40

SITE REPORT

LIFTING

ACT

NOVEMBER 2013

For testing, the crane is rigged with 400

feet of main boom, 120 feet of jib and a

20 foot jiblet. It has a capacity to lift 3,000

tons in this configuration, which is the

maximum lifting capacity for the crane.

Lampson International has been building

the Transi-Lift cranes for more than

30 years, but this latest crane has been

updated.

“The difference in this crane and

previous LTL models is that it has a 3,000-

ton capacity front crawler,” Stemp says. “It

also has hydraulic hoisting capabilities,

a larger boom cross section, a newly

designed enclosed engine compartment

and an increase from 1½-inch wire rope to

2-inch wire rope.”

New features

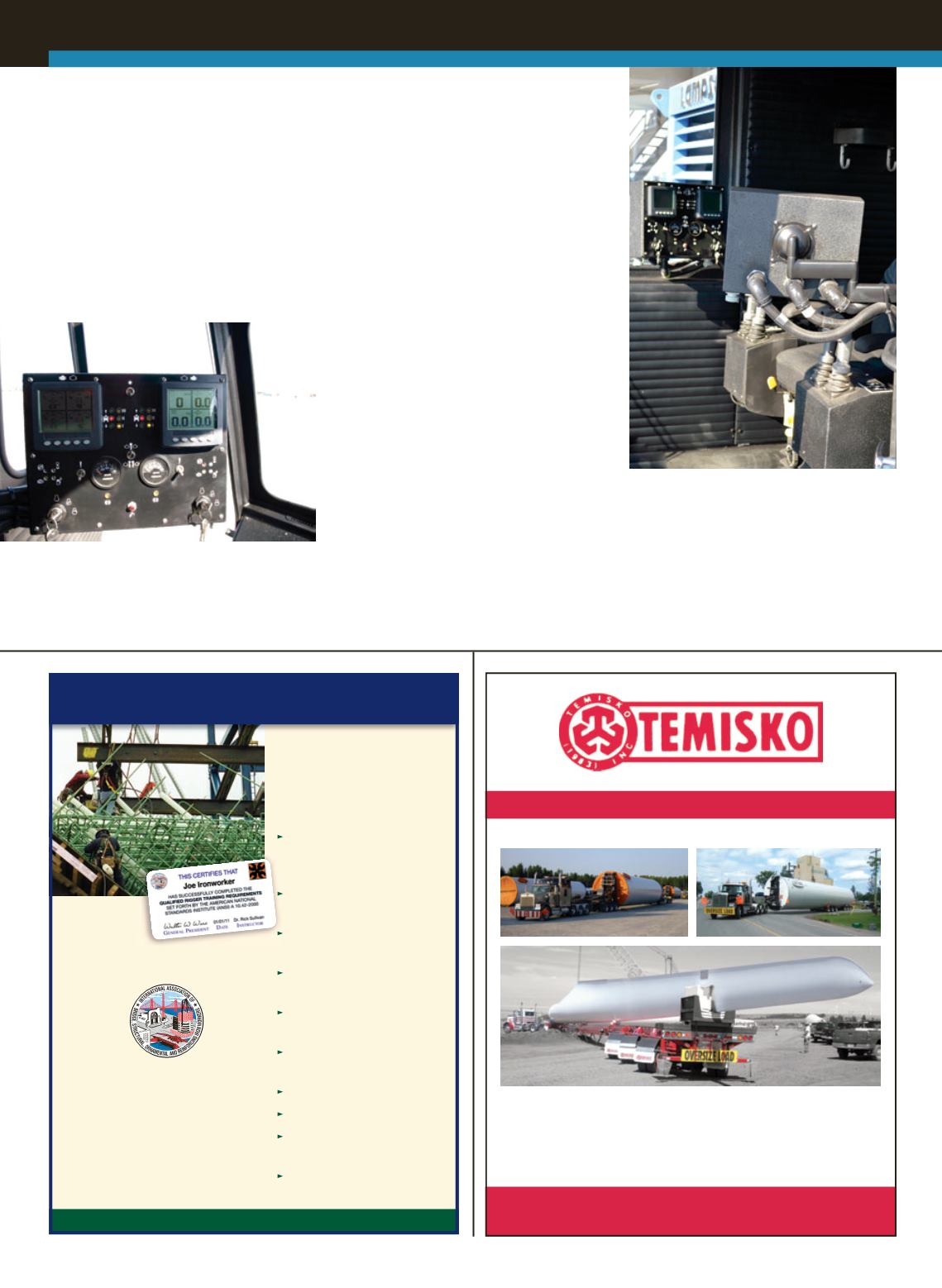

New technologies include a state-of-

the-art electronic hydraulic controls

system and Load Moment Indicator, the

Lampson patented boom design that

totally disassembles for easy shipping,

and the Transi-Lift feature of complete

mobility, Stemp says.

“The crane can perform all operations

while traveling, swinging and

maneuvering in any direction,” he says.

While the crane is still technically

earmarked for the nuclear industry in

Japan, Lampson says the Higashi Dori

project is on hold while the Fukushima

issues are resolved.

When the crane is deployed, she

says it will take on a variety of lifting

assignments. “The many applications

for the Lampson Transi-Lift LTL-3000

include power plant construction, dam

construction, refinery work, bridge

construction and infrastructure projects

as well as sports facilities and stadiums

and manufacturing plants,” Lampson

says.

■

New technologies on this unit

include a state-of-the-art electronic

hydraulic controls system.

The Lampson Transi-Lift LTL 3000 takes

about six weeks to fully erect, and required

four assist cranes, including a 350-ton

crawler, a 230-ton crawler, a 150-ton

crawler and a 60-ton rough terrain crane.

F o l l ow u s o n F a c e b o o k , Tw i t t e r & Yo u Tu b e

Can You Afford

NOT to Hire Us?

w w w . i r o n w o r k e r s . o r g

8 0 0 . 5 4 5 . 4 9 2 1

w w w . i m p a c t - n e t . o r g

Over 3,000

Contractors

& Over 100,000 Ironworkers

Our Customers Receive

these Benefits at

NOAdditional Cost

:

Recognized as Construction

Industry’s Highest Training

Requirements

Ironworker Qualified Signalman

Training meets ASME (B30)

Ironworker Qualified Rigging

Training meets ANSI (A10.42)

80 Classroom Hours of

Rigging & Crane Training

1,200 Hours Minimum of

On-the-Job Training

Trained & Verified by Professional

Ironworker Instructors

State-of-the-Art Training Materials

Online Tracking System

Network of over 150 Training

Centers in the USA & Canada

Certified by the U.S. Department

of Labor

One

RiggingAccident

Could CostYou

Million

$

45 years of innovation and solutions

for your specialized transport!

T: (819) 723-2416 E: