provide a solid foundation for lifting – no matter

what position the boom is placed.

“These machines work in close quarters,”

Gray says. “With a typical telehandler you

always have to drive straight up to where you’re

going to unload your load. Everything has to be

straight ahead of you. A lot of times if you’re in

an industrial application or where you’ll be in

alleys, you have the ability to rotate side to side.

You can pull straight down an alley and then

reach side to side to deliver your materials or

whatever work you plan to accomplish there.”

Then there’s the obvious rotation factor, which

according to Gray, is popular with masons and

industrial contractors.

“They can set this machine up close to the

building and then provide all the loads sitting

out from it. So, since it can slew around and

reach out, it can pick up loads and take them

up. Almost like a crane during building and how

it sits and places steal. This sits and places

materials and it doesn’t have to keep driving

back and forth.”

Education

With a rotating telehandler able to reach nearly

100 feet and lift loads similar to those a truck

crane might, it could be shocking as to why

the units aren’t more popular here. Then again,

changing a paradigm is never easy.

“At first, there is always skepticism,” Gray

says about customers-to-be. “In the U.S., jobs

are done the same way. You have to make

people see things differently and that’s not

always easy. You have to educate the customer;

show them the cost savings and what they can

accomplish with a rotating telehandler.”

While all those factors might point to good

sales, rotating telehandlers typically price-

out 30 to 50 percent more than a traditional

telehandler. It’s sticker shock. But many people

will vouch for how little time it can take to get a

ROI – some say 18 months is it.

“This is a lot less expensive than a crane,”

Gray says. “There

are less costs

associated with

operators –

compared to a ‘true’

crane operator –

plus the machine

is very versatile.

It has a number

of attachments

such as winches,

personnel baskets,

and more. That’s

where a lot of cost

savings come into

play.”

New units

In late 2013,

Manitou Americas debuted a number of updates

to its rotating MRT line.

The updated MRT Series includes the MRT

1840 Easy 360-degree, MRT 2150 Privilege Plus

and MRT 2540 Privilege Plus. The MRT Series is

designed to meet the needs of rental companies

and contractors in construction applications with

space constraints.

