44

ACT

NOVEMBER 2013

with 60- and 100-ton rough-terrain cranes

to a lay-down yard 2.5 miles from the

final erection site. Most notably, the move

involved five blade cages, each holding

three blades with dimensions of 98-feet,

1-inch-long by 10-feet, 8-inches-wide,

by 6-feet-high. Each blade cage weighed

35,274 pounds.

Significant obstacles

Because the project was on private land,

no permits or regulatory approvals were

required. However, since the ranch

served as a private residence as well

as a nature preserve, Omega Morgan

needed to devise a plan that addressed

significant environmental and property

line considerations. Omega Morgan also

required go-aheads from Gamesa, the

original equipment manufacturer, and

McKinstry, the Seattle-based energy

and facility services firm that developed

the wind farm. Omega Morgan devoted

82 man-hours for project planning,

approvals, engineering and planning.

“It was important to the owners of

the ranch for the landscape to retain its

rustic character,” says Project Manager

Kai Farrar. “The transportation company

originally selected for this project

proposed excavating much of the hillsides,

and then straightening and widening the

road to accommodate the oversize load.

That plan was not acceptable to the client.

We looked at the job and considered how

to deliver the components safely and still

preserve the land.”

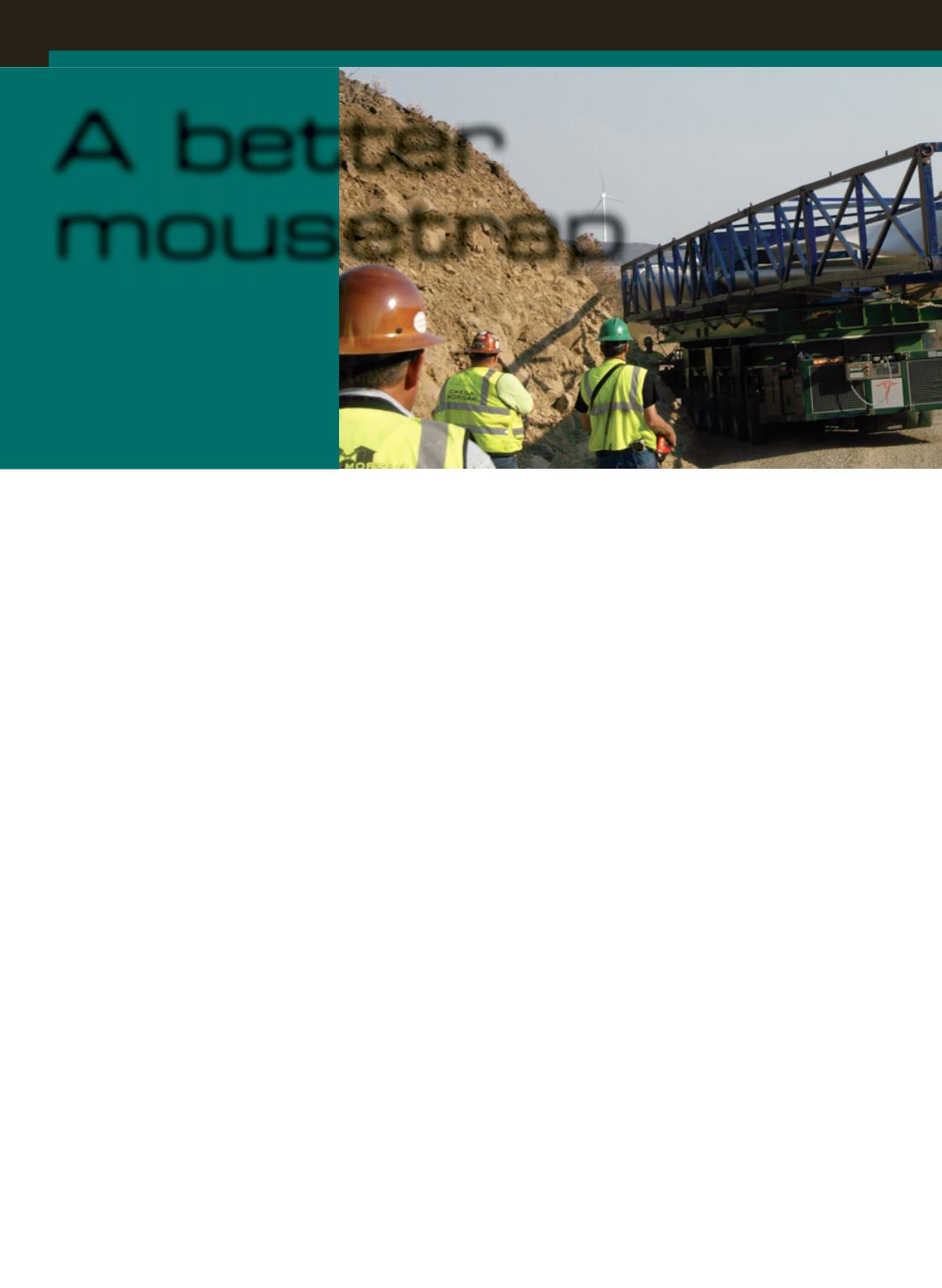

What Omega Morgan discovered upon

inspecting the route was a winding,

narrow, one-lane mountain dirt road,

fraught with hairpin turns, grades of as

W

hen the three

environmentally-conscious

families that own the

Swauk Creek Ranch in Kittitas County,

WA looked to diversify, wind farming

seemed like a possible way to offset the

property’s operating costs. In testimony

to county commissioners, the ranch

owners says they hoped to demonstrate

that such small-scale wind projects can be

economically viable.

Previously, the families had donated

easements on 2,094 acres of the 3,865-

acre ranch to The Nature Conservancy.

Moreover, in an unusual partnership

with the Conservancy, they are funding

ongoing research and restoration work

over the entire ranch. The protected

land includes steep canyons with forests

of Ponderosa pines and native oaks and

is inhabited by elk, cougars, bears and

a wide range of songbirds. Included in

