31

december 2014

international

construction

Efficiency drive

CRUSHING&SCREENING

when used with an accompanying software package to further

improve efficiency levels through greater automation.

The company has also developedwear-protection lining for its

products, which it has said can extend the lifetime of equipment

by up to 25%.

Working environments are also improved through Sandvik’s

focus on dust encapsulation features built into its crushing and

screening products.

Mr Delbrant said, “We have seen an increased global focus

on environmental health and safety. Together with the feedback

we receive from our customers, we have developed several new

products (including the CH500 series of cone crushers) and

made improvements to our existing products in order to reduce

our environmental footprint, improve safety and ergonomics for

the users, better performance and quality of the end product,

>

A

chieving greater levels of efficiency and operating

reliability remain among the key drivers in the crushing

and screening equipment sector.

Keeping pace with new developments in technology including

enginedesign thathas seen stricterStage IV/Tier4final emissions

limits introduced this year in theUS andEurope has also posed

its own set of challenges.

So too has the on-going industry need to develop ranges of

mobile equipment that are capable of operating in some of the

world’smost inaccessible locations.

As Mikael Delbrant, vice president of Sandvik’s crushing and

screening division explained, another core factor has been in

devising products that respond to expanding health and safety

regulations.

This has included environmental impact analysis of Sandvik’s

overall business practices, including developing emissions-

conscious equipment and improving its recycling policy.

Among its technology advances, this year has seen the

introductionof anASR (automatic setting regulation) automated

control system for its cone crushers.

This core development protects the equipment from overload

Grea

t

er p

r o

du

ct

ivit

y w

it

h

crush

ing

a

nd s

cr eening

equ

ip

m ent

is

a

n a

rea

wh

e re new

t

ech

no

lo

g

y ca

n ha

ve a

bea

ring,

a

nd t

h

e re is

a

lso

a

drive fo

r g

rea

t

er s

a

fet

y a

nd

enviro

nment

a

l

p

e rfo

rma

nce.

Neill Barston

repo

rt

s.

