INTERNATIONAL ANDSPECIALIZED TRANSPORT

■

MARCH 2015

38

Wyoming, Texas andSouthAfrica. The

results showed that PowerMaxPlus lasted

more than twice as longas theirprevious

drag ropes, increasing the timebetween

rope replacements, themanufacturer

says. PowerMaxPlus ispart ofUnion’s

PowerMaxPlus familyof products fordrag

ropeswhichalso includesPowerMaxPFV

Plus, andPowerMaxMDPlus.

Industry standards

Despite the risingpopularityof synthetic

materials, there are few standards for

syntheticproducts, especiallywhen

compared to steel ropes andassociated

accessories. Forwire ropes,manufacturers

have tomeet the

EN12999

standard for

cranes. Inaddition, cranemanufacturers

include information regarding safety checks

anddiscard criteriaonwire ropes and

winches.CranemanufacturerHiab, for

example, has included information in the

instructionmanual regardingdaily checks.

“If awire isdamaged then thedriver should

contact anauthorised service centre,”

LottaClausen,Hiabvicepresident of

communications, adds. “Inaddition, if any

of thewinchesdonotworkproperly the

driver gets an errormessagevia theSpace

security system.”

CranemanufacturerTadanoalso

includes informationondiscard criteria

inoperationmanuals. “We clarify the

criteriaofwire rope replacement at daily

andmonthly inspectionsofwire ropes

forbreaking,wear and corrosion, details

ofwhich canbe found in theoperation

manual,” a spokesperson fromTadano says.

“Wedon’t adopt syntheticwire ropeyet;

however,we are researchingand reviewing

syntheticwire rope to

innovate it in

the future.”

Manufacturer

FibreMaxhas its

owndiscard criteria

inplace, asWilcovan

Zonneveld explains, “We

have inspectionanddiscard

criteriaonhand forour

pendantsduring installationor

before transport and storage.Our

syntheticpendants areprotected

fromdamage and chafebymultiple

layersof polyesterwebbingmaterial.

Theouter layer is supplied inblackas a

standard colourbut canbe supplied in the

colourof the crane aswell, dependingon

customer specifications. The inner cover

has a contrasting colour (generally red)

which indicates that thependant needs

tobe inspectedor repairedwhenever this

colour is visible.”

For synthetic ropes,manufacturers are

looking todevelop criteria similar to the

steel ropediscard

ISO4309:2010Cranes,

wire ropes, careandmaintenance, inspection

anddiscard

.Manufacturerof steelwire

and synthetic ropes, Bridon, for example,

is involvedwithanumberof projectswith

theobjectiveof developingperformance

related criteria for synthetics. Tohelp

increase industryknowledge, the company

uses theBridonTechnologyCentre (BTC)

for testingboth synthetic and steel ropes

indevelopment.

JohnChurchfield, technologydirector

forBridon, says, “Advances arebeingmade

in syntheticmaterial performance, but

it remainsquite sensitive tomechanical

damage. Sharing learning from field trials

ofmultilayer spooled, fully synthetic

deep-sea trawlwarps canactively inform

development of synthetic crane rope.

Inaddition, demands and extensive

experienceof the challengesof specialist

high capacity cranes can identify the

performance requirements and limitations

of such ropes.”

Winch requirements

Performance requirements and the effects

of spoolingare also influencing thedesign

and functionofwinches. Tomeet the latest

buildingdesigns that fall into the ‘supertall’

categoryof skyscrapers (buildings above

380m),winchesprimarilyneed tooffer

high line speeds andhave the ability to

spool hundredsofmetresof ropeontoa

drum.One example tomeet thesedemands

is the215LBR120winch fromManitowoc.

ROPES&WINCHES

introductionof theManitowocKZTM100

synthetic rope,whichhas sincebeen

introducedonallGrove rough terrainand

truckmounted cranes (excluding the

RT9150andTMS9000).The synthetic

fibre is suppliedbyDSMDyneema.

“TheKZTM100Synthetic rope

is 80% lighter thanwire rope and

boasts torqueneutral construction

that eliminates load spinand cabling,” a

spokesperson fromManitowoc says. “The

newhoistmaterial alsomakes for easy

handling, reevingand installationas it

reduces kinking, bird caginganddamage

fromother typesof cable-spooling issues.

TheKZTM100 is corrosion resistant,

requiresno lubrication, isdurable and easy

toworkwith.”

Syntheticmaterialshave alsobeenused

in thenewUnionPowerMaxPlus steel

drag rope from ropemanufacturerWireCo.

