15

december 2014

international

construction

SITEREPORT

Stuttgart 21

mechanical excavation for its sections of

the project. A spokesman for the group

said the relatively short runs andchanging

cross sections meant tunnel boring

machines (TBMs)werenot suitable,while

the soft ground and urban environment

didnot point todrill&blast techniques either.

The consortium’s chosen workhorses on project are 44 tonne

Liebherr R 944 C Tunnel excavators. The front end of the

machines comprise a swivelling arm with double 45° bearings

and a 4.5 m telescopic boom and 3.07 m arm. The ground is

soft enough to be excavated with a bucket, but the excavators

have high-flowhydraulics available to power attachments such as

breakers or cutters, if required.

In fact the consortium owns three such machines as well as a

24 tonne R 924 Compact Tunnel excavator. For mucking-out

work, keymachines include threeLiebherrL556Tunnelwheeled

loaders and a larger L566Tunnelmachine.

The tunnelling techniques being used follow the general

principles of the New Austrian Tunnelling Method (NATM),

with a combination of shotcrete, steel mesh and some rock

bolting and steel arches being used to stabilise the sides and face.

In the ‘Simone’ tunnel under Stuttgart’s Bad Cannstatt district,

which

iC

visited, thesemethods were achieving progress of some

2.5mper day, with teamsworking 24/7on the project.

Another complication in central Stuttgart is how to cope with

all the spoil generated from the excavations? Trucks would be

problematic in a city which already has

traffic issues, and the environmental

impact would be high due to the long

haulage distances. To mitigate against

this, some areas of the project have been

equipped with an elaborate system of

overhead conveyors, which removes

excavated material without putting more

vehicles on the roads.

Wider scheme

Outsideof thenewurban rail connections

there are still plenty of construction

challenges, partly dictated by Stuttgart’s

geography. The city sits in a bowl carved

by theNeckarRiver,with themain station

sitting at some 230 m above sea level. Building the high-speed

line out to the east will involve the construction of the 9.5 km

Fildertunnel, whichwill take the line to amaximum elevation of

392m, some162m above the city.Groundbreakingon this took

place in July, and upon completion it will be the longest double

tube rail tunnel inGermany.

In fact, of the59.6kmof new trackbeingbuilt for theStuttgart

toUlmhigh-speed stretch, some 30.4 kmwill be in tunnels, and

there will be five such structures 500 m longer or more. Other

significant elements of the scheme include 17 elevated overpasses

and an additional 20 roadbridges.

Benefits

The scheme has not been without its controversies. Indeed, the

wranglesover fundingandalternative schemes, alongwithvarious

objections, took a good 30 years to resolve between project

conception in the early 1980s and ground breaking in 2010.

However,Bahnprojekt Stuttgart-Ulm is keen to stress thebenefits

it will bring, with greater capacity at Stuttgart station, more

destinations for travellers, better connectivitywith the airport and

shorter travel times betweenmajor destinations.

