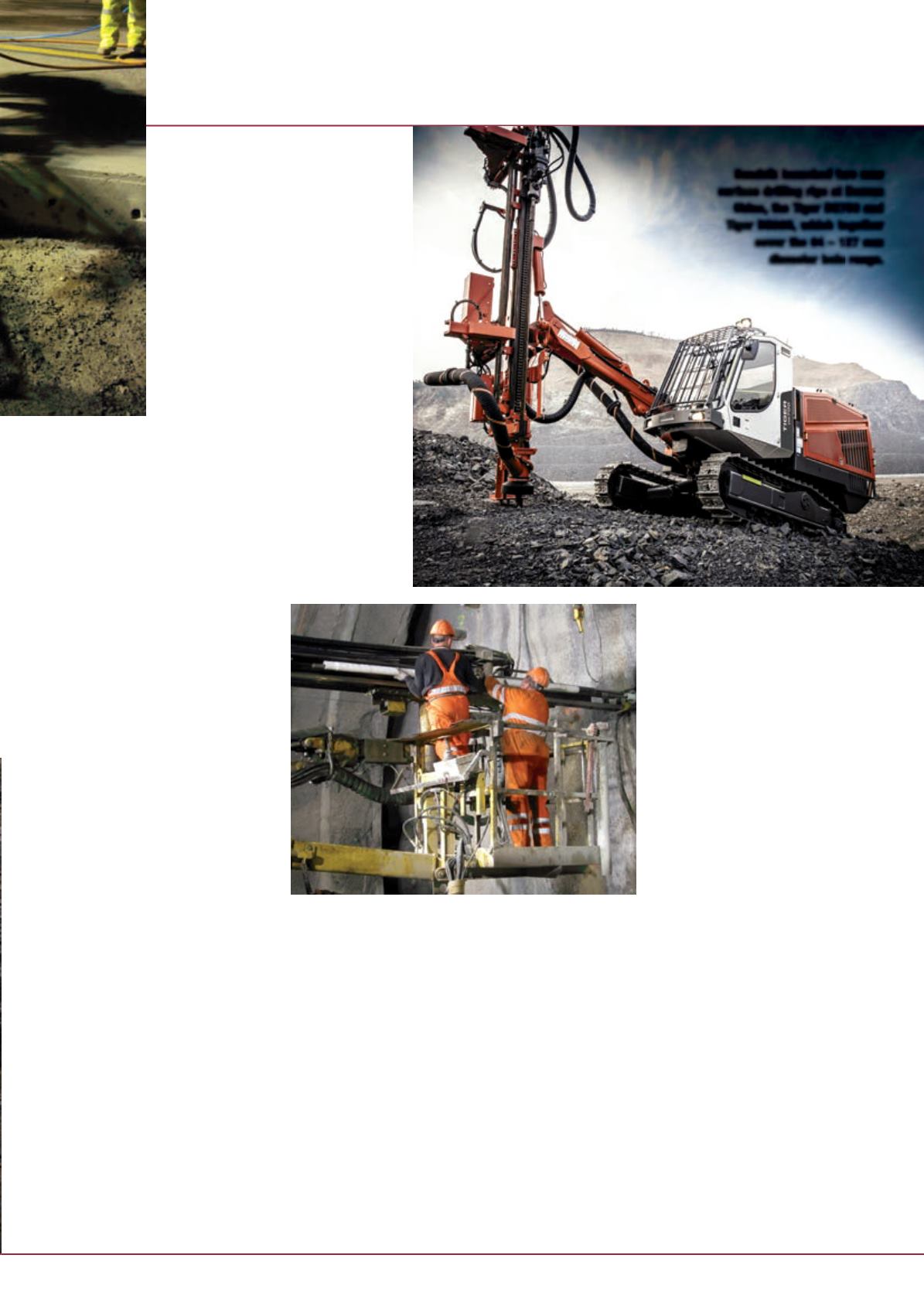

Robit is

pioneering a

temporary tunnel

face support

system using

grouted fibreglass

tubes instead of

steel ones. The

company says its

system is easier

to demolish

as the drive

progresses.