35

december 2014

international

construction

Efficiency drive

CRUSHING&SCREENING

Nordberg C106 single toggle jaw crusher designated as the

Liugong LM J106.Themachine was joined on the stand by the

LM S48 tracked screen.

Both are designed for the Chinese market, with the crusher

featuring a diesel delivering 194 kW certified to Tier II and

the latter, weighing in at 32 tonnes, featuring a Tier III engine

delivering 86 kW.

According to the company, they are designed for crushinghard

stone and recovering building materials in quarrying, mining,

cement,municipal road and bridge construction.

Crushers

Precision and efficiency are key to Irock’s latest crusher, theTC-

20, whichmade its debut at the Conexpo industry event in Las

Vegas earlier this year.

Combining a larger feeder and a high performance four-bar

impactor, the company said it produces a uniform, cubical

product, with hydraulically adjustable aprons providing added

control over sizing.

According to Irock, its latest machine has the versatility to

process soft to medium rock, recycled concrete and recycled

asphalt.

The crusher’s rotor measures 40 inches

(1,016 mm) by 56 inches (1,422 mm)

and can process a variety of materials up

to24 inches (610mm) indiameter.A440

hp (328 kW) Caterpillar C-13 ACERT

Tier 3 engine powers themachine, which

canprocess up to 500 tonnes per hour.

The tracked crusher features a

fixed, Hardox steel hopper offering a

11.4 m

3

capacity. It is paired with a 52

inch (1,320mm) vibrating grizzly feeder,

which has three quarter inch (19 mm)

liners on the pan and side walls. The

feeder is up to 3 feet (914 mm) longer

than comparableunits,making it possible

to feedmaterial with a largewheel loader.

Consistent product development in

terms of flexible design and operational

readiness is an approach that Rockster

says it has applied to its range of crushers

–with its R1100DSno exception.

Featuring its multi-function display the

machine’s crushing gap can be adjusted

fully hydraulically and continuously, so

the final material can be defined simply

and easily, aiding precision of screening

curves.

The conveying velocity continuously

adapts the crusher load and the operating

pressure of the main conveyor, which

prevents overload and downtimes. If

necessary, the vibrating feeder can be

infinitely controlledmanually via the remote control.

Competingwithharsh climates is often a key consideration for

equipment for the crushing and screening sector.

One exampleof performanceunder testing conditions isSBM’s

STE 100.65.T combined with its Remax 132 Eco operating in

theTschita region of Siberia.

The mobile track-mounted primary and secondary crushing

unit, consistingof a jaw crusher and an impact crusher, is loaded

herewith especiallyhard and toughgabbrobasaltwith a feed size

of up to 600 mm. With a throughput of some 200 tonnes an

hour, a final grain size of 0-45mmwas achieved.

>

Mobile solution

Sa

ndvik

t

ra

ck

ed j

a

w

cru

s

h

er fo

r new

US q

u

a

rry

W

h

enUS co

mp

a

ny Ca

nyo

nRo

ck

inNo

rt

h

Ca

l

ifo

rnia

,

a

cq

u

ired a

s

eco

nd q

u

a

rry t

h

is

yea

r,

t

h

e bu

s

ines

s

fo

u

nd it

req

u

ired a

p

rima

ry cru

s

h

er t

h

a

t

w

o

u

l

d be a

bl

e t

o

h

a

ndl

e

h

ea

vy du

t

y q

u

a

rrying

a

p

p

l

ica

t

io

ns

ea

s

il

y.

T

h

e s

o

l

u

t

io

n w

a

s

p

ro

vided in t

h

e fo

rm o

f

a

Sa

ndvik

Co

ns

t

ru

ct

io

nUJ

440i t

ra

ck

ed j

a

w

cru

s

h

er.

In 2014Ca

nyo

nRo

ck

a

cq

u

ired it

s

s

eco

nd q

u

a

rry.

T

h

is

p

ro

videdma

t

eria

l

fo

r rip

ra

p

,

a

nd

s

t

o

ne,

fo

r t

h

e So

no

ma

–M

a

rin A

r ea

Ra

il

T

ra

ns

it

p

ro

j

ect

-

a

7

0mil

e (

113

k

m)

ra

il

a

nd bik

ew

a

y

w

h

ich

cro

s

s

es

t

h

e reg

io

n.

