31

CONSTRUCTION HOISTS

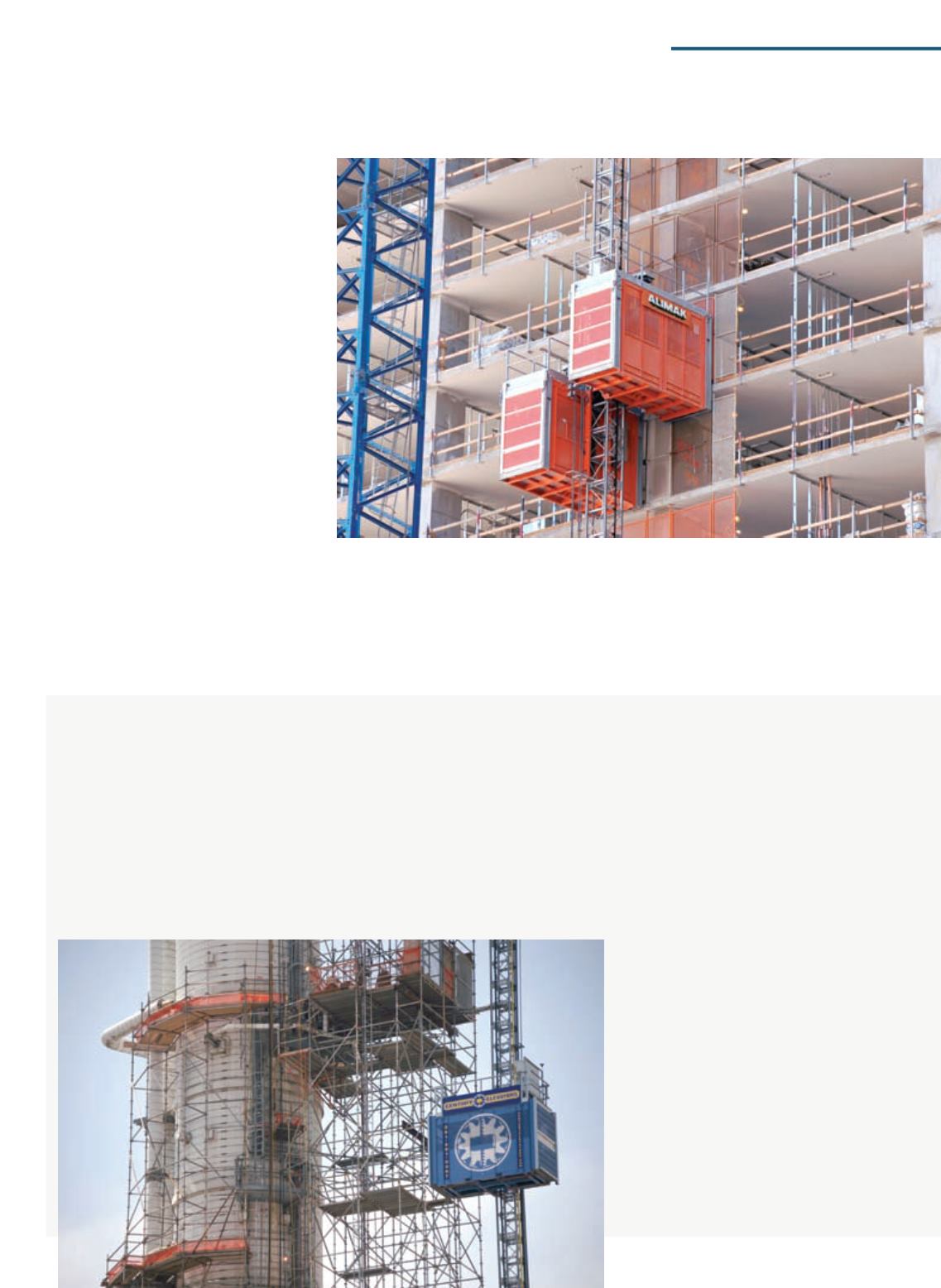

Manmade in New York City

I

n New York City, 50 UN is a 44-story

condominium project located on the west

side of 1st Avenue in Manhattan, occupying

the full block between 46th and 47th Streets.

Prices start at $2.8 million for a one-bedroom

unit and duplex penthouses, one of nine,

reportedly are asking for $55 million.

Universal Builders Supply was awarded the

contract for the hoisting and protection work,

which included a four-car hoisting complex,

a two-car subgrade hoist as well as sidewalk

bridge, roof protection and other protection work

associated with the project.

The above grade hoisting complex consisted

of a UBS high-capacity platform solution

positioned on the south face of the building

with two dual Alimak Scando 650 Hoists. The

common platform was extended at the base with

a large loading dock complex complete with

overhead protection, ramps and stairs, and had

landings at all floors from the 2nd to the 42nd

floor. The overall lifting height of the hoists was

approximately 500 feet. The common platform

was erected in conjunction with the building

construction to maintain pace with the top-most

floor under construction to provide protection at

these floors.

The west dual hoist was custom designed and

built to carry 7,000 pounds of capacity, could

run 328 feet per minute as a dual personnel/

GEDA cracks Port Arthur job

The east dual hoist was a standard-length,

7,000-pound capacity, 328 feet per minute,

dual personnel/material hoist with inside clear

cab dimensions of 12 feet, 9 inches long by 4

feet, 11 inches wide by 7 feet by 6 inches high.

All cars were equipped with overload sensing

devices and manual controls with stop-next-

material hoist and had inside cab dimensions

of 18 feet long by 4 feet, 11 inches wide by 9

feet, 2 inches tall. The front and rear gates were

able to open to nearly the full interior height of

the cab, with corresponding custom designed

and fabricated landing gates on the common

platform.

