53

CONSTRUCTION EUROPE

DECEMBER 2013-JANUARY 2014

EQUIPMENT

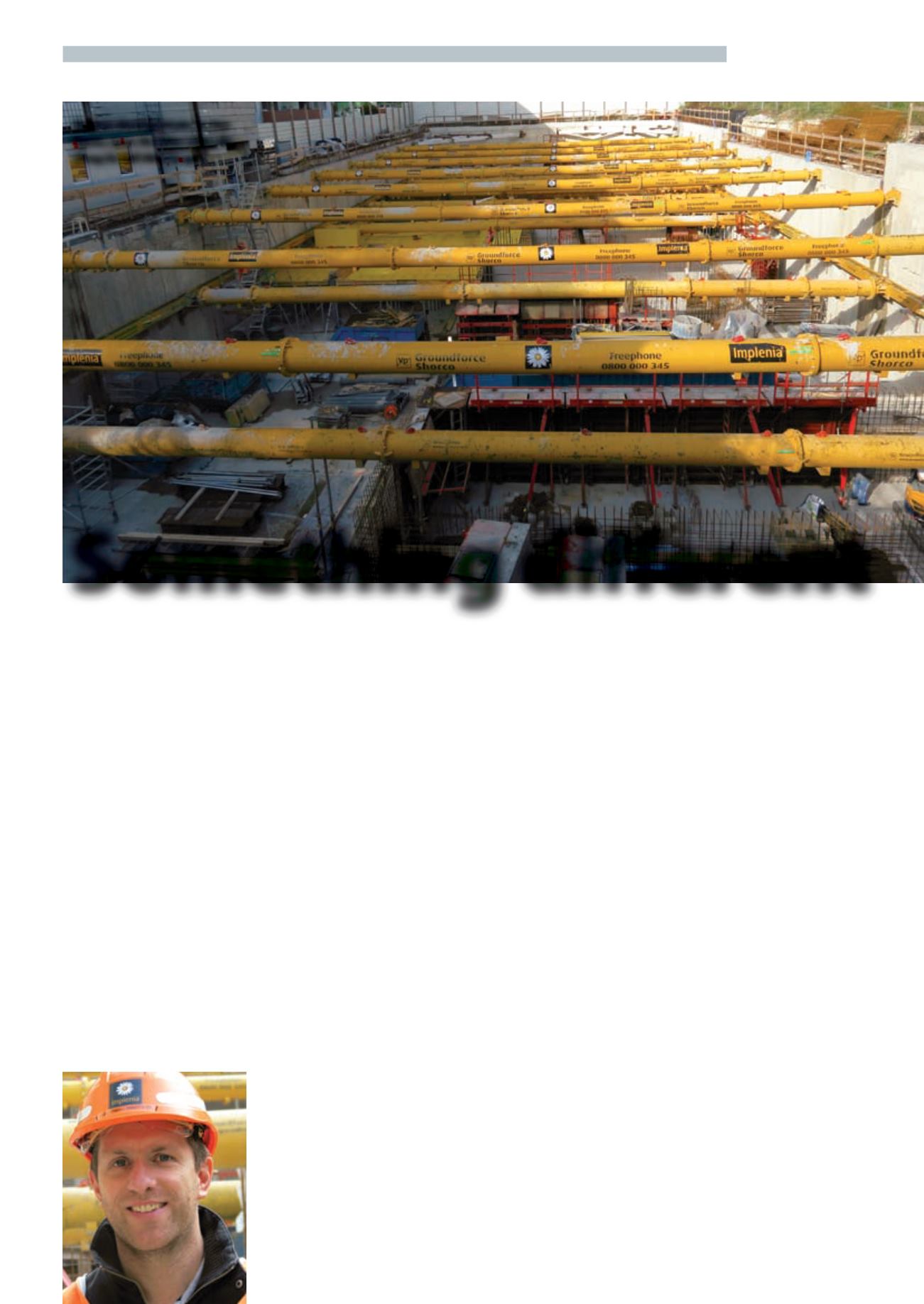

An unassuming apartment block project on the outskirts of Geneva is

helping UK rental company Groundforce introduce its hydraulic shoring

technology to the European market.

Murray Pollok

reports from Switzerland

T

he private apartment

block under construction

at Chêne-Bourg in the

suburbs of Geneva, Switzerland,

will not – by the time the first

residents have moved in by late

2014 – appear any different from

the many others surrounding it.

If unremarkable in appearance,

what does single it out as

something a bit different is the

technique used to shore up

the deep excavation during

construction – a set of 16

hydraulic shoring struts in two

layers stretching across the 26m

wide site.

These massive struts – 0.61m

in diameter on the bottom layer

and 0.51m on the top – support

the 12m deep excavation over

its full 80m length and are being

used in place of traditional

temporary steel frame shoring.

It is the first time that Swiss-

based contractor Implenia has

used the system and also its first

application in Switzerland.

Jean-Pierre Binétruy,

geotechnical engineer and

project manager at Implenia’s

foundations division, said the

company normally favoured the

tried and tested structural steel

frames, in part because they

know how to do it that way, but

also because it already owns the

steel.

At Chêne-Bourg, however,

space is at a premium, with the

site bounded on one side by a

busy road and on one of its long

edges by an existing apartment

building. It is so cramped, in fact,

that the project offices have to be

cantilevered over the excavation.

So Implenia decided to try

out hydraulic struts, a system

that it first saw at a foundations

exhibition in Piacenza, Italy,

in 2012, where it was being

displayed by Groundworks, the

trenching equipment division of

UK rental company VP.

SUPPORT DESIGN

Groundworks, which rents an

array of trenching, shoring and

piling products as well as the

more sophisticated hydraulic

struts, worked with Implenia and

civil engineering design engineer

ESM & Fiechter Ingenieries to

come up with a design for the

project.

This comprised two sets of

eight struts, the lower struts

using Groundforce’s 250 tonne

capacity MP250 units and the

upper set comprising smaller, 125

tonne capacity MP125 units.

All 16 run in the same direction,

with spacing between each pair

to allow for lowering of formwork

and other building materials.

The struts were installed two

at a time by Implenia, starting

in mid-June, while earthworks

contractor HTP used a long-reach

Komatsu PC240LC excavator –

rented from French company

ENCO – to dig out the clay.

Binétruy said the struts would

not be appropriate for simple

excavation jobs, but in this case,

the density of the alternative

steel frame structure would have

made it life difficult.

“There are two ways of seeing

the time benefits,” he said. “For

the contractor it has saved

something like a week. And for

us, it has taken just 20% of the

time required to install a steel

frame solution,” he said.

“For safety it is much better,”

he added. “The tower crane

operator doesn’t have to think

as much as with the steel frame.

And for the client, [there is a cost

saving because] we don’t need

to use vertical support beams

for a steel frame, and don’t need

reinforcement of the concrete

base slab.”

For David Williams, managing

director of VP’s Groundforce

division, the Geneva contract

is another step towards his

vision of introducing hydraulic

strut shoring technology to the

mainland European market,

substituting the temporary

steel frame solutions that are so

prevalent there, and particularly

in Germany.

ce

Something different

Jean-Pierre Binétruy, project

manager at Implenia’s

foundations division

Sixteen shoring struts, in two

layers, span the 26mwide site

along its full 80m length