27

october 2014

international

construction

FALSEWORKAND FORMWORK

Project pressures

The HK$ 1.8 billion (US$ 232million) South Island railway

scheme is being built to improve transport links to the southern

end ofHongKong, whichdoes not have any rail service.

It will use RMD’s Ascent climbing formwork system to

construct shaft lining, corewalls and tunnel passages.

As part of the project, Leighton-Holland is working on the

LeiTung and SouthHorizon stations and its associated tunnels,

while Nishimatsu Construction is building the railway tunnels

between theAdmiralty andAberdeen stations.

Rory O’Gara, senior project engineer from RMD Kwikform,

described it as among the company’smost challenging projects.

He said, “This is the first time ever we have used our Ascent

climbing formwork in a tunnel application. Previously it has

beenused inhigh-rise commercial or residential buildings so this

project was a global first for the product.

“Having looked at the job itself, whichwas to construct a shaft

lining in the tunnel section, we liaised with our global design

teams for a solution that was both inherently safe and capable of

improving cycle times on the site.

“We would not have initially thought of the Ascent system for

this project, but because it can be pre-assembled in our yard, we

were not only able to offer an innovative new solution to the

challenge, wewere also able to reduce labour costs significantly.”

Indoor ski park

In the Middle East, RMD Kwikform has found its services

equally in demand. One of its biggest projects has involved

working with BesixOrascom on the 162,500m

2

Mall of Egypt

inDubai, UAE.

Describedby itsdevelopers as a“five-star supermall,” it includes

T

he improving picture in many areas of the global

constructionmarket has seen ever-more complex schemes

get underway.

So ensuring the delivery of these projects to precise

specifications, agreed budgets and timelines has influenced the

range of falsework and formwork solutions being offered.

Advances in modular formwork panelling systems featuring

pre-assembled elements have been designed to aid workflow for

project sitemanagers are one response.

This is in addition to developments such as computer-based

management of formwork, warehouse supplies and building

materials, which are increasingly being used on projects and

make difference to the financial viability of schemes.

As IanHayes, division operations director of RMDKwikform

said, there is now a greater sense of positivity from many

companies in, “A market that has been changing as economic

recovery begins.”

So far thisyear,RMDKwikformhasbeen taskedwith supplying

a number of large projects.

This includes providing material for a joint venture between

Leighton-John Holland and Nishimatsu Construction working

on an extension toHongKong’sMTRmetro railway line.

Project pressures

Although construction projects are gettingmore andmore

challenging, there is pressure on falsework and formwork

suppliers tomake their solutionsmore economical and

shave time off schedules.

Neill Barston

reports.