T

h

e fa

mil

y o

w

ned co

mp

a

ny’

s

rep

u

t

a

t

io

n fo

r o

p

era

t

ing

w

it

h

o

p

t

ima

l

efficiency w

a

s

a

t

s

t

a

k

e,

s

o

it

w

a

s

es

s

ent

ia

l

t

h

e bu

s

ines

s

ch

o

s

e t

h

e rig

h

t

p

rima

ry cru

s

h

er -

o

ne t

h

a

t

co

u

l

d h

a

ndl

e

h

ea

vy du

t

y q

u

a

rrying

a

p

p

l

ica

t

io

ns

ea

s

il

y.

Ca

nyo

nRo

ck

co

-

o

w

ner J

o

na

t

h

a

n T

ra

p

p

e s

a

id,

“

T

h

eUJ

440i is

a

s

t

ep

-

u

p

.

T

h

e ch

a

s

s

is

,

t

h

e

fra

me,

t

h

e bel

t

-

everyt

h

ing

is

s

t

u

rdier.

W

e w

ere l

o

o

k

ing

fo

r s

o

met

h

ing

t

h

a

t

w

o

u

l

d l

a

s

t

a

l

o

t

l

o

ng

er t

h

a

n a

reg

u

l

a

r co

nt

ra

ct

o

r’

s

p

rima

ry j

a

w

,

s

o

met

h

ing

t

h

a

t

w

o

u

l

d ru

n w

el

l

a

nd l

a

s

t

fo

r

15

-

20 yea

rs

.

”

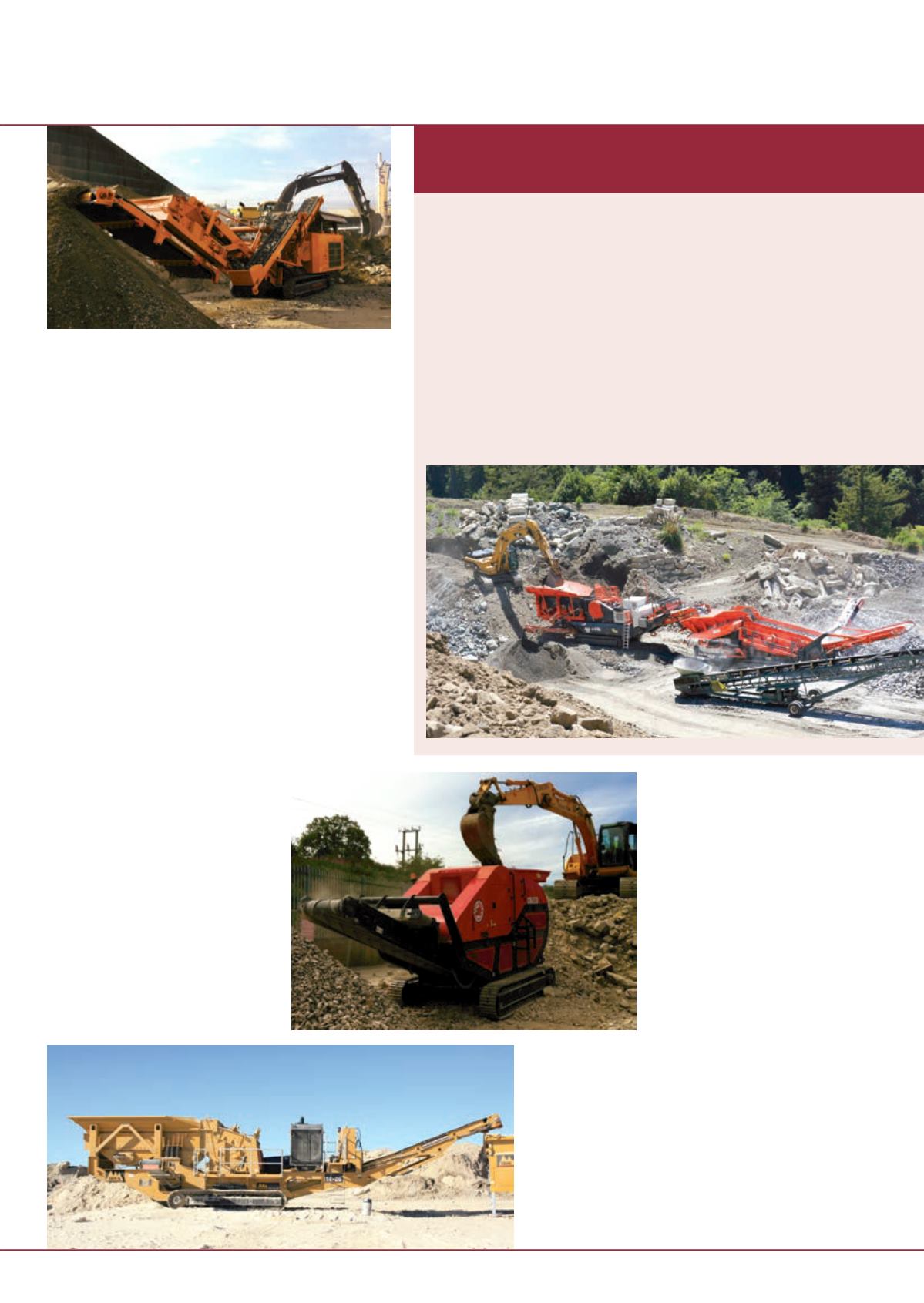

Rockster R110DS offers a flexible design, according to its

developers.

