25

OCTOBER 2013

ACT

RIGGING REVIEW

Tim Hillegonds

reports that the

nuances of wire rope are

complicated and varied.

W

hen most folks think of

Texas, they think big – big

hats, big guns, big hair. But

if you travel about as far south as a car

will take you, just one long bridge away

from the excitement of South Padre Island,

you’ll eventually reach Port Isabel, a small

town situated just off the western edge of

the Gulf of Mexico.

With a population of about 5,000, the

town is small, but it’s also somewhat

lively, and it’s not uncommon to see crane

booms stretching into the sky above the

cerulean waters of the Gulf. The economy

isn’t necessarily booming by any means

– most of it is built on tourism that is

spotty at best – but construction jobs are

still underway and cranes can be found

picking and setting everything from rebar

to HVAC units to generators.

But on one particular day in early May

of 2009, it wasn’t a boom reaching toward

the big Texas sky that was causing people

to stop and stare, it was one that was lying

in a heap just beside the water, lattice

sections bent and lacings twisted into mess

of mangled steel and frayed wire rope.

“I got the call to investigate the cause of

loss on a Manitowoc 888 that was being

used to drive underwater pilings at a dock

in Port Isabel,” says JR Bristow, of Bristow

Truck and Equipment Specialists, an

organization based in Ridgewood, NJ that

provides failure analysis and appraisals,

among other things, for heavy equipment.

“The operator was hoisting the boom

when it just sort of gave out and crashed

to the ground. No one was hurt, but the

boom was in bad shape. The initial reserve

was set at $500,000.”

Though a half million dollars wasn’t a

total loss – the crane was valued at $1.5

million – it was a pretty hefty price to pay

for something that, as it turned out, could

have been avoided. On lattice-type cranes,

booms are raised and lowered using boom

hoist wire rope, and when that wire rope

shows surface wear or corrosion, or worse,

has broken wires within the rope strand, it

can fail. It’s usually just a matter of time.

Out of service condition

The subsequent investigation that followed

revealed that the wire rope used to hoist

the boom of the Model 888 had been in

an out-of-service condition for quite some

time, due to lack of proper lubrication.

“An examination of the failed boom

hoist wire rope revealed that the wire rope

had gone without the proper lubrication,

which was the responsibility of the insured

per the attached lease agreement,” Bristow

remembers. “I also noted significant

broken wires within the rope strands at an

average of six to 12 per strand lay. Clearly,

if the insured had performed a daily

inspection of the boom hoist wire rope

as required, that incident would not have

happened.”

The broken strand condition that

Bristow observed was caused by load

cycles that occurred during boom up

and boom down functions that were

part of the daily operation of the crane.

Simultaneous compression and expansion

of the wire rope usually occurs as it travels

over the hoist sheaves, and that causes the

gradual deterioration of the strand wires.

Like many other segments of the crane

and rigging industry, the nuances of

wire rope are complicated and varied.

Considerable time, money and resources

have been invested in new technology,

new inspection suggestions and new

manufacturers. And rightly so. As was the

case in Bristow’s example earlier, there’s

quite a bit at stake in terms of both human

capital and equipment cost.