The MRT 1840 Easy 360 is powered by a 101

hp (74.5 kW) Perkins Interim Tier IV-certified

turbocharged engine and the MRT 2150

Privilege Plus and MRT 2540 Privilege Plus are

powered by 150 hp (110 kW) Mercedes-Benz

EPA Tier III turbocharged engines. The engine

automatically adapts itself to the needs of the

transmission system. This provides significant

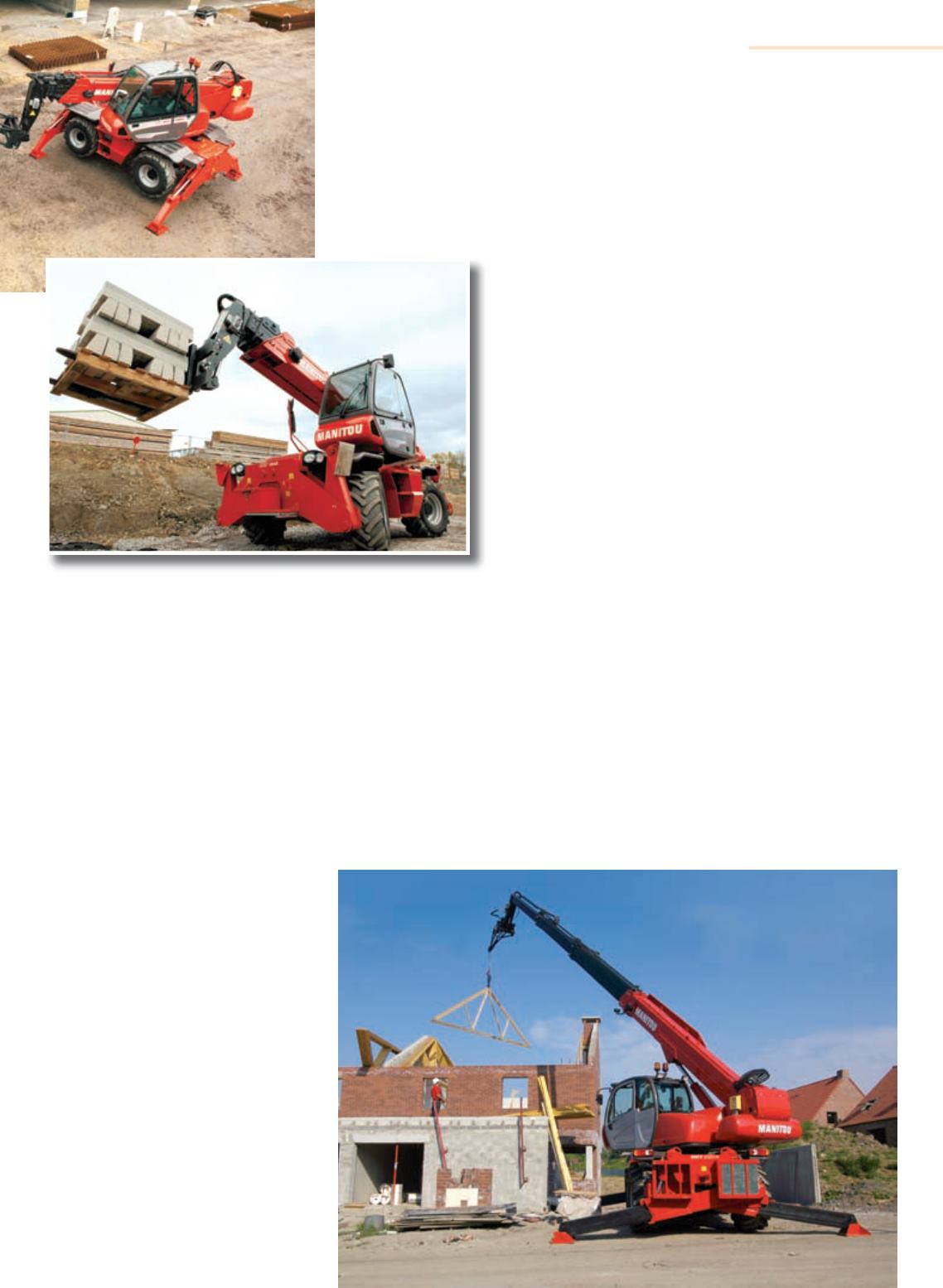

Manitou made a number of updates and

changes to its rotating telehandler line,

including the MRT 1840 pictured here.

fuel consumption reductions by matching engine

output to the machine’s operation, Manitou said.

The two-speed hydrostatic transmission in all

models provides power and control for precise

placement of the machine. The MRT Series

models feature 4-wheel drive and oscillating

rear axles.

With a lift height of 80 feet and 8.5 inches

(24.6 m) on the MRT 2540 Privilege Plus,

operators can move materials to high buildings

and structures, elevate work platforms and

carry out service and maintenance work for the

mining, oil and gas industries. Lift capacities

are 11,000 pounds (5,000 kg) on the MRT 2150

Privilege Plus and 8,800 pounds (4,400 kg) on

the MRT 1840 Easy 360 and MRT 2540 Privilege

Plus models.

The new E-RECO – Automatic Attachment

Recognition – system comes standard on the

MRT Series. The system automatically senses

the attachment when correctly installed and

assigns the correct load chart and safe operation

zones. This allows the operator to know the lift

capacities of the attachments he/she is using

around the jobsite.

Front and rear stabilizers come standard on

the MRT Series. A telescopic scissor design on

the Privilege Plus models enables the legs to be

partially deployed when obstacles are present

or space is limited. When the stabilizers and

pads are retracted, they are integrated into the

machine’s body. There is no loss of ground

clearance or addition to machine width, Manitou

said. An adaptable calculator adjusts the load

chart and lifting zones based on the position of

the stabilizers.

For increased safety, an oscillating axle

lock-out system engages when the machine is

standing on its wheels and the upper structure

is rotated by more than 15 degrees. This allows

work to be completed with a larger area of

stability for the machine.

