CRAWLER CRANES

INTERNATIONAL AND SPECIALIZED TRANSPORT

■

OCTOBER 2013

18

and luffing jib. The main boom length is

108 m and the luffing jib is 72 m; when

configured with the Ultralift system these

measurements are increased to 121.1 and

84 m respectively, the manufacturer adds.

Power comes from a 447.4 kW Cummins

diesel engine. Also from Sany is the

SCC8150, which can be configured with

an 82 m main boom and a 31 m fixed jib.

Capacity is 150 tonnes and it completes the

range of crawlers, the manufacturer said.

Power comes from a 316 kW Tier 4 interim

refineries. Our new LR 11000 has been

designed according to this demand.”

The LR 11000 is Liebherr’s response to

greater demand in the 1,000 tonne segment,

Beringer explains. An application is

handling offshore wind turbines and their

foundation structures at ports. It fills the

gap between the LR 1750 and the LR 11350.

The LR 11000 can have an S-type main

boom and a W-type luffing jib. It can also

have a Power Boom system with a heavy

luffing jib, the design of which has been

taken from the 3,000 tonne LR 13000.

New from Terex is the 650 tonne

capacity Superlift 3800. The lattice boom

model has a maximum load moment of

8,426 tonne-metres. Its boom system in

SWSL1 configuration is made up of the

main boom plus the luffing jib. The only

attachment needed is the LF, a light

fixed jib.

“Normally crawlers have special boom

combinations, so you have a boom for wind

and a boom for heavy lifting. However, with

the Superlift 3800 there is only one major

boom system, so you can use the same

boom sections for different applications.,"

Jakobs explains. In addition, an assist crane

is not required to erect the boom.

Operating cost is reduced with the

luffing jib, which has a runner with a one

line hook; this means when working on

a project, for example a wind farm, the

operator can lift small objects such as tools,

to the top of the turbine very quickly.

Larger future

The demand for heavy lift crawler cranes

is forecast to continue over the coming

years, especially for the increasing work

in the nuclear and other energy industry

sectors. Whether or not a new generation of

super heavy lifters will emerge to meet this

market demand is something that cannot

be predicted. As Jakobs explains, “Cranes

have to be profitable for the owner. This

means they can take jobs and perform them

efficiently. For us, crawler cranes need to be

efficient and something that will help our

customers with their business.”

“Generally speaking, the job and lift

requirements will dictate what size crane

is utilised,” Collins adds. “In the end, the

lifting needs must justify the crane size and

the cost that comes with a larger crane.”

■

A longer version of this story is at:

Crane and transport service providers Ulferts & Wittrock, Wagenborg Nedlift, and Sarens have

worked together to place a 120 metre long bridge onto 20 m tall piers.

The tied-arch bridge is part of the A23 motorway between Hamburg and Heide in Germany

and crosses over the river Stör. To carry out the lift Wagenborg used a CC 2500-1 and Sarens

used a CC 6800. Ulferts & Wittrock used its new Superlift 3800.

Before the cranes started their work the 1,200 tonne bridge was positioned ready for lifting.

This process involved two modular heavy haulage vehicles moving the bridge to a designated

place on the river bank where a pontoon waited. The first heavy haulage vehicle then drove

onto the pontoon with the bridge; the second

vehicle pushed the pontoon, together with

its load, to the other side of the river, where

a third heavy hauler was waiting. Once the

bridge was in position the three companies

were able to sling the load.

For the lift the CC 6800 was configured

with a stationary 50 m SSL configuration and

was positioned on one side of the bank. On

the opposite bank was the CC 2500-1, which

was set up in a 42 m SSL configuration, and

the Superlift 3800, which was set up with a

42 m main boom. Together the cranes

lifted the 1,200 tonne bridge into position.

Challenges during the lift included

synchronising all three cranes so the load

could be balanced.

Despite the challenges and the rain, the

bridge was put onto the 20 m piers in

five hours.

TEAM PUTS TEREX TRIO TO WORK

Cummins engine.

“The SCC8150 gives contractors a new

option in a competitive segment of the

market,” Kyle Nape, senior vice president,

Sany America Lifting Group, says. “Our

new crane delivers a combination of

control, performance, operator comfort,

power and dependability that meets and

exceeds the requirements for a machine in

this weight class.”

Heavy lifters

Over the last 12 months there have been

some new additions to the crawler crane

market at the higher end of the capacity

scale. Although there are nearly no limits

to how much a crane can lift, the higher a

crawler’s lifting capacity, the greater is the

design challenge.

