34

MAST CLIMBERS

Global intentions

For Italian manufacturer Safi, niche operations and

emerging markets are its livelihood.

S

afi is using its relatively small size to

concentrate on niche markets, which

are attracting more business for mast

climbers.

“We can customise our machines for any

request. Our last machine was a special

machine for the shipyard industry in Italy,

it can lift materials and persons up to 13

tonnes,” says Nael Souqi, regional sales

manager at Safi.

Safi has turned its attention shipbuilding.

Three months ago it started work in Venice to

install cabins into a 60 m high cruise ship.The

cabins are pre-build elsewhere and transported

to the dockside, where Safi’s machine

transports them straight off the trailer and up

to the appropriated position in the ship’s hull.

Safi is also working on a tower crane hoist

in readiness for EN regulations that come in

to force in 2015.They state that tower crane

over 40 m high must have an operator hoist.

It will have a hoisting speed of 15 m/min, one

electric motor, a mechanical safety break, and

can be controlled from the ground or hoist.

Capacity will be about 300 to 400 kg.

Asia is a particularly interesting destination.

The company has designed a platform for

tunnels. “In Asia, and many countries in

Europe, you have very high prices for land,

so now governments are looking to more

Maber recently installed two MB C 2000/150-SR transport platforms with VFD for use in the construction of

a cruise ship for Italian shipbuilder in Venice.

The MB C 2000/150-SR transport platforms are being used for transporting people and small loads. The

platforms have a capacity of 1500 kg each and a dimension of 1.5 m x 3.2 m, and have been fitted with a

VFD (variable frequency device) for smooth start and stop, reducing power consumption. They offer a hoist

speed of up to 32 m/min for loads and 12 m/min for persons.

Maber also developed a mechanical system to automatically adjust the entry level on the dock, either up

and down or left and right, to accommodate changes in tide, wind and the weight of the vessel.

The ship, which measures 38 m wide and 50 m high with a total length of 300 m, can move up to 1.5 m

up or down and 1.2 m left or right due to tide and wind fluctuations.