Python High Performance wire rope, a

wire rope manufacturer that has produced

a number of resources to assist people in

understanding and ultimately purchasing

wire rope, clarifies the structure of wire

rope on its website

Python’s site explains that a typical wire

rope can contain hundreds of individual

wires. These wires are fabricated and

formed to operate at close bearing

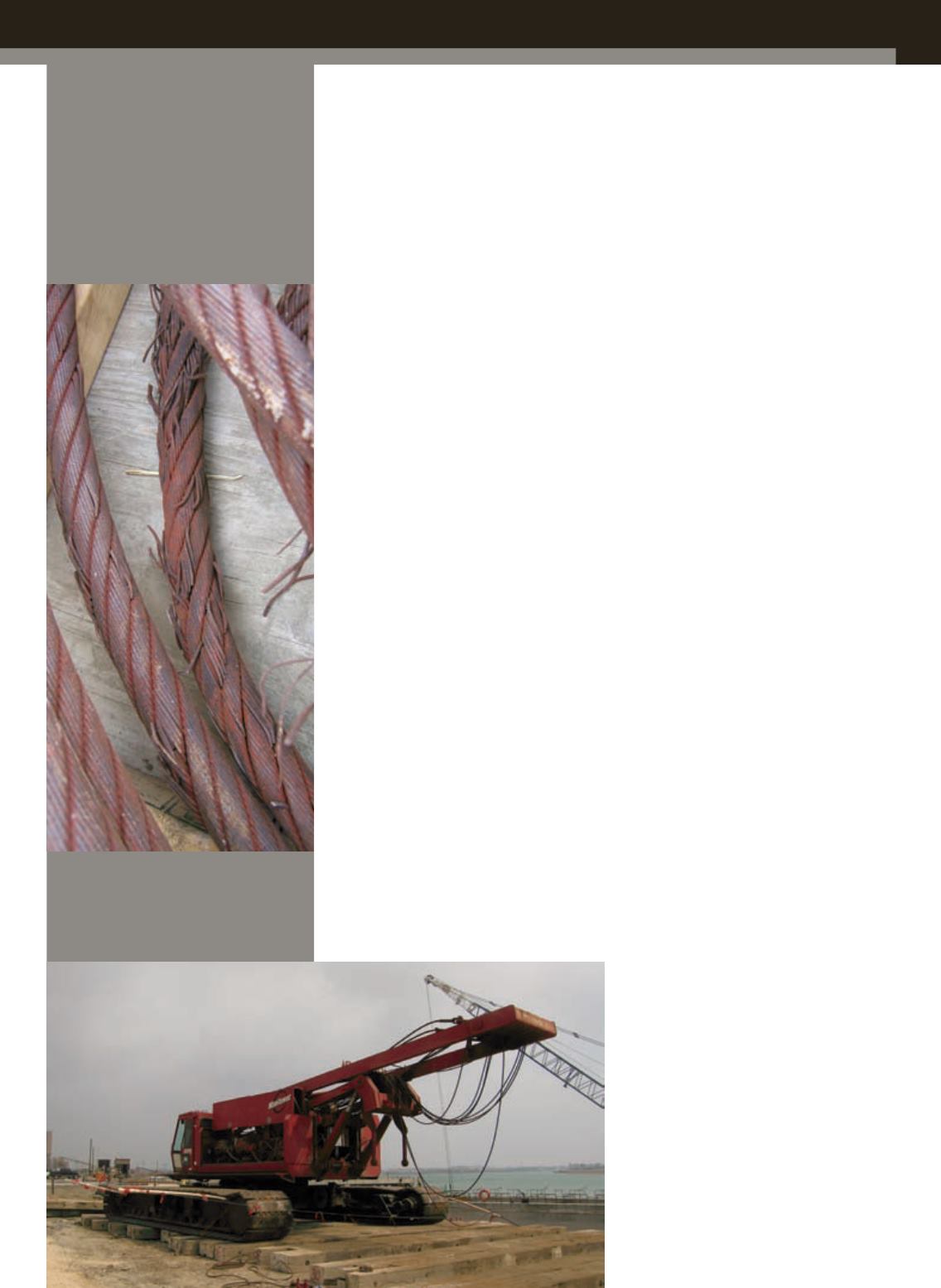

An operator of a Manitowoc Model 888, which was

driving underwater pilings at a dock in Port Isabel, TX,

hoisted the boom up when it gave out and crashed to

the ground. No one was hurt but the cause of the

accident was determined to be out of service

condition wire rope.