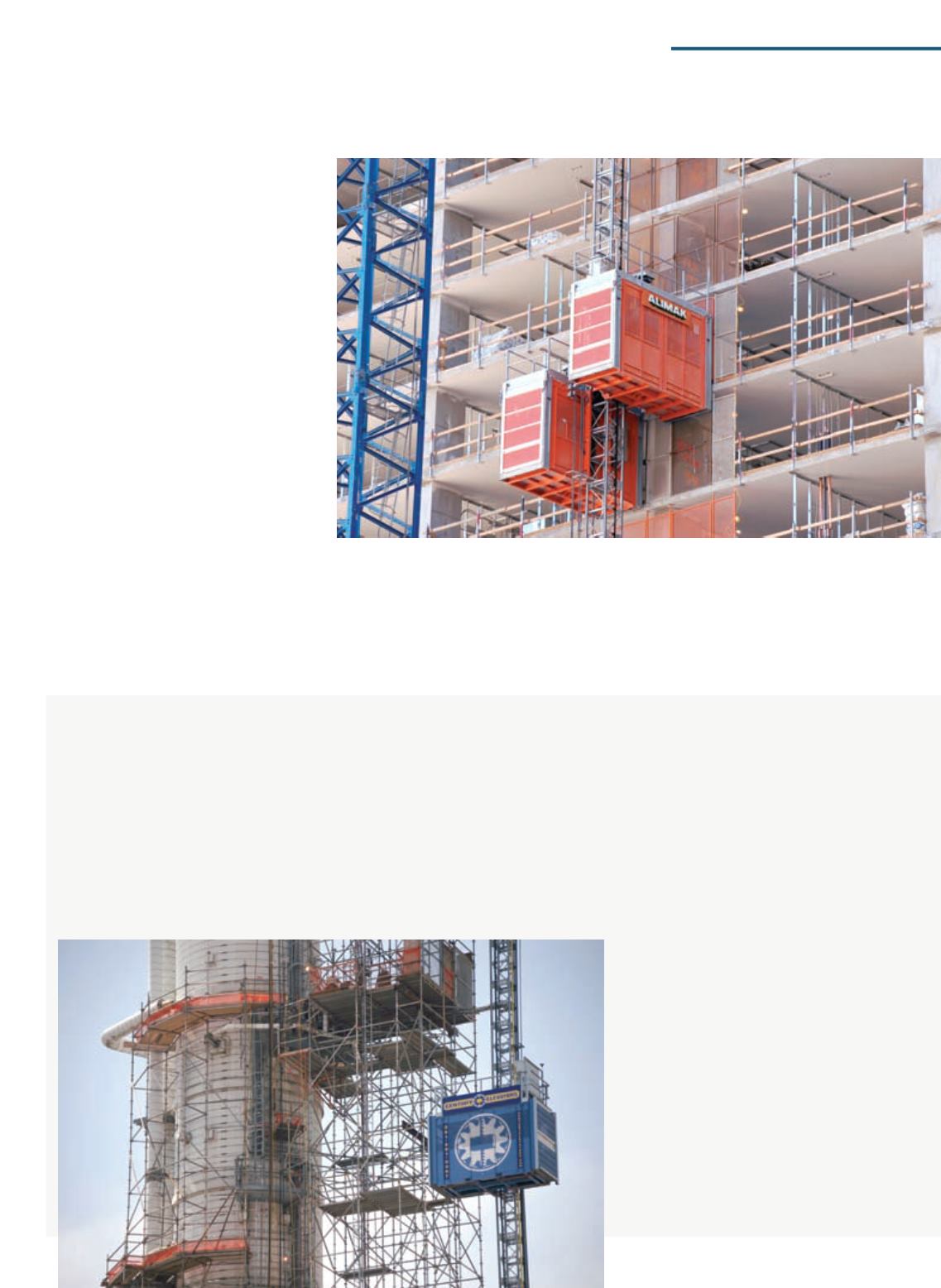

H

ouston-based Century Elevators was

contracted by BASF to provide a

construction hoist – a GEDA PH 3240

650 Twin – recently for a 301-foot steam

cracker tower at the Port Arthur oil refinery in

Texas.

The benefits of this construction hoist were

clear to see, Eric Schmidt of Betco Scaffold

said. The hoist had a lifting speed of 213 feet/

min with a maximum lifting height of 1,312 feet.

A total of up to 30 people or an overall material

weight of 7,054 pounds could be transported on

the 5 foot by 13.1 foot platform.

A PH double car was used on the BASF steam

cracker. That meant that two cars – one on the

left and one on the right side of the mast – could

travel upward and downward independently of

each other.

“The scaffolding and lift must be attuned to

each other with great precision and therefore

the scaffolding was specifically strengthened to

withstand the anchoring forces of the lift with its

two cars,” Schmidt said.

Although most of the maintenance work was

to be completed before the start of the hurricane

season, the scaffolding and lift mast had to be

designed to resist hurricane-style wind gusts.

Since the Gulf of Mexico is one of the world’s

most hurricane-affected regions, the PH 3240

650 Twin was also equipped with a special wind

gauge.

Safety was paramount, Schmidt said. Before

each shift the car, mast and anchorage were

inspected and approved for use. Racks, pinions,

gates, doors, limit switches, brakes and other

electrical and mechanical components were

also checked to ensure the safe and precise

operation of the lift.

Two machine operators and two technicians

were on-site 24 hours a day for the duration of

the work.

■

NOVEMBER-DECEMBER 2013

ALH

MAST AND HOIST SUPPLEMENT