41

SEPTEMBER-OCTOBER 2014

access

INTERNATIONAL

INBRIEF

■

International scaffold distributor

AA International Trading (AAIT) has

opened a facility inMiami to serve

NorthAmerican customers. The

Florida-based company has been

distributing scaffolding to South

America since 2010, but due to

increased activity inNorthAmerican

construction and the oil & energy

industries, the company decided

to begin distributing its system

scaffold products to scaffold rental

organisations acrossNorthAmerica.

■

TheConstruction Industry

TrainingBoard (CITB), working

with theUK’sNational Access

&ScaffoldingConfederation

(NASC) andConstruction Industry

Scaffolders RecordScheme (CISRS),

has relaunched its level 2 diploma

for scaffolding apprentices, and

began to offer the newDiploma

inScaffolding from 1September,

2014. Themain focus has been to

bring the diploma in linewith the

launch of theNASC’s newBest

PracticeGuidelines for Tube and

FittingScaffolding (TG20:13).

Youngman to be

acquired byWerner

SCAFFOLDING INTERNATIONAL

W

ernerAccess Products

UKHolding is set to

acquire 100%of the

shareholdingofYoungmanGroup.

The acquisitionwill combine

Youngman’s tower and low level

access productswithUS-based

WernerCo’sUK ladder business,

Abru, and is subject to clearance

from theUKCompetition and

MarketsAuthority. The deal is

expected to complete at the endof

October, saidWernerCo.

“This acquisition continues

Werner’s expansion in the

world-wide ladder and access

productsmarket,”saidWilliam

Allen,Werner chairman. “The

Youngman andBoSSbrands

arewell recognised tower and

trade access product brands in

Doka buys in Australia

NASCSCAFFOLD

CHECKLIST

F

alsework and formwork

manufacturerDoka has

expanded inAustraliawith

a deal to acquire local construction

companyGrocon.

Doka acquired the formwork

patent forLubeca Jumpform

automatic climbing formwork

alongwith employees and a

project portfolio fromGrocon.

Doka said it planned touse the

deal to establish a new subsidiary

calledLubecaPtyLtd,withoffices

TheNASC haswelcomed the

publication of the recently amended

UK-basedHSE Scaffold Checklist.

The document is intended to

clarifywhen scaffold design

is required, and the level of

training and competencewhich

those erecting, inspecting and

supervising the erection, alteration

and dismantling of scaffolding are

expected to have.

Information and advice contained

within the revised document

relates to all types of scaffolding

structures. All key areas have

been covered, including planning,

client/user responsibilities,

design information requirements,

competence and supervision of

operatives, inspection of scaffold

structures, and the requirement for

adequate fall preventionmeasures.

NASC president, KevinWard said,

“The HSE should be applauded for

producing an excellent updated

version of the HSE Scaffold

Checklist. I think thiswill be a very

useful and informative document

for scaffolding contractors, users

of scaffolding and persons affected

by scaffolding operations. It is a job

reallywell done.”

inMelbourne inVictoria state.

ADoka spokesman said

LubecaPtyLtdwouldbe a

rental-only business offering

Lubeca Jumpform to construction

companies for concretingwork in

emergingmarkets.

Austria-headquarteredDoka

said theGrocon acquisition and

establishment of theAustralian

subsidiarywould also allow it

todevelop a stronger presence

not only inAustralia,but also in

theMiddleEast andEastAsia,

includingSingapore,Malaysia and

India.

JohannStrunz,DokaCEO in

charge of overseasmarkets, said

bothDoka andLubeca benefitted

from this integration.“Our

diversity offers customers a broad

range of formwork systems and

ideal solutions for any customer

requirement and structure.

This acquisition is a valuable

complement,”he added.

AI

theUnitedKingdom andfitwell

withWerner’s existingUK ladder

business.

MrAllen added,“We’re

confident that the deal will benefit

the industry by allowingus to

offer a single integratedportfolio

that combines our complementary

strengths –Youngman’s focus on

towers andother trade products

andWerner’s focus on ladders and

otherDIY access products.”

