INTERNATIONAL ANDSPECIALIZED TRANSPORT

■

MARCH 2015

40

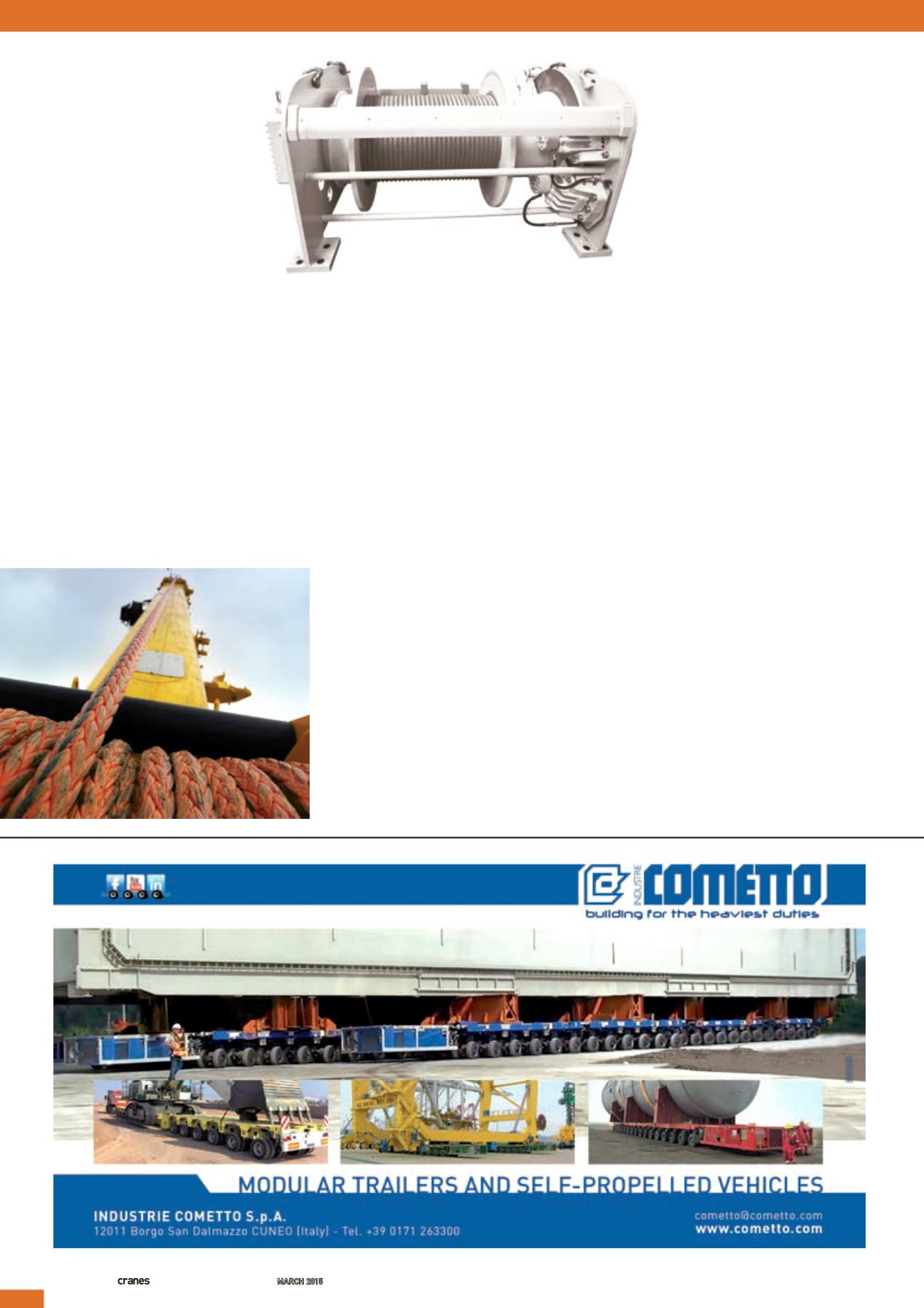

The215horsepower-rated electric

winchaccommodatesup to

580mof ropeon thedrumand,

whenworking in single fall, this

hoistingunit can lift loadsof

2.3 tonnes at up to256m

perminute.