“Thewire ropehasplastic enhancement

that protects the rope core frommaterial

intrusionand fatigue,” aWireCo

spokesperson says. “It alsohas improved

abrasion resistance andan increased

service life.”

TheUnionPowerMaxPlus ropehas

undergone field trials at coalmines in

FibreMax cranependants are custommadeand

areavailable ina rangeof breaking strengths

and lengthsup 150metres

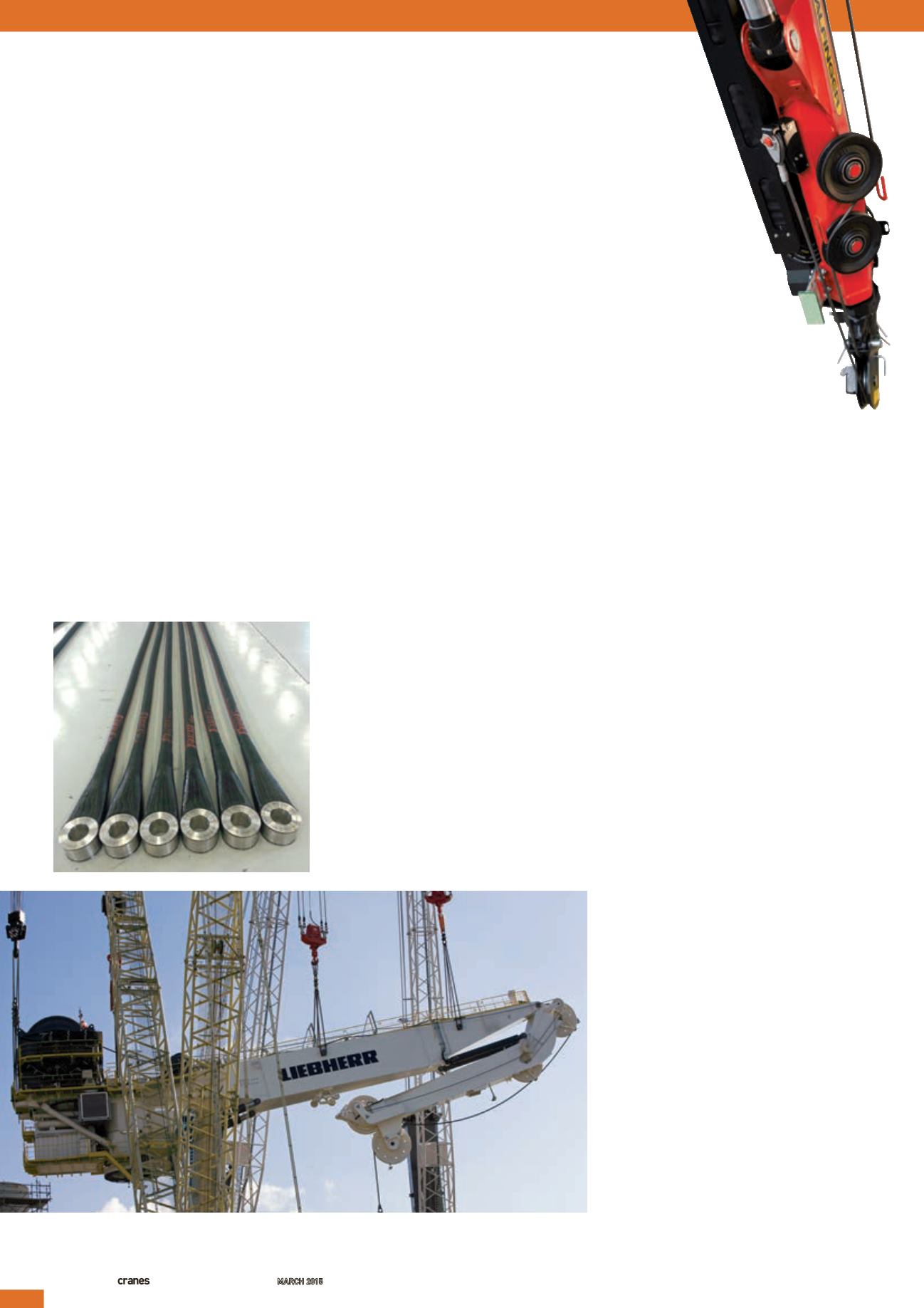

TheLiebherrRL-K7500has apatentedhorizontal winch shifting system toguarantee the ideal fleet

angleof the rope. A vertical winch frame lifting system is alsoon themodel

ThePalfinger rope

tension control

(RTC) system

>