SHIPBUILDING IN VENICE

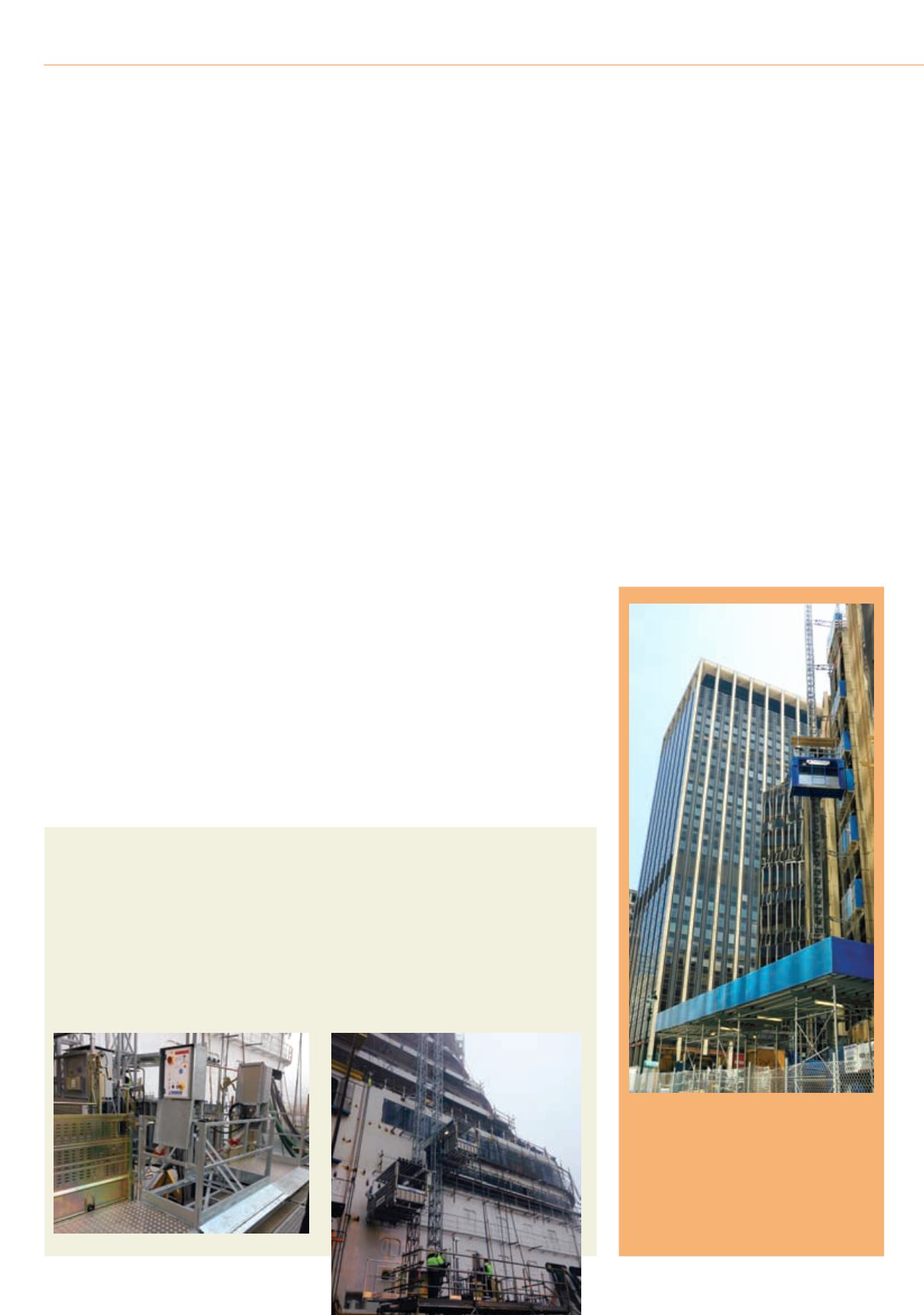

Stros, a Czech Republic-based

manufacturer, has entered the North

American market by storm over the

last few years. According to Ondrej

Susa, Stros sales manager, business is

outstandingly good for the company right

now, especially in New York (pictured

here) and Toronto.0

access

INTERNATIONAL

JANUARY-FEBRUARY 201

4

underground projects for power cables, waste

water, metros, etc,” says Mr Souqi.

Specifications for the machine are still

under wraps, but the product will move

downwards as the ground is excavated, by

placing new mast sections underneath each

time it arrives at the bottom of the section it

is using.

“There are a lot of competitors, so we have

to find out clients in these types of projects

where no one can compete. We are small

and flexible, which means you can give us a

problem and we can provide a solution.”

The Middle East is very important to the

company, with 35-40% of its exports going to

the region. However, there are still challenges.

“The Middle East is a difficult market; you

have explain these ideas to the contractors to

change their mentality.”

Looking further east, he adds, “I think

the South East Asia is the most important

market nowadays; Singapore, Malaysia, which

is booming, and Indonesia - governments are

providing more for infrastructure.”

Mr Nael continues, “Oil and gas is also very

important, because we make explosion proof

machinery – for us there is a lot of business

around this type of elevators.”

In the home market of Europe rental is

becoming increasing important. “A rental fleet

gives a second option to contractors to save

some money.” Of business in Europe rental is

around 40%, while sales stands at 25% - sales

used to be around 35%.

Mr Souqi provides an example. Often

machines are used for one job, and then must

be stored at great expense and depreciate in

value as they sit around waiting to be used

again.

A machine that costs €100000 new will be

subject to those extra costs. But if the company

chooses to rent, it will get full service for the

entirety of the job and then the machine will

be taken of its hands – the total cost may be

around €60000; in effect a saving of €40000.

“It’s very simple but very important to avoid

having machines in warehouses.

AI