TRANSPORT

SITEREPORT

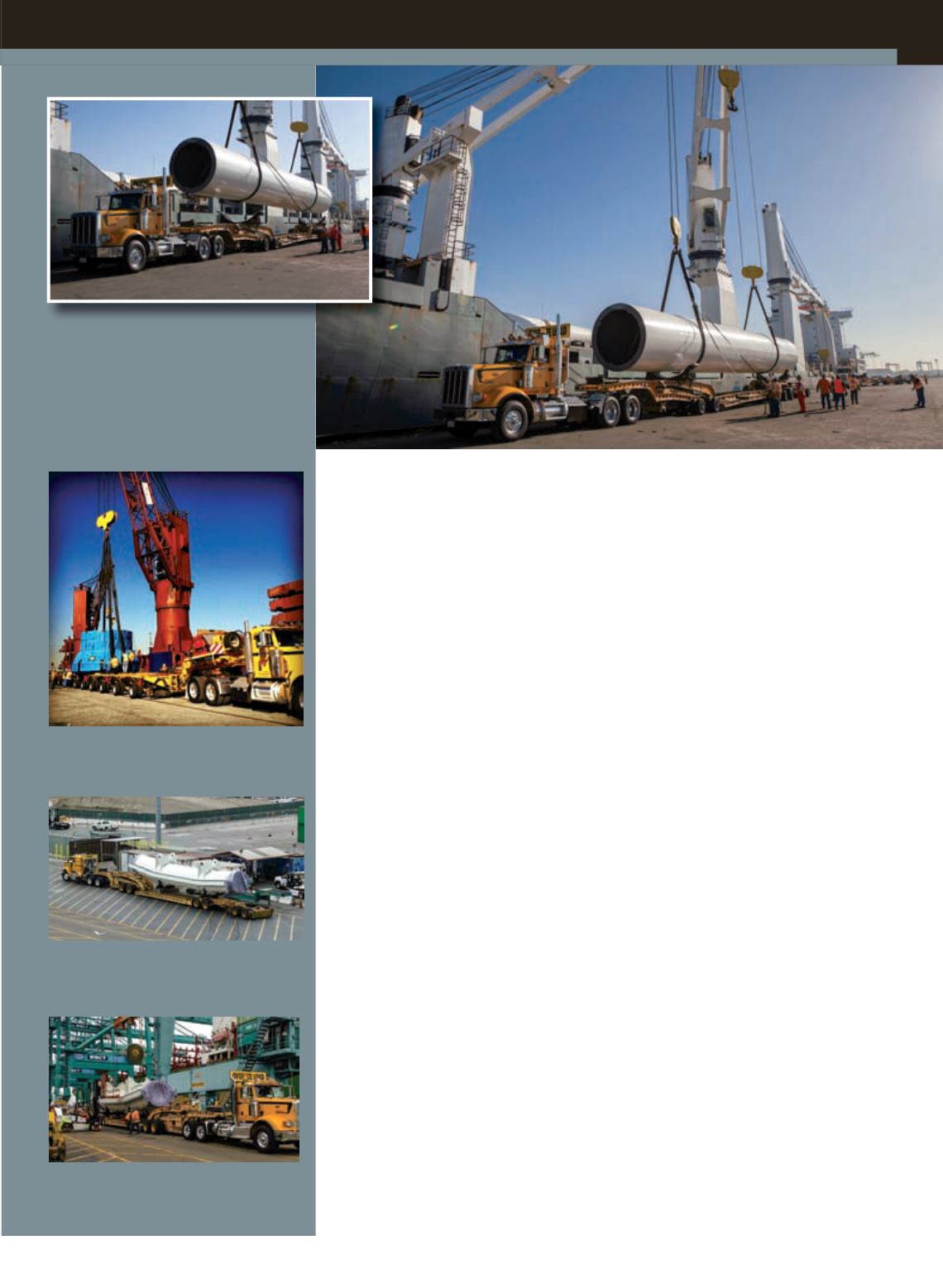

Trucking the components

of theHighRoller required

meticulous scheduling and

heavy haul acumen.

C

omponents for theHighRoller

ObservationWheel inLas

Vegaswerehuge, heavy and

awkwardly shaped. Fabricated in theFar

East, the rim and support systemswere

shipped to thePort of LongBeach in the

order ofwhen theywouldbe erectedon

the jobsite.HeavyTransport, based in

LongBeach, CA,was selectedbygeneral

contractorAmericanBridge tohaul the

pieces toLasVegas in a time frameof just

under a year.

Since thePort of LongBeach is

practically inHeavyTransport’s back

yard, the company is very familiarwith

working at theport, according toKevin

Reese, operationsmanager. He saidhis

team approached the 68-load jobmuch

like theydowhenhaulingwind tower

components.

“Weusedourwind tower saddles,

whichworked reallywell for cradling and

tie-downof thepieces,”Reese said. “For

the rim sections,wewould loadout one

day and thendeliver thenext. In all, the

project involvedhauling some 6.3million

pounds of steel.”

Relatively simple

The rim sectionswere shipped into the

port six at a time. Theywere liftedoff the

ship andontoHeavyTransport’s trailer by

aport crane.

Hauling the

HighRoller

57

Whilehauling the 95,000-pound,

55-foot long rim sectionswas relatively

simple, hauling the center hub and leg

support sectionswas another story.

“Eachhubwas 20 feetwide andweighed

in excess of 300,000pounds,” saidReese.

“Themiddlehub sectionwas 80 feet long,

15 feetwide, loaded at 19 feet tall and

weighed250,000pounds.

For thesehauls,HeavyTransport used

their 10-axle ScheuerleWideCombi dual

lane trailer configuration. The route from

LongBeach toLasVegas had tobe altered

for the three super loads due toheight

andweight restrictions onCalifornia and

Nevada interstates, Reese said.

“Those loads requiredpolice escorts,

pilot cars andbucket trucks and took

about threedays to complete eachof the

threemoves,” saidReese.

For themost part, the componentswere

delivered to a staging area for immediate

building.

“Itwas a reallygoodhaulingproject for

our company,” saidReese. “Therewere

noproblems, and everythingwaswell

planned.”

Aswas reported in theMarch2014 issue

of

ACT

, theobservationmoduleswere

fabricated inColorado andhauled toLas

Vegas byEmpireTrucking. TheHigh

Roller is planned toopen inmid-April

2014.

■

Heavy Transport

hauled the High

Roller sections

much like they

haul wind tower

components.

Eachhubwas20 feetwide andweighed in

excess of 300,000pounds. Themiddlehub

section loadedout at 19 feet tall.

Theproject tohaul the rim andhub

componentswas a68-load job in a just

under one-year time frame.

Pick-up anddeliverywas performed in the

order the componentswereneeded for

constructionof thegiant observationwheel.

APRIL 2014

ACT