35

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

OCTOBER 20

13

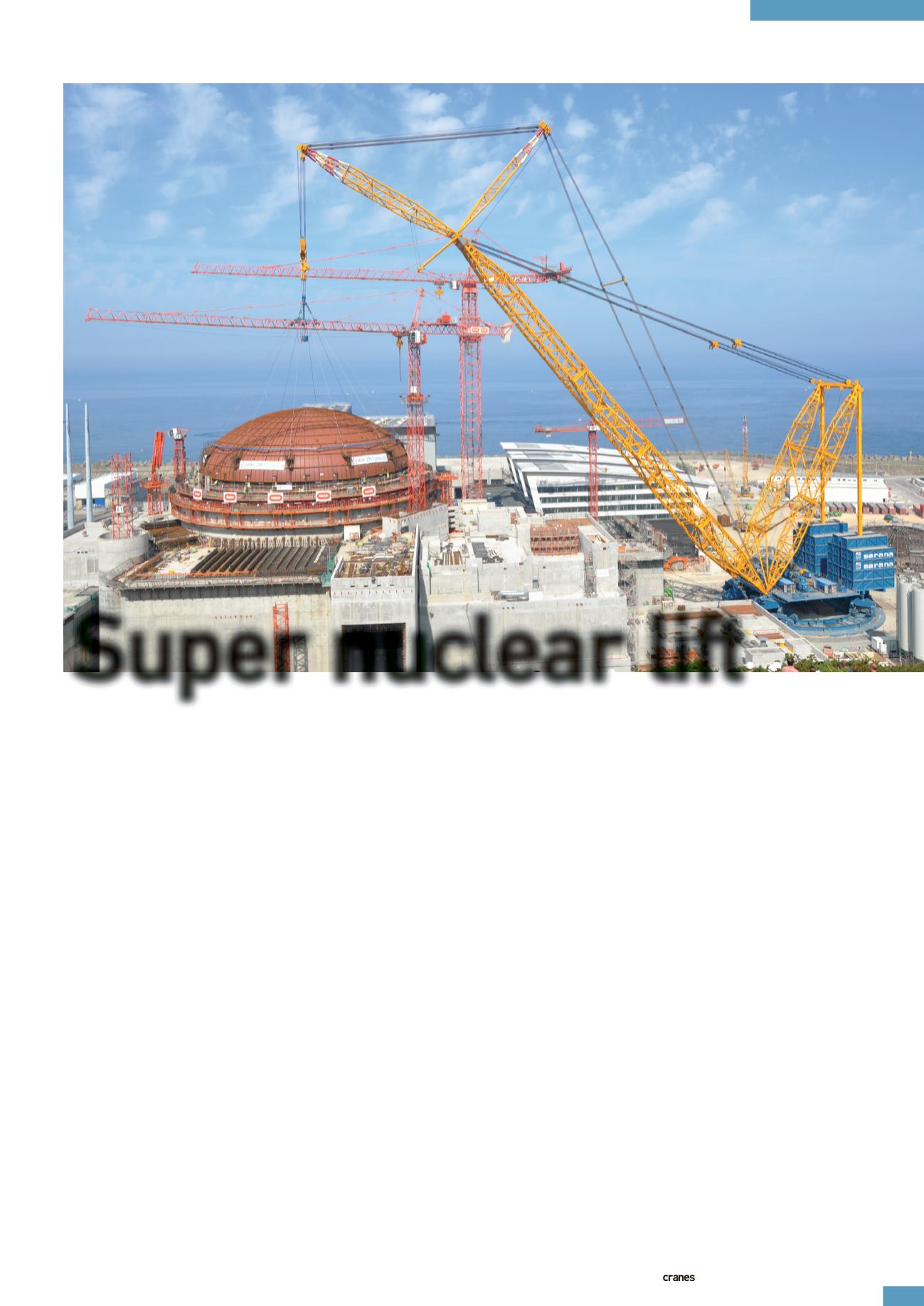

International lifting and transport specialist Sarens from Belgium used its 3,200 tonne

capacity SGC-120 super heavy lift crane for a lift weighing hundreds of tonnes – at well

over 100 metres radius – on a nuclear power plant project in France.

IC

reports

example, rock and sand, once at the jobsite.

This method of creating counterweight

without having to transport it is used to

reduce transport weight and save money.

With the crane components delivered

to the job site it took six weeks to assemble

the crane. The SGC-120 was assembled

in a space measuring 50 x 200 m. It has

a base of 44 x 44 m and was configured

with a 170 m boom. A new heavy duty jib

was built especially for this project to lift

up to 1,500 tonnes at 40 m radius. Two

auxiliary cranes, a Terex Demag CC 2800,

configured with a SH/LH 78 m boom and

a 250 tonne Sumitomo SCX2500 crawler

crane, were used during the assembly.

“A number of smaller hydraulic cranes

were also used,” explained Steven Sarens,

Sarens sales manager. “We also had some

forklifts and a 100 tonne telescopic crane.”

Other challenges that had to be taken

into consideration included slinging, which

had to be pre-engineered due the size and

shape of the reactor head.

F

or its first job in Europe, Sarens’

SGC-120 super heavy lift crane

completed a heavy and long

radius lift at a nuclear power site in

Flamanville, France.

International lifting and transport

specialist Sarens, based in Belgium, used

the 3,200 tonne capacity giant crane to

install a reactor head on top of a new

building on site. The nuclear reactor head

weighed 350 tonnes and was lifted at a

radius of 140 metres.

For Sarens the main challenge was

getting the crane to the site. The crane

was shipped from China, where it had

been working on a Cosco oil platform

project (

IC

December 2012, pages 17 and

20). It landed at the port of Cherbourg in

France before being transported on trucks

by road to the Flamanville site. In total

160 containers were used to transport

the components of the crane, including

several which were then filled with around

3,000 tonnes of local ballast material, for

SITE REPORT

Super nuclear lift

Main job

With the crane assembled the team carried

out a test lift before completing the main

lift. Other lifts for the crane included the

installation of all the internal overhead

cranes for the reactor building.

“After setting up the crane we installed

the girders and the trolleys of the overhead

cranes inside the reactor – these were the

small lifts. The main lift was the reactor

head that had to be installed,” explained

Steven Sarens.

Because of the location of Flamanville,

on the coast, wind speed was a primary

concern and the team had to wait for

perfect conditions before the lift could be

carried out. With the weather on their side

the lift took one day to complete.

The crane has already been

disassembled and is due to be transported

back to the port of Cherbourg where it will

be shipped to a site in Indonesia. There the

crane will be used to install a vessel at a

petrochemical project.

■

The Sarens SGC-120 super

heavy lift crane on its first

job in Europe, lifting the

nuclear reactor head at

Flamanville in France