51

january-february 2014

international

construction

>

New technology and new

applications are pushing

the boundaries in the

drilling sector.

Helen

Wright

reports.

Unconventional drilling

T

echnology is a major theme in the drilling equipment

market – from pipe laying to foundations construction

to blast hole drilling in quarries, manufacturers are

concentrating on improving the versatility, efficiency and accuracy

of their products.

Remote performance management devices are becoming more

and more common in the industry, for instance, while innovative

water-powered drilling techniques are also making waves.

Another major trend has seen producers strive to fit more and

more power into ever more compact machines for operation in

tight and hard-to-reach areas.

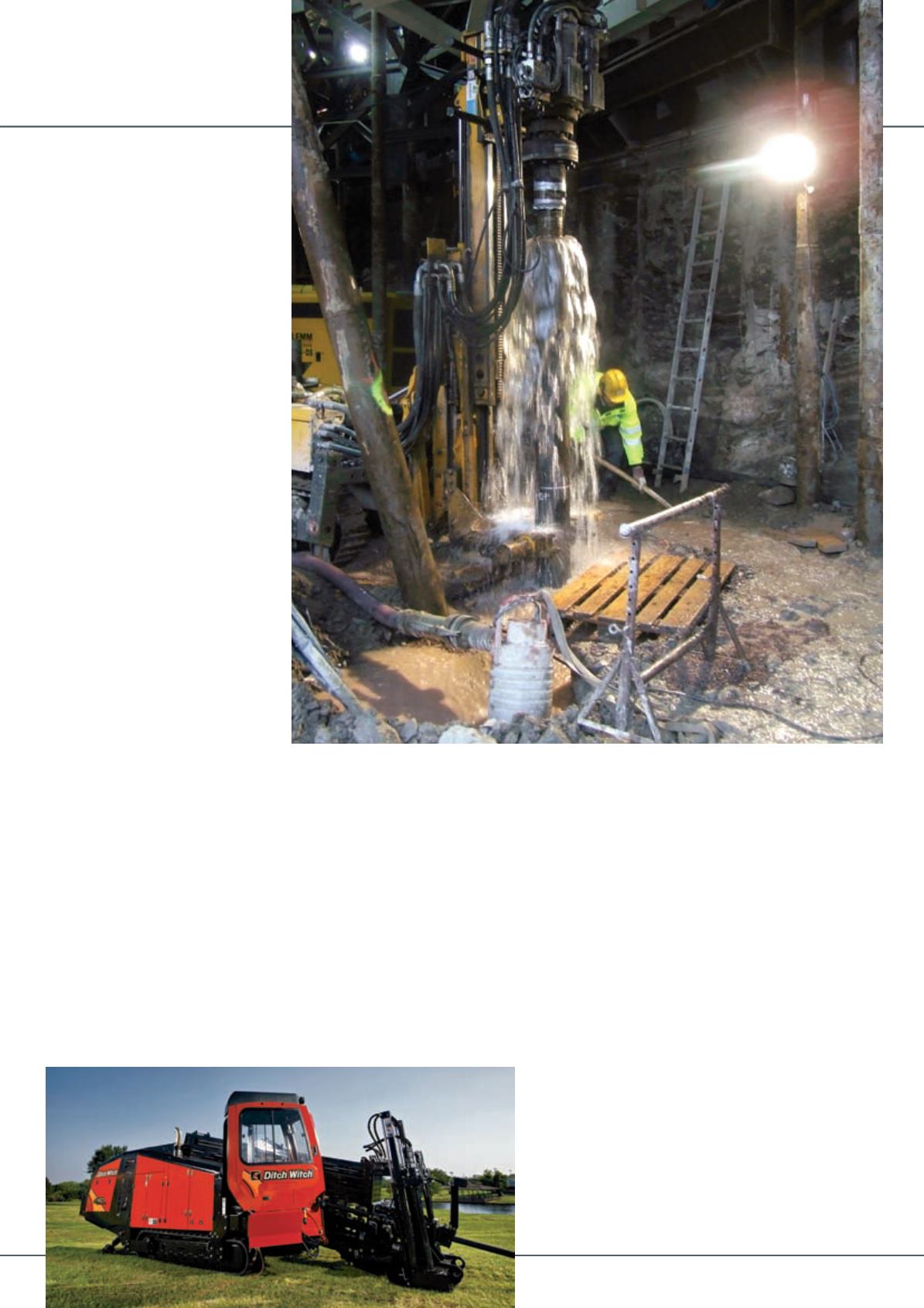

Wassara DTH water-powered drills and

Grindex dewatering pumps are being

used across the Citybanan project in

Stockholm, Sweden.

Ditch Witch’s new Tier 4 Interim-compliant JT60 and all-

terrain counterpart (pictured) are horizontal directional drills

boasting 60,000 lbs (27.2 tonnes) of pullback.

For example, Montabert has launched new drilling attachments

in North America with versatility in mind.

It argues that these drilling attachments require less initial

investment than their conventional dedicated drill rigs, as well as

offering the versatility of being easily transportable between sites

and quickly exchanged for other attachments.

The smaller models, the Micro CPA H22/H25 and Micro CPA

R25/R32 drills, are designed for use on a variety of carriers in the

5 to 10 tonne range — including compact excavators, backhoe

loaders and skid-steer loaders.

The larger CPA 225E drilling attachment is designed for carriers

in the 15 to 25 tonne range. All the new models boast radio

remote control capabilities, and a dust collector is an option on

the smaller Micro tools but comes as standard on the CPA 225E.

The larger drill has a radio remote controlled performance

management system which automatically analyses drilling

conditions and adjusts factors such as feed pressure, feed speed,

anti-jamming controls and percussion pressure.

DRILLING

Unconventional drilling