the protected area is one mile of Swauk

Creek, which feeds into the upper Yakima

River and supports 16 native fish species,

including wild Chinook salmon.

The rugged physical elements that made

this land so appealing to the families

and The Nature Conservancy created

formidable challenges for Omega Morgan

of Hillsboro, OR, the company contracted

to move the tower components. Although

considered a small wind project, the

components were large. Each of the wind

turbines would extend 300 feet high

from the ground to the tip of a vertically

extended blade.

The project called for Omega Morgan to

receive the components for five Gamesa

850-kilowatt G58 wind turbines from a

third-party transporter and offload them

much as 20 degrees, and steeply banked

corners. Clearly, a traditional transporter

would be unable to navigate along this

path without massive excavation and road

work.

The route challenges and the client’s

environmental concerns inspired Omega

Morgan to come up with an innovative,

nontraditional solution. Omega Morgan

designed, engineered and fabricated

in-house a custom hydraulically

articulating turntable framework and

mounted it to a self-propelled modular

trailer. This allowed the nearly 100-foot-

long blades to rotate away from the steep

road banks as they were transported up to

the erection site with no environmental

impact.

The unusual nature of the job called

for especially close attention to safety

considerations. Omega Morgan provided

a site-specific safety and evacuation plan

for the duration of the project. Every

crew member carried a two-way radio

for communication, and a portable

defibrillator always was onsite.

The trailer’s fabricator and engineer

were present throughout the entire haul

to monitor the equipment’s performance.

A contingency evacuation plan for the

one-lane road included pull-outs every

1/4 mile, as well as front and rear spotters

in Gators to help spot emergencies and

facilitate a response.

Tailboard meetings were conducted at

every difficult corner. Crews stopped,

walked the corners together and discussed

execution.

The extra precautions paid off when

rain and snow on the road prior to the

haul created extremely soft shoulders. The

Terry White

reports on a

nontraditional solution for

moving wind tower blades

in an environmentally

challenging area.

SITE REPORT

TRANSPORT

A better

mousetrap