Efficiency drive

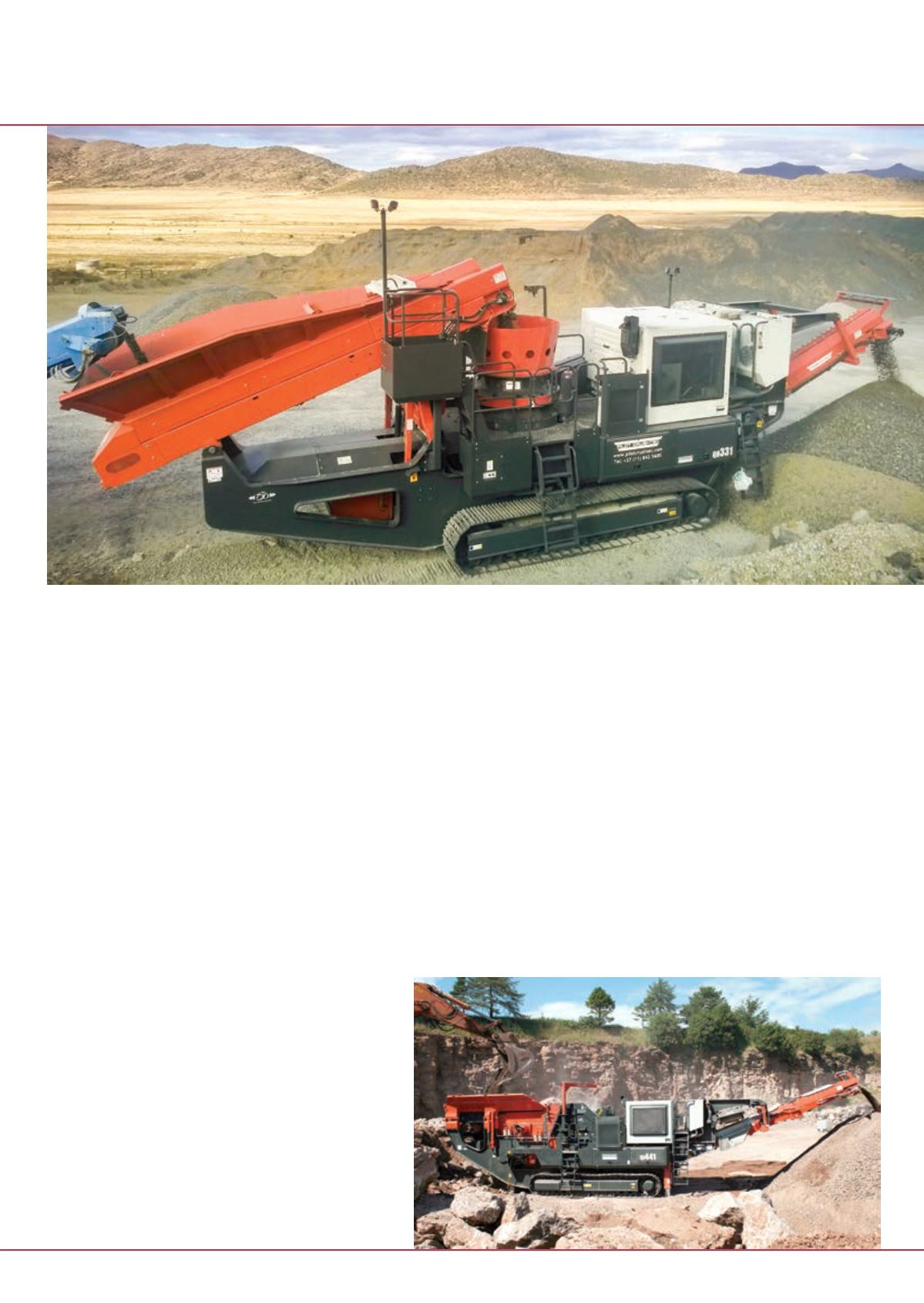

A QH331 Sandvik Construction trackedmobile cone

crusher ismaking light work of volcanic rock in

South Africa, for a road construction project in

Eastern Capewith distributor Pilot Crushtec.

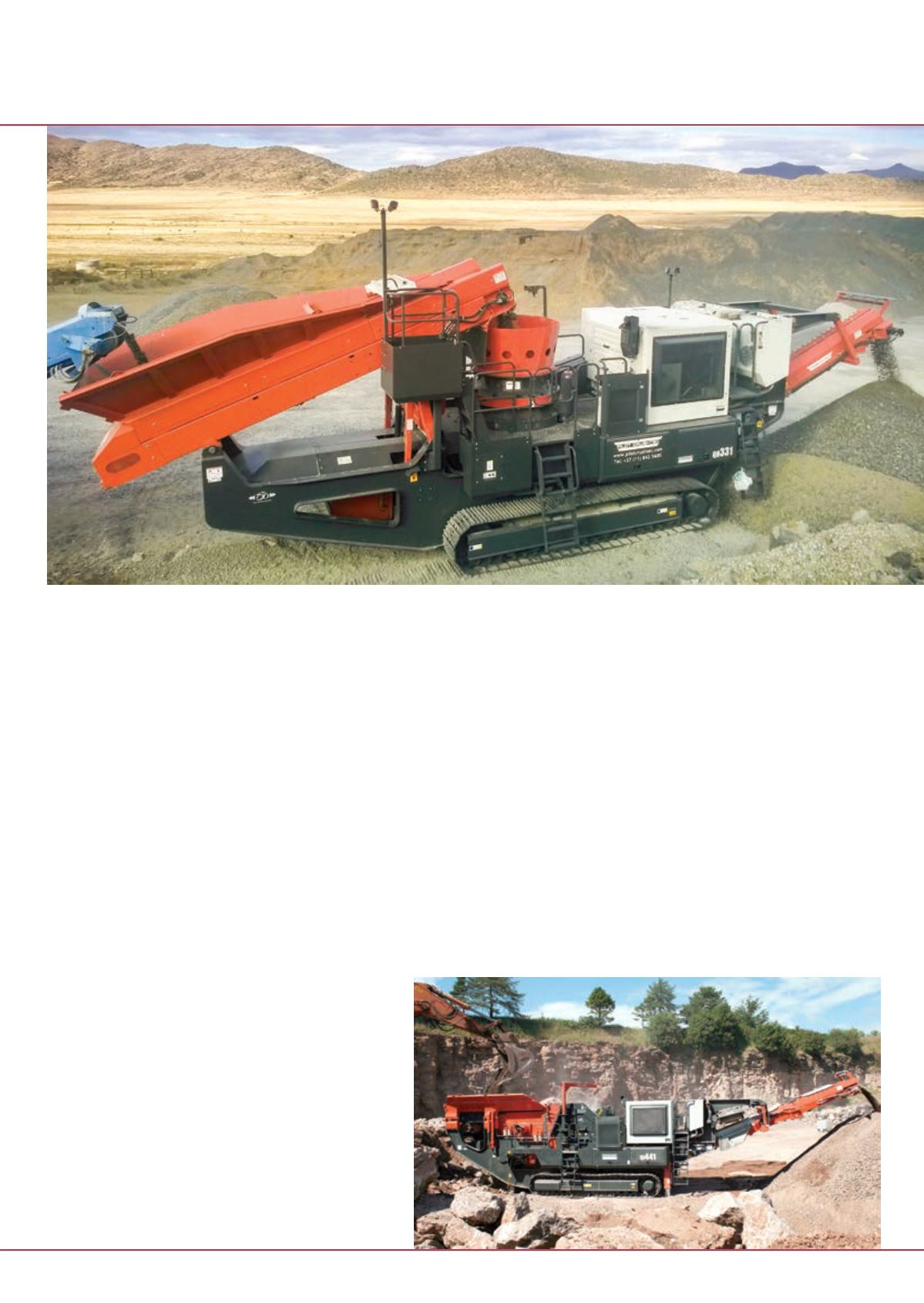

Sandvik’s Q1441

mobile tracked

crusher was on

show at Bauma

China.