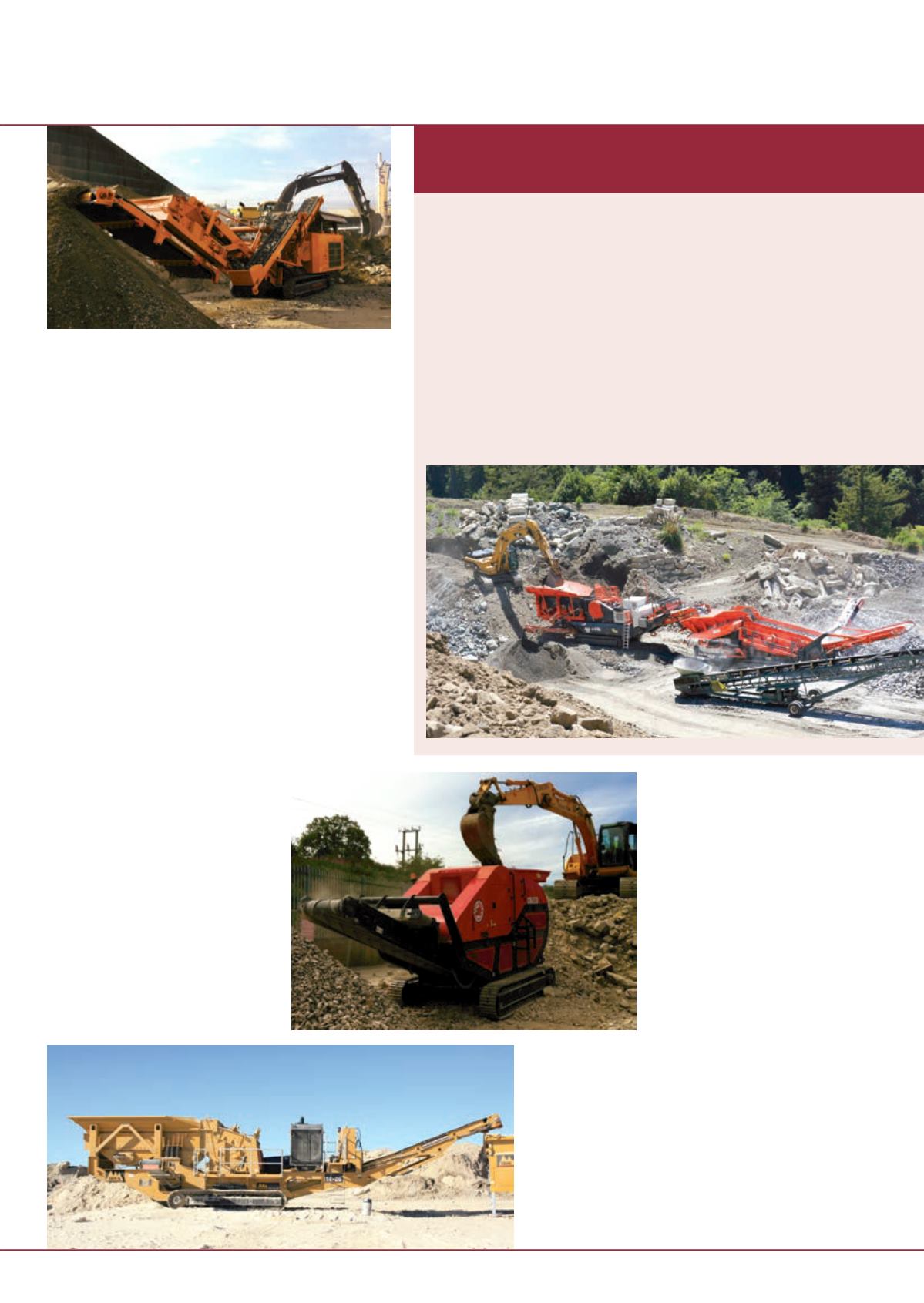

IROCK’s TC-20 crusher in action, after

its release this year in the US.

ARed Rhino crusher being

put through its paces.