AI

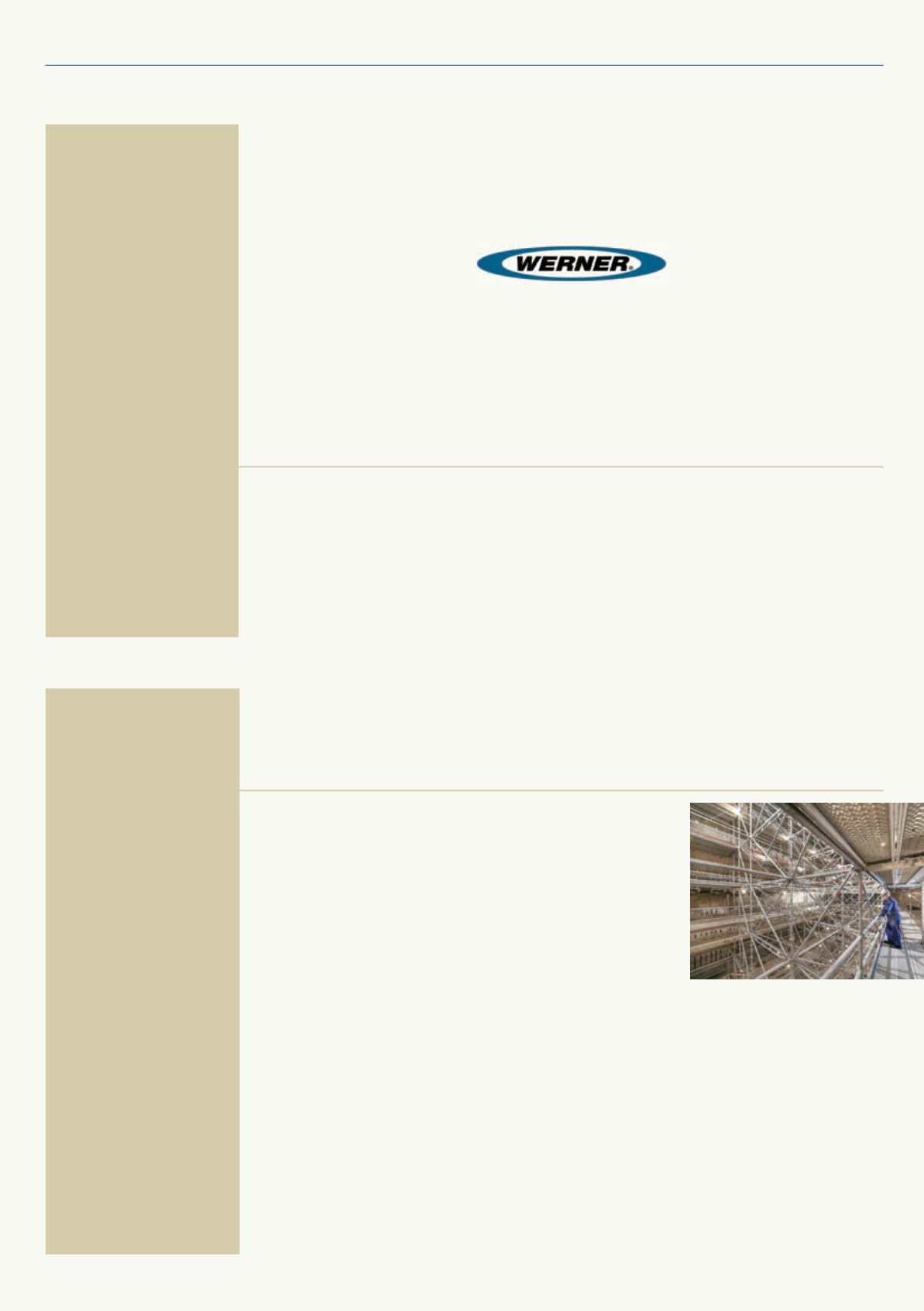

Powering up

X

ervonPalmers has used

system scaffolding to

provide access for the bi-

annual overhaul of the interior of

a huge boiler atAberthawPower

Station, inSouthWales,UK.

Working closelywith client

DoosanBabcock and its customer

RWE,up to 47XervonPalmers

operatives have constructed a 25

x 13m, 19-lift Layher System

Scaffoldwithin the enormous

coal-fired boiler at the power

station, locatednearCardiff on

theNorth bank of theBristol

Channel.

The decision to useLayher

SystemScaffolding in preference

to traditional tube&fitting

scaffoldingwasmade to improve

the performance and efficiency of

the scaffolding to suit the large,

but confined spacewithin the

power station boiler and the time

constraints of the contract.

A key factor of the Palmers

job atAberthawwas to help

reduce the amount of time the

boiler was offline.The boiler

helps the power station generate

1555MW of electricity to the

national grid, enough for three

millionhomes.

TheAberthaw contractmeant

operativeswereworking inhot,

dusty andnoisy conditions and

had limited storage facilities for

the significant amount ofmanual

handling that was required

to get theLayher equipment

initially through two small (48 x

18 inch) holes to erect the first

three scaffold levels. Aswork

progressedmaterialswere passed

through larger doorway-sized

holes above levels three to 19.

“As a company,we are starting

to see a rise indemand for system

scaffolding jobs now – even in

traditional tube andfitting areas,

likeEngland.System is the

scaffold of choice inEurope and

very popular inScotland too, so

it’s interesting to see it taking a

more prevalent role inEngland

now,”commented IanMcFarlane,

director at XervonPalmers.

Palmers’parent company

XervonGmbH based in

Germany is one of the biggest

scaffold companies inEurope.

AI