TELEHANDLERS

T

hey’re big, they’re powerful and they turn

on a dime. No, we are not talking about

Olympic figure skaters. We’re talking about

rotating telehandlers.

Long the workhorse in cramped Eurpean

quarters, rotating telehandlers have been around

for more than 20 years, but they’re still in their

infancy in the United States and other parts of

North America.

The three main players in the U.S. and Canada

are Dieci, Manitou and Merlo, with Manitou

being the first manufacturer to bring the

technology from Europe to the States in the early

2000s. With 14 years under their belts, rotating

telehandlers have gained some attention.

“They’re construction machines,” says

Andy Gray, territory sales manager for Applied

Machinery Sales (AMS). AMS is the U.S.

distributor for Italian-built Merlo telescopic

handlers. “Applications are becoming more

diverse as people realize the versatility of these

machines, but that said, the two largest users of

rotating telehandlers are probably masons and

industrial contractors.”

Merlo manufactures 90 percent

of its components with more than

100 engineers, according to the

company. The end product is a

versatile, advantageous piece of

equipment, Gray says.

“With a rotating telehandler,

you have a couple of distinct

advantages over a normal

telehandler,” Gray says. “It has

the same capacities and runs

similarly, but on almost all rotating

telehandlers, you have a longer

stick and you can work in close

quarters.”

Rotating telehandlers are

designed differently from their

straight-facing counterparts. With

two distinctly diverse sections

– the upper section boom and

operator’s cab and lower section’s

engine, chassis, outriggers, fuel

and other mechanisms – a rotating

telehandler is joined ‘at the waist’

on a turret that allows the machine

to rotate an unlimited 360 degrees.

Rotating teles typically have

outriggers in front and back to

Rotating telehandlers are making headway in North America.

Lindsey Anderson

reports on the latest from Dieci, Manitou and

Merlo and how these units can work for the bottom line.

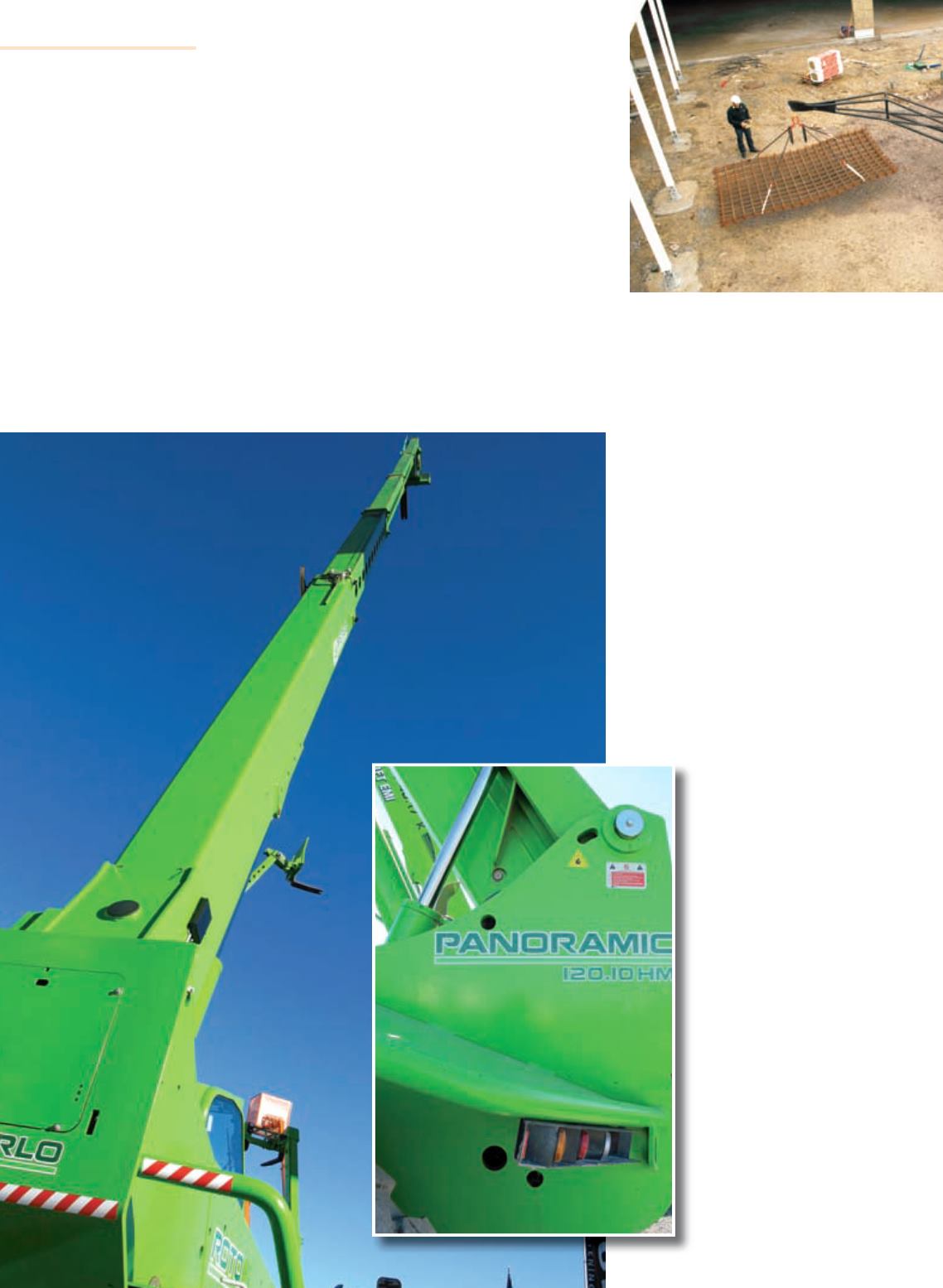

Merlo entered the U.S.

and Canadian markets

through its two

distributors, Canada-

based Manulift and

U.S.-based Applied

Machinery Sales.

One of Manulift’s many

Merlo telehandlers.

16

ACCESS, LIFT & HANDLERS

JANUARY-FEBRUARY 2014

Money-

spinning

An operator places materials

remotely with a Manitou MRT 1840.