iC

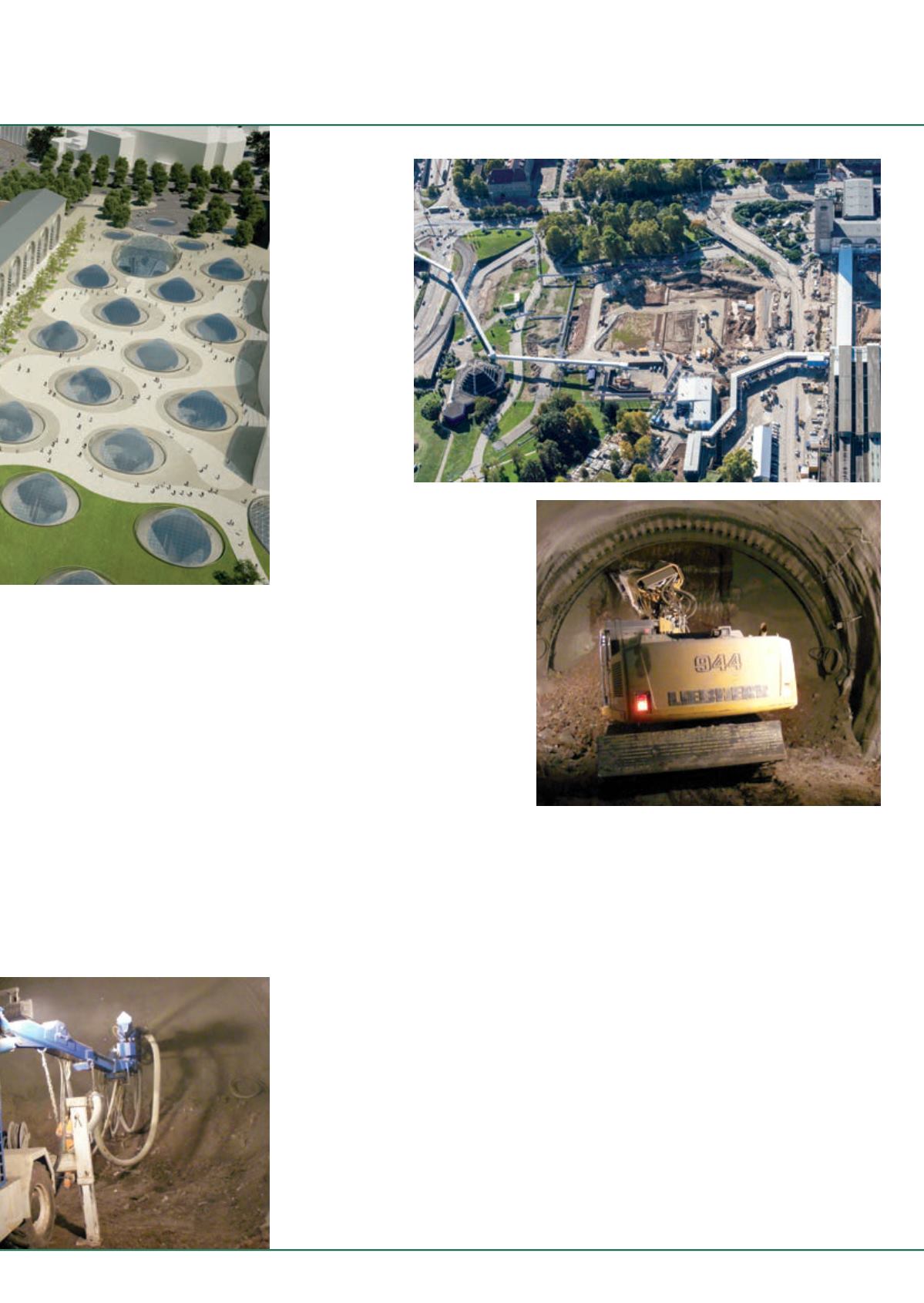

Aerial view

of the central

station area,

with the existing

building top-right.

Covered conveyor

belts have been

installed to

remove excavated

material.

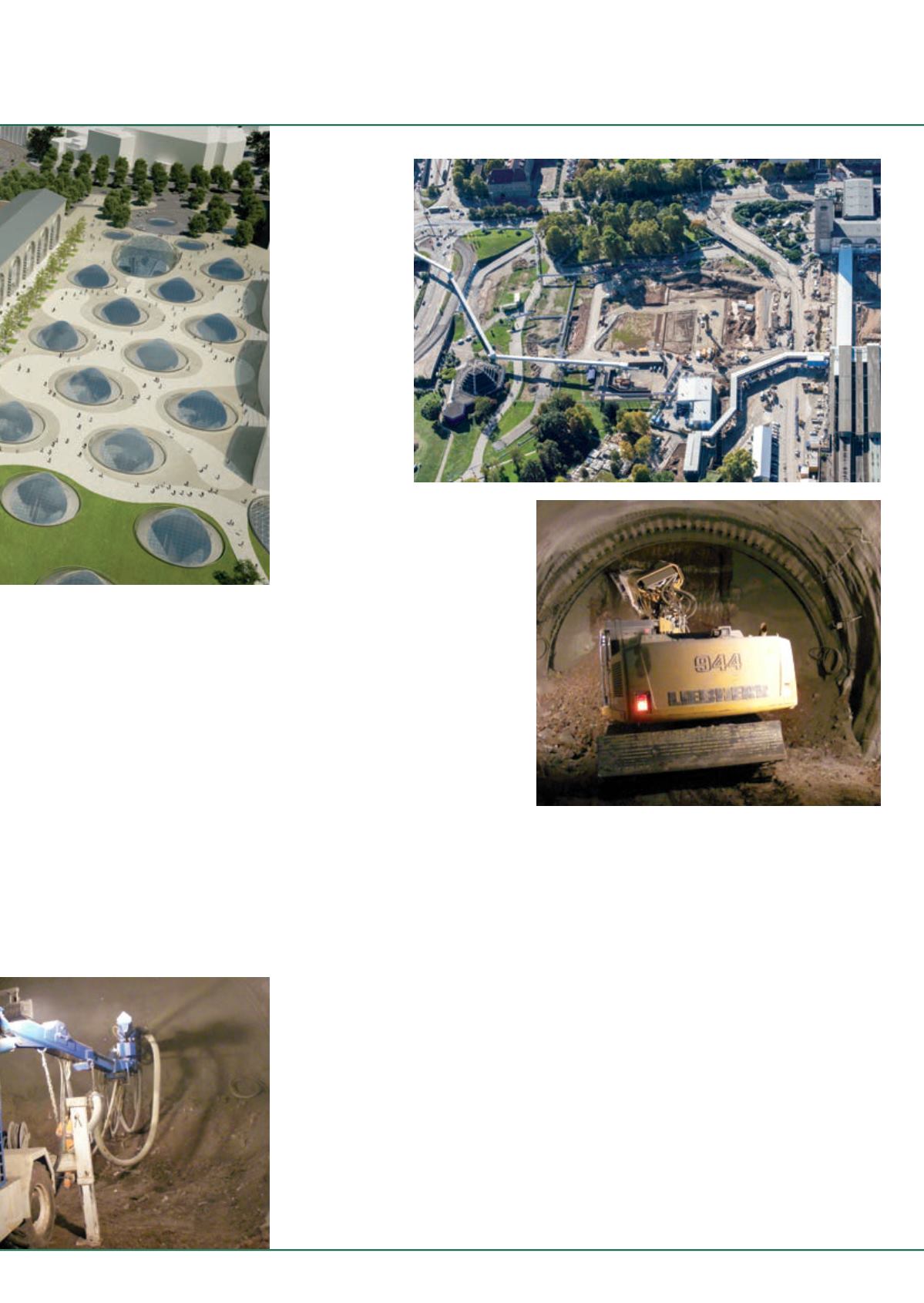

Mechanical excavation using specialised Liebherr Tunnel

excavators is favoured by the ARGE Tunnel Cannstatt

consortium for its city-centre contracts.

Shotcreting to

stabilise the

tunnel walls prior

to excavation of

the heading.