international

construction

january-february 2015

DRILLING

46

Critical equipment

Drilling equipment can often be on the critical path for

construction projects and quarry operations, so reliability

and productivity of thesemachines can also be vital.

Chris Sleight

reports.

Critical

equipment

airport runway reopened eachmorning.

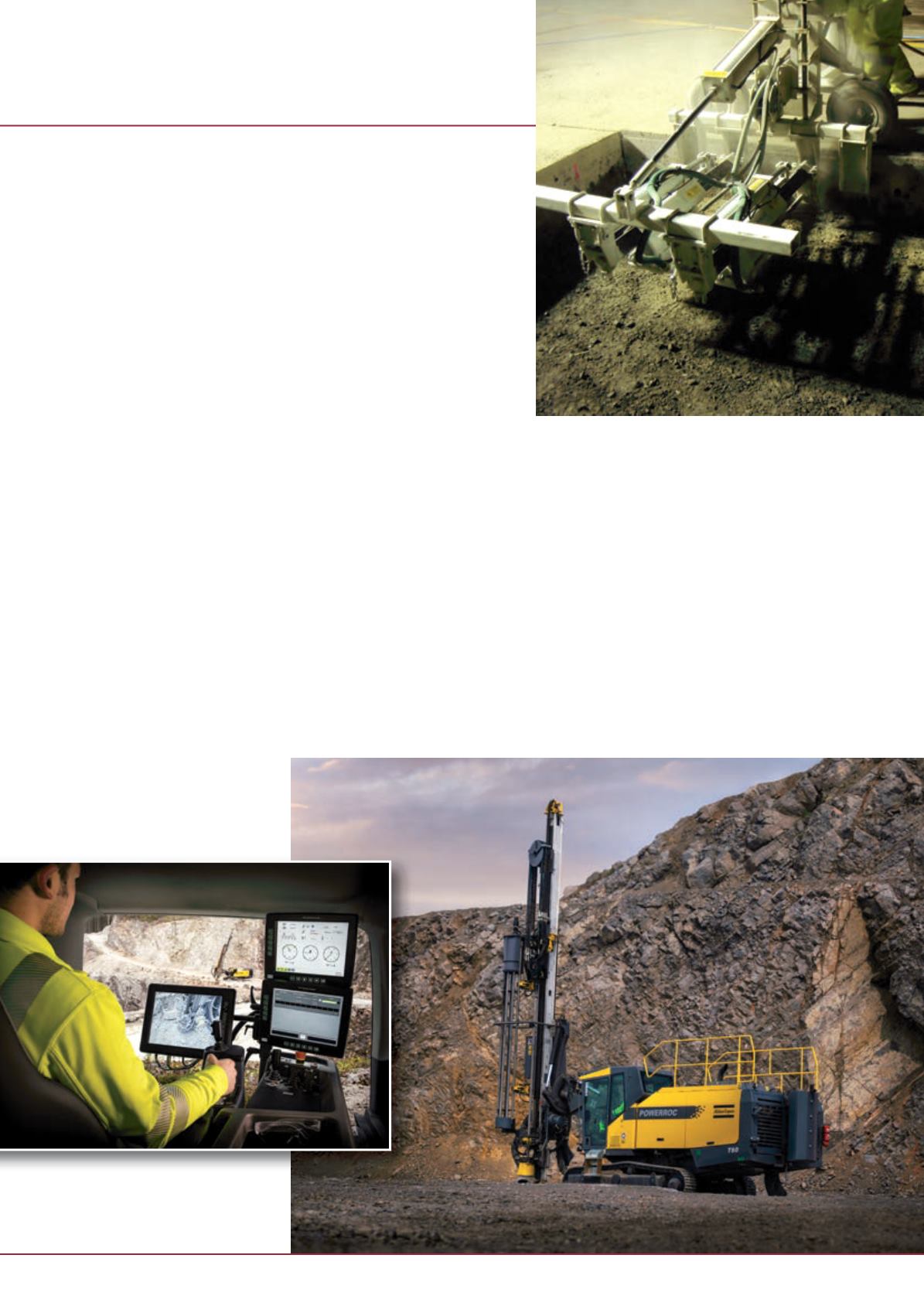

Two key machines were two dowel pin drills fromMinnich

Manufacturing, an A-1C-48, and an A-2C-48, equipped with

an optional dust collection system.They were used for drilling

the 36mmdiameter holes in the existing slabs for dowel bars to

be inserted before pouring the fresh concrete.

TherecommendationthatMinnichdrillswouldbetherighttool

for the job camedown from themanagement team atdistributor

Volumetric, which has worked with Minnich Manufacturing

for some five years.This was founded on impressive service and

support from theMinnichManufacturing sales teamwhich has

seen the relationship blossom to a point where Volumetric is

the exclusiveMinnich equipment distributor for all ofAustralia.

“We were able to drill the holes that we needed in existing

slabs in about 45 seconds per hole for the single drill unit, and

twoholes in the same amount of time for the double-gang unit.

