51

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

NOVEMBER 20

13

companion sub-paragraph

Load Test

, is pointed at the

manufacturer and contains

specific instructions for testing

and reporting.

Responsibility

The paragraph in

Load Test

describes proof testing. The

125 % proof test verifies that

no catastrophic failure can

occur when the equipment is

used as intended. Further, this

level of testing will determine if

some unexpected engineering,

materials, or manufacturing

situation has occurred which

would reduce the capacity of

the lifter to something less

than the capacity design point.

This puts the correct burden

where it belongs; on the

manufacturer. The end user

is tasked to have the equipment

‘tested’ prior to initial use and

should correctly expect, and

require, that proof testing to

be done by the manufacturer.

We believe that it is incumbent

upon the manufacturer, for

ethical, professional, and safety

assurance reasons to proof

test every below the hook

T

he issue surrounding

testing of below the

hook equipment is

the requirement for and the

industrial response to proof

testing. Technical guidance is

provided for design of below

the hook lifting devices in

ASME B30.20

, but it says very

little about testing.

The standard includes

requirements for those

functions for lifting devices

other than slings. However, in

Chapter 20 of that guidance

the word ‘shall’ is defined

to ‘indicate that the rule

is mandatory and must be

followed’ whereas ‘should’

indicates that ‘the rule is

a recommendation, the

advisability of which depends

on the facts in each situation’.

The words used in

the guidance are used

inappropriately. In the sub-

paragraph

Operational Tests

,

the equipment user is told that

‘new and reinstalled lifting

devices shall be tested by a

qualified person’; the tests

that are therein described

are essentially ‘warm up the

engine, check that the lifting

device works, check the lights

and gauges’. The user cannot

‘test’ the materials, the welds,

the design engineering, yet

they are required to test.

The next sub-paragraph,

Load Test then instructs that

‘prior to initial use, all new,

altered, modified, or repaired

lifting devices should be

tested and inspected.’ While

the former sub-paragraph on

Operational Tests

is clearly

written for and to, the user

of this equipment, this

SAFE VIEW

lifting device.

End users of below the

hook equipment provided

by some manufacturers

cannot assure that those

items have been proof tested

through their own required

inspections or from the

markings on the equipment.

Sometimes the test certificates

that are received are historic

documents that reflect batch

testing or sampling done on

like items. To avoid any such

confusion, we can track each

product from purchase order

to work order to engineering

drawings to engineer test plan

to photographic and electronic

(DVD) records of each and

every test. These DVD’s are

available to every customer.

We support the position

that the end user should

request proof testing from the

manufacturer of below the

hook lifting devices. Very few,

if any, end users could perform

the testing described by

B30.20

and yet they are told that they

‘shall.’ We are told that we

‘should’ but feel strongly that

we must. And we do.

■

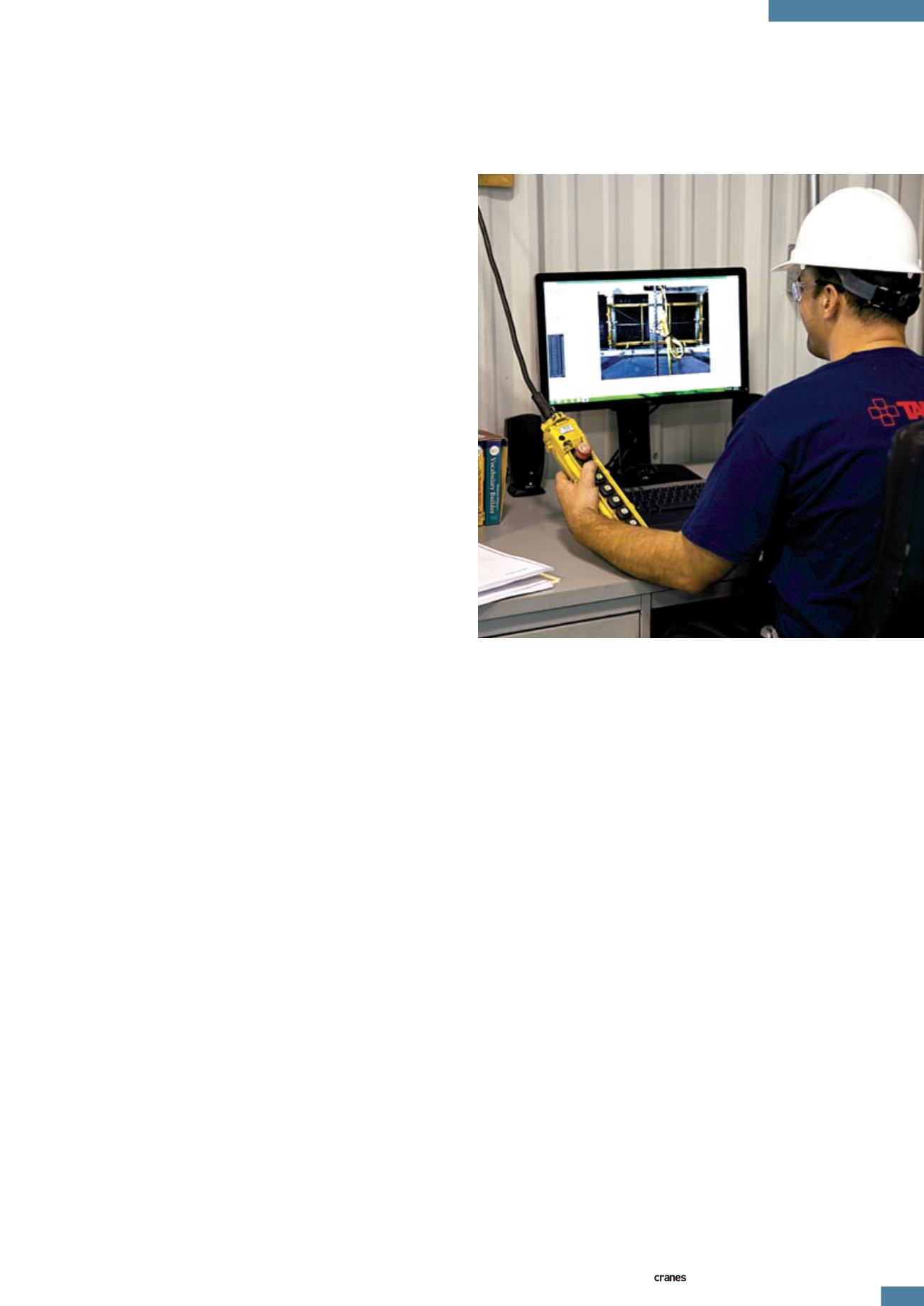

A grey area in proof testing

In addition to the

need for universal

safety standards,

testing is another

area of below the

hook equipment

that is generating

some debate

in the industry.

WILLIAM FISKE,

from Tandemloc,

discusses the

problem

“It is incumbent upon the manufacturer,

for ethical, professional, and safety

assurance reasons to proof test every

below the hook lifting device.”

William Fiske, Tandemloc