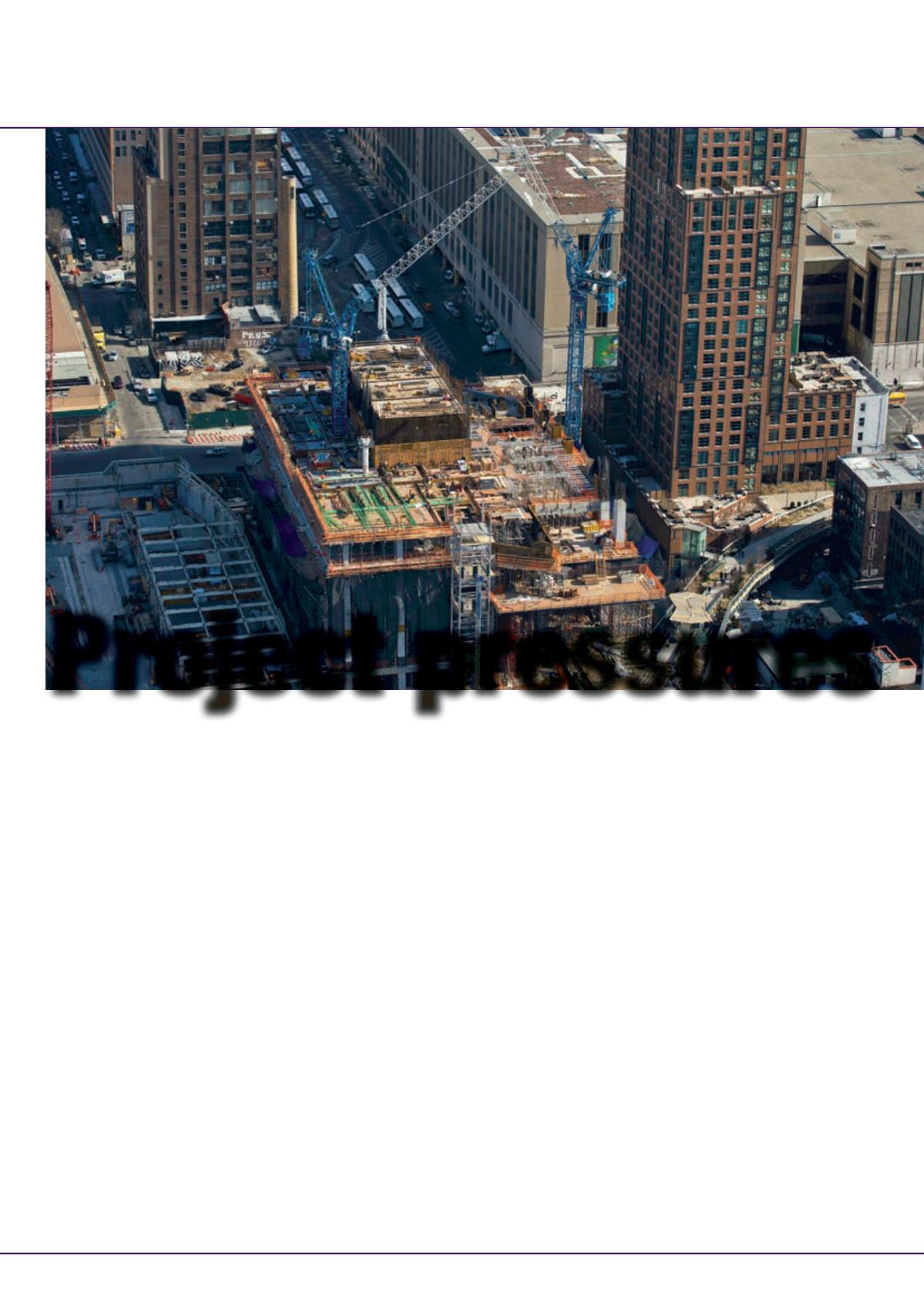

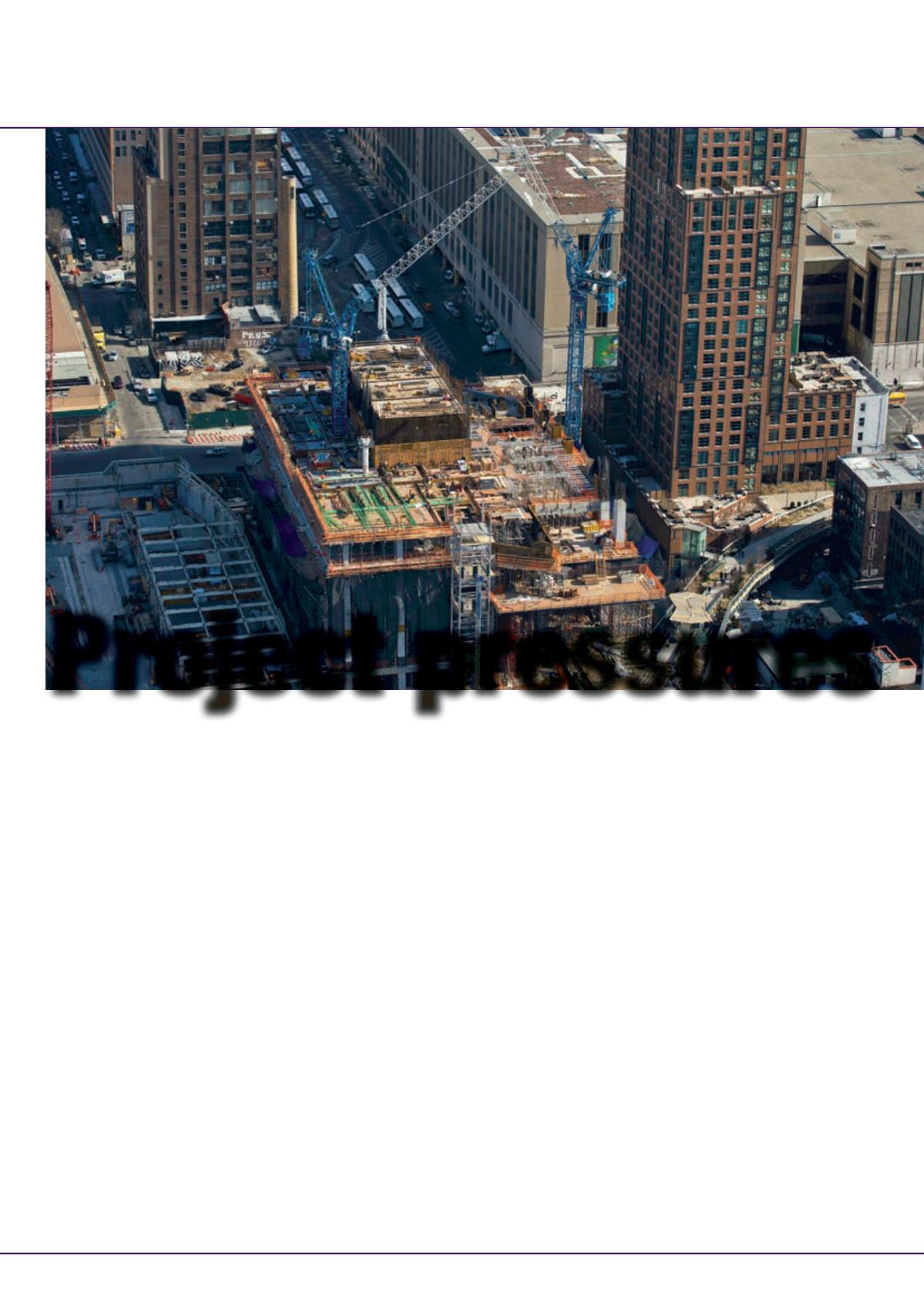

The Hudson’s Yard project in New

York uses Ulma formwork. It is one

of the largest schemes of its kind

in the US.

>