“Concerning lifting capacity there are

nearly no limits,” explains Beringer, “but

these huge cranes include counterweight

systems that need a lot of space. So the

challenge is to design cranes which can

work in constricted areas, such as in

The cranes in position on

either side of the river

The bridge is put into place ready for lifting

The 650 tonne

Terex Superlift

3800 lattice boom

crawler crane has

a maximum load

moment of 8,426

tonne-metres

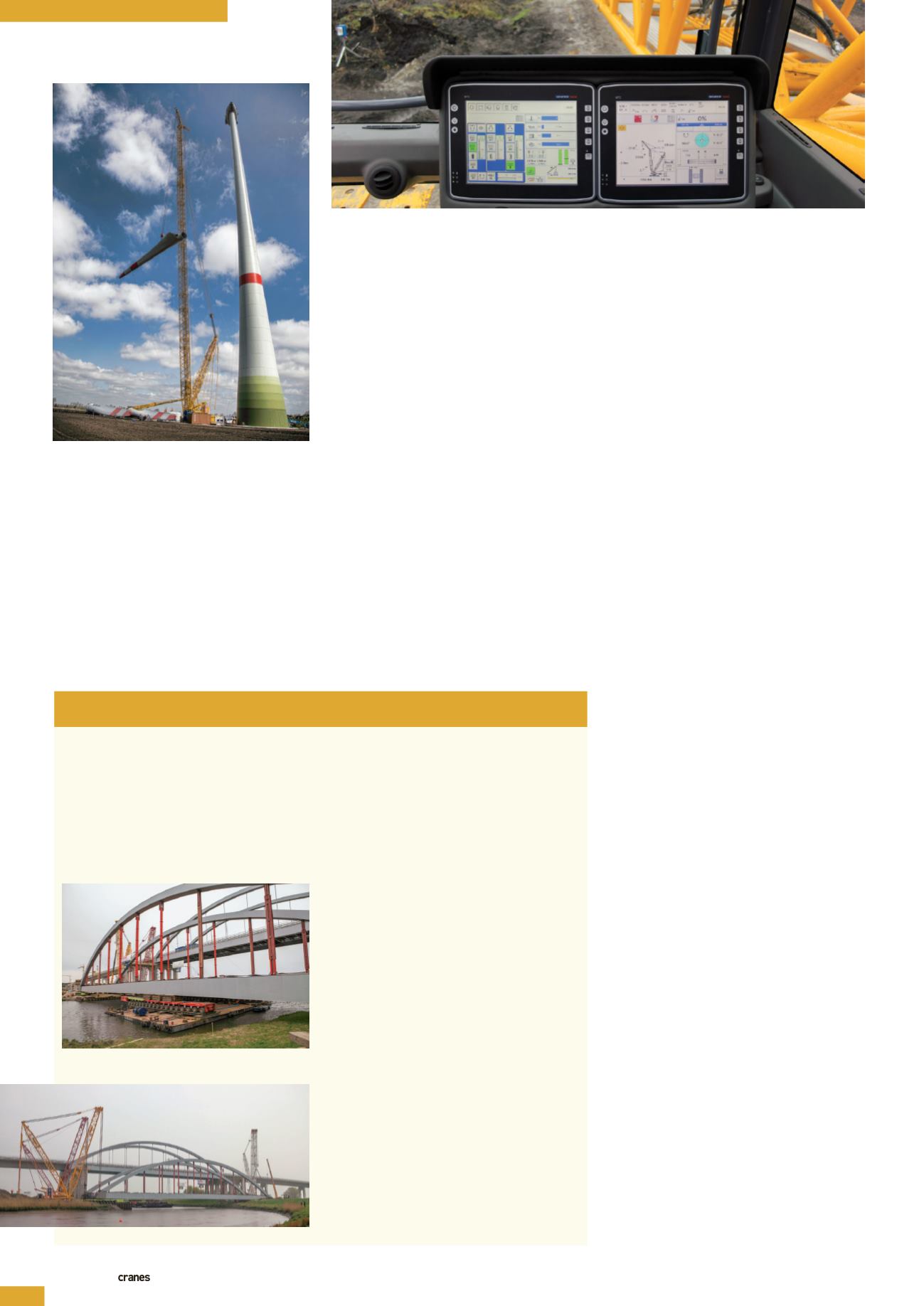

Inside the cab

of the 3800

of a Superlift

3800