FromGermany-basedmechanical

engineeringmanufacturerZollern

is an electricallydriven ropewinch.

Thewinchwasoriginallydesigned

for adrawworksona truckmounted

onshoredrillingdevice and isdesigned

withanasynchronousmotor anda

speciallydesigneddriveunit andgearbox.

Toaccommodateworkingon future

drilling rigs,whichwill offerdrillingdepths

of 5,000m, themotor andplanetarygear

havebeenhoused inside the ropedrum.

HolgerGraf, Zollernmarine technology

segmentmanager, says, “ThenewZollern

compact electricwinch canbeused in

each typeof crane, including shipboard

cranesorbulkmaterial handling cranes.

Inprinciple it is an electricallydriven

cranewinchwithan electricmotor that is

patented, is alsoon themodel. To

reducewearon themainwire rope,

twohydraulic cylinders allow for

the adjustment of the liftingheight

withoutmoving thedrumof the

hoistingwinch.

From cranemanufacturerPalfinger

is the rope tension control (RTC) and

the synchronised rope control (SRC)

system. TheRTC is anautomatic rope

tensioningdevice thatmakes it easier

to foldandunfold the cranewith the

rope reeved inand the fly jibmounted,

themanufacturer says. The system

automaticallyadjusts the rope length to

match themovementsof the crane.

Similar to theRTC, theSRC system

automaticallyadjusts the rope lengthand

maintains a constant distancebetween

thepulleyheadand thehookblock

duringoperationof the ropewinch. This

allows loads tobe traversedhorizontally

at a constant heightwithout theoperator

having toadjust the ropewinch. Sensors in

the rollerheadareused toavoid collisions

between thehookblockand thepulley

head. The system sends signalsdirectly to

thePaltronic150, a spokesperson explains.

“If theSRC is activated, it automatically

makes thenecessaryadjustments to ensure

that thedistancebetween thepulleyhead

and thehookblock remains constant

duringany cranemovements that lengthen

or shorten the rope length. If theknuckle

boomor fly-jib is lowered, theSRCagain

adjusts the ropewinch tokeepa constant

distancebetween the lowerblockand the

rollerhead,” a spokesperson fromPalfinger

adds. The systems are available for SH

cranemodels (SRC fromPK10002SHand

RTC fromPK27002SH).

■

SamsonKZTM100 synthetic hoist rope

incorporated inside thedrum.”

The340kilowattmotor isoil-cooled

andhasbeenproduced in-house, ashas

the two-stageplanetarygear.Anadditional

hydraulic emergencydrivewith two spur

gear stageshasbeen installed toprevent

damage if themaindriveunitwere to fail.

Thewinchhas a cablepull on thedrum

of 160kNandamaximum speedof 600

metresperminute. It hasbeenapproved

byGerman technical inspectionauthority

TechnischerÜber-wachungsverein (TÜV).

Forwork in explosive environments, all

heat-generating componentshavebeen

enclosedandbraking temperaturesdonot

exceed200degreesCelsius.

The latestwinchdesign fromLiebherr

ison the300 tonne capacityLiebherrRL-K

7500 subseaknuckleboom crane. It can

handle loadsdown toawaterdepthof

3,600metres and it has a ropediameterof

82mm. To ensureoptimised ropeguidance,

the cranehas apatentedhorizontalwinch

shifting system,which, according to

Liebherr, guarantees the ideal fleet angleof

the ropeunder all load conditions inboth

hoistingand loweringoperations.Avertical

winch frame lifting system,which is also

TheZollernelectrically driven

ropewinch

ROPES&WINCHES