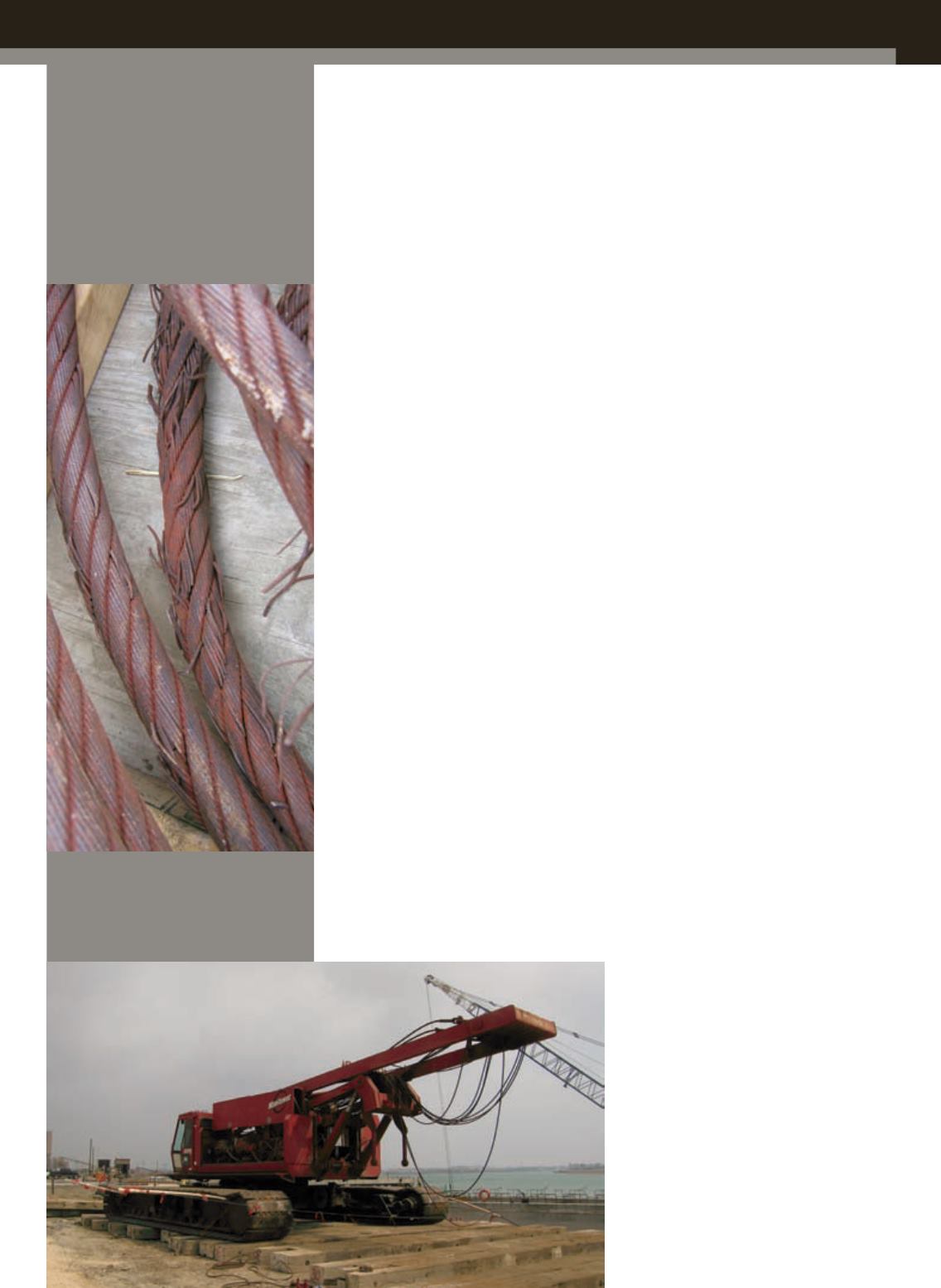

An examination of the failed boom hoist

wire rope revealed that the wire rope

had gone without the proper lubrication.

There were also significant broken wires

within the rope strands.

Wire rope