Not only were theMinnich drills efficient, but safety also came

into play for us – we really didn’t want our guys down on the

D

rillingequipment and its applicationsmightbeviewedas

something of a niche activity in the construction sector.

However, thesemachines can often be a vital link in the

chain on construction projects and in aggregates extraction.

For example, repairing sections of the 1950s-era runway and

taxiway at Sydney, Australia airport was a challenge for Antoun

Civil Engineering for a number of reasons.The airport handles

300,000 aircraft movements and 37 million travellers per

day, and although the repairs were urgent, replacement of the

damaged slab areas could only be carried out during the normal

runway shutdownperiodof 11.00pm–4.30 am eachnight.Of

course, should the runwaybeunable to reopenon time, Antoun

Civil Engineering would face massive

penalties.

Efficient equipmentwas key toworking

around this time constrain on the cycle

of demolition, removal, pouring and

achieving structural strength before the

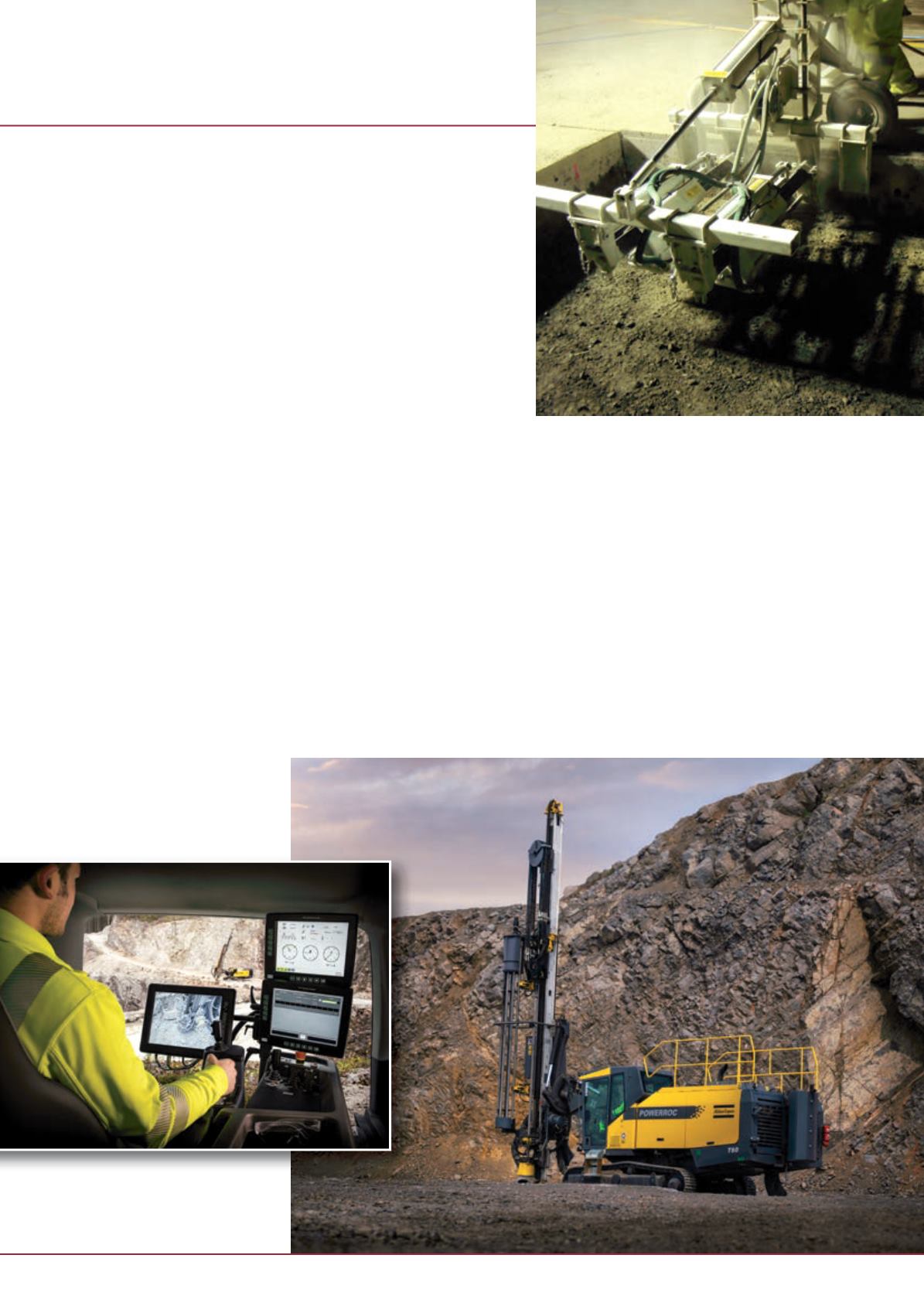

Bench remote is a new remote

controlled operator station fromAtlas

Copcowhich can remotely control up to

three surface rigs at once.

The PowerROC

T50 is a new

surface rig

designed and

built by Atlas

Copco in China.

It is designed to

be a simple, yet

powerful and

robust machine.