A spacious, ergonomic cab is equipped with

two electro-hydraulic joysticks that control

TELEHANDLERS

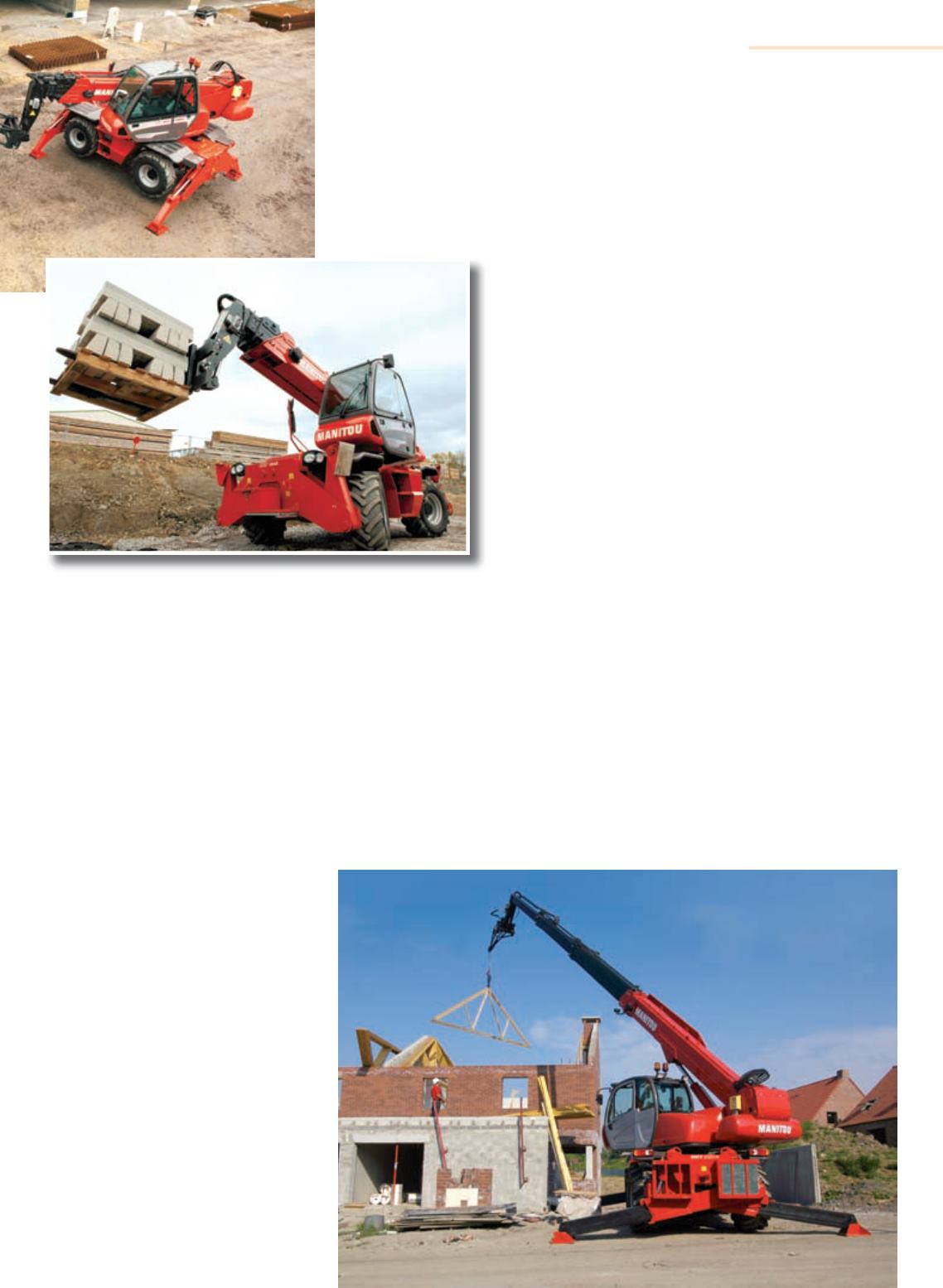

A Manitou MRT 2150 with a

jib attachment.

17

JANUARY-FEBRUARY 2014

ACCESS, LIFT & HANDLERS