57

CONSTRUCTION EUROPE

DECEMBER 2013-JANUARY 2014

EQUIPMENT

Making an

impact

Terex Finlay has launched

a new horizontal impact

crusher – the I-100RS,

boasting variable speeds for

improved fuel efficiency and

production.

The 860mm x 860mm

crusher is designed for both

recycling and quarrying

applications. It features a

standard hopper capacity of

2.3m³, together with a 2.44m

by 1.2m single deck screen

for sizing and recirculating

oversize material back to

the crushing chamber and

hydraulic folding of all

conveyors.

This is said to provide rapid

set-up times and easy point to

point moves when operating

on multiple sites. Terex Finlay

claims the I-100RS cab be

ready for crushing in less than

15 minutes

The heavy duty crawler

tracks and optional radio

remote control unit are also

said to make on-site mobility

very easy.

The I-100RS boasts variable

speeds for improved fuel

efficiency and production

Keep on rolling

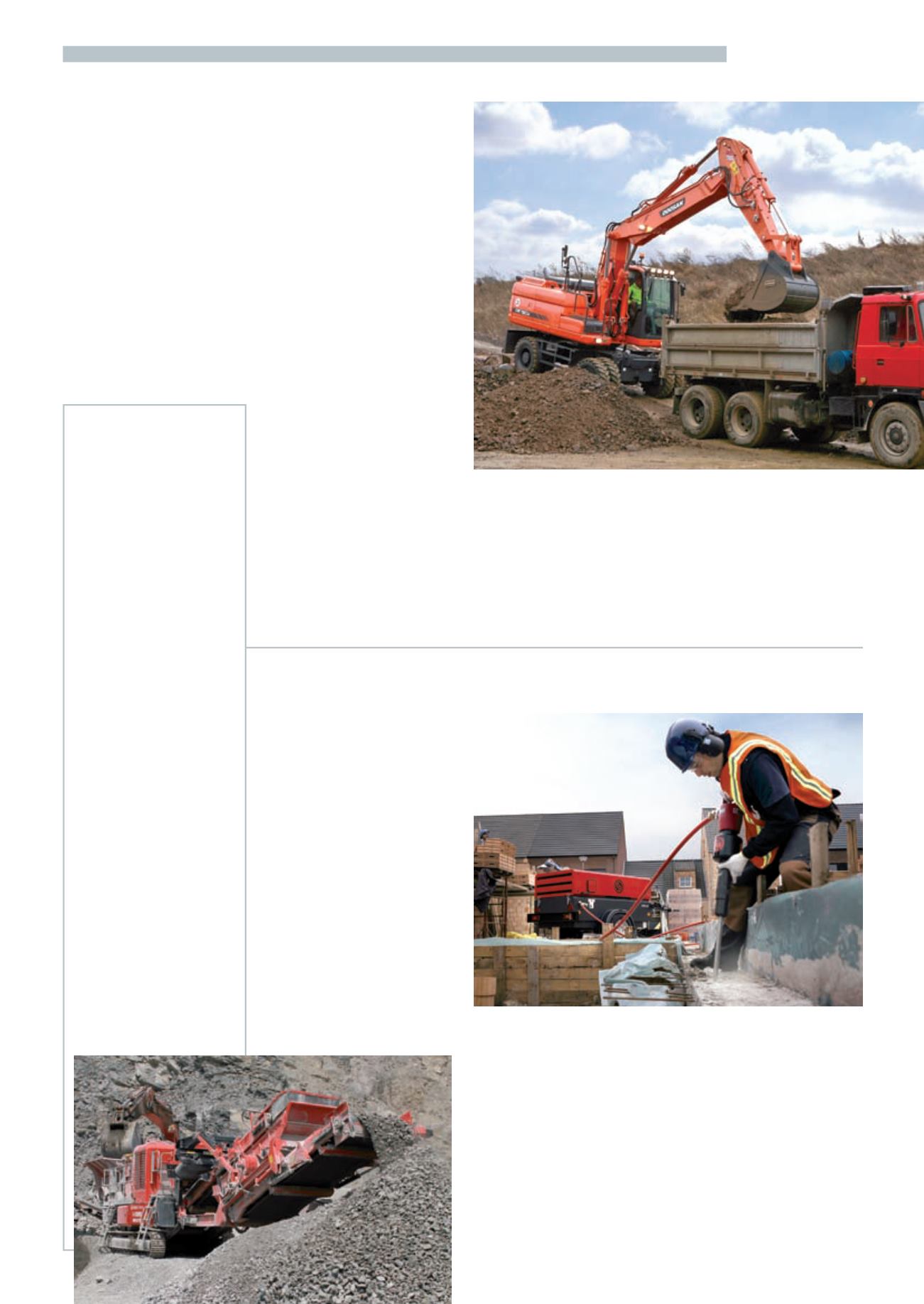

Doosan has launched a new high

performance wheeled excavator

A

new EU Stage IIIB-

compliant 19 tonne class

DX190W-3 wheeled

excavator has been launched

by Doosan Construction

Equipment.

Powered by a 129.4kW

engine, the DX190W-3 boasts

a 9% increase in engine power

compared to the Stage IIIA

model, while torque is up 4%,

according Doosan. The new

machine has also demonstrated

a 12% reduction in fuel

consumption in factory testing.

A new ECO Gauge on the

control panel monitors in

real time the rate of fuel

consumption and actual

engine-percent load to help

guide the operator to select the

best operating mode for fuel

economy.

Two new operating modes are

also available – a Power Plus

and a Lifting mode. The Lifting

mode is intended to facilitate

the handling of heavy objects

and materials on construction

sites, a feature especially useful

when working in narrow and

confined spaces, according to

the company.

The DX190W-3 boasts a 9% increase in engine power compared to the

Stage IIIA model

Doosan also said traction force

had increased 6% while swing

torque had been boosted by

16%, compared to the previous

model, while in-cab noise levels

had been reduced to 71dBA

from 74.9dBA.

The manufacturer added that

the new ROPS and OPG certified

cab also offers 6% more space

for the operator. In addition,

a new cab suspension system

is said to help cut vibration by

20%.

ce

Expanding production in Europe

Chicago Pneumatic is expanding

production of portable

compressors at its Antwerp

facility in Belgium.

The company said the move

would allow it to meet increasing

demand from Europe and

improve delivery times.

Portable compressors are

already made at Antwerp, but

the additional production line

will allow it to produce its entire

compressor range for the region

by the end of 2013. It will also

enable Chicago Pneumatic to

produce custom-built units with

additional built-in options, such

as integrated after-cooler and

water separator.

The Antwerp facility will now

manufacture all the portable

diesel compressors in the range,

from 2.5 to 5.5m³/min, as well

as the larger CPS 11, and CPS 11

to 12m³/min models, which are

already made in Antwerp.

The company also produces

portable compressors in Brazil,

the US, India and China.

Wim Thijs, product marketing

manager for portable

compressors at Chicago

Pneumatic, said, “This reflects our

on-going commitment to the

European portable compressor

market and means we are now

able to provide customers with

portable air solutions that are

made-to-order right in the heart

of Europe.”

ce

The Antwerp facility will now

manufacture all the portable

diesel compressors in the range,

from 2.5 to 5.5m³/min, as well

as the larger CPS 11 and CPS 11

to 12m³/min models